Patents

Literature

35results about How to "Simplify the machining process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

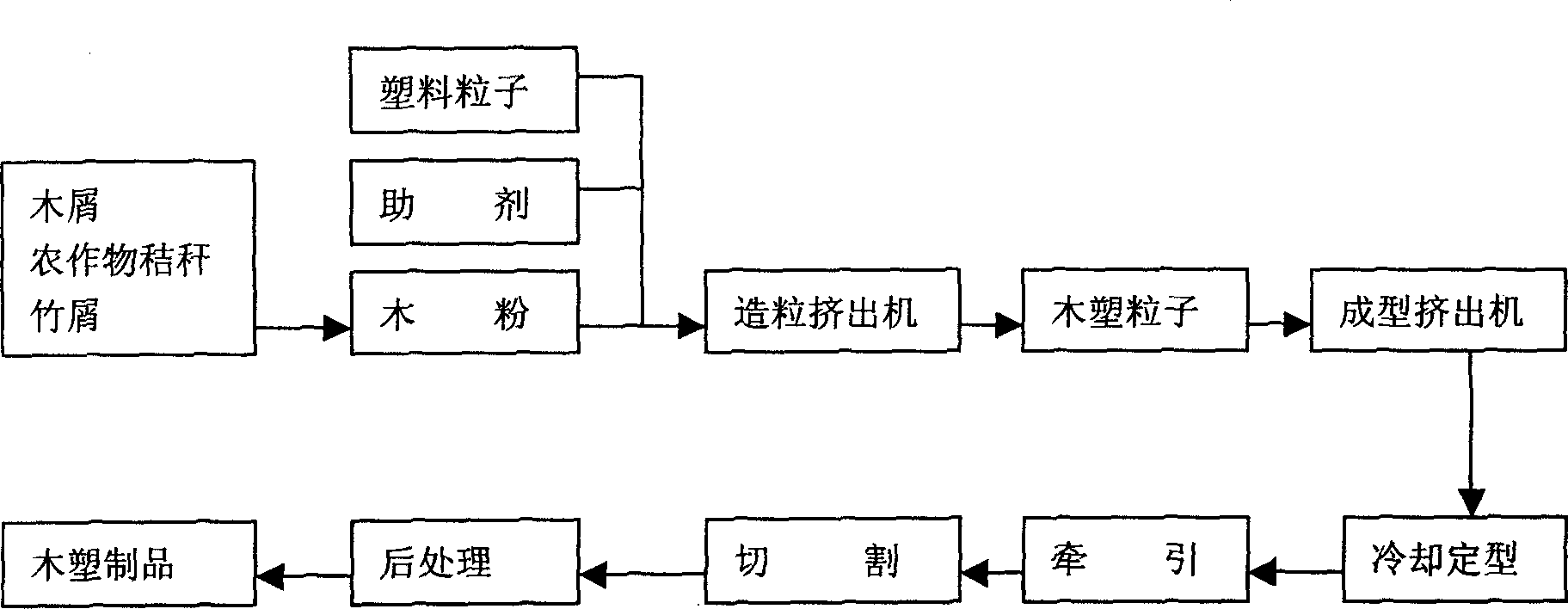

Making process of compound wood-plastic material product

The present invention discloses the making process of compound wood-plastic material product. Un-dried wood powder, plastic grain, compatibilizing agent, coupler, antioxidant, reinforcer, color powder and lubricant in certain proportion are fed to a pelletizing extruder for form granular material; and the granular material is extruded in a forming extruder and further processed through cooling to settle, drawing, cutting and decorating to produce the wood-plastic product. The present invention has the advantages of simple process, high production effect and rich material resource, and the product has timber-like texture, excellent performance and environment friendship.

Owner:浙江诚信包装有限公司

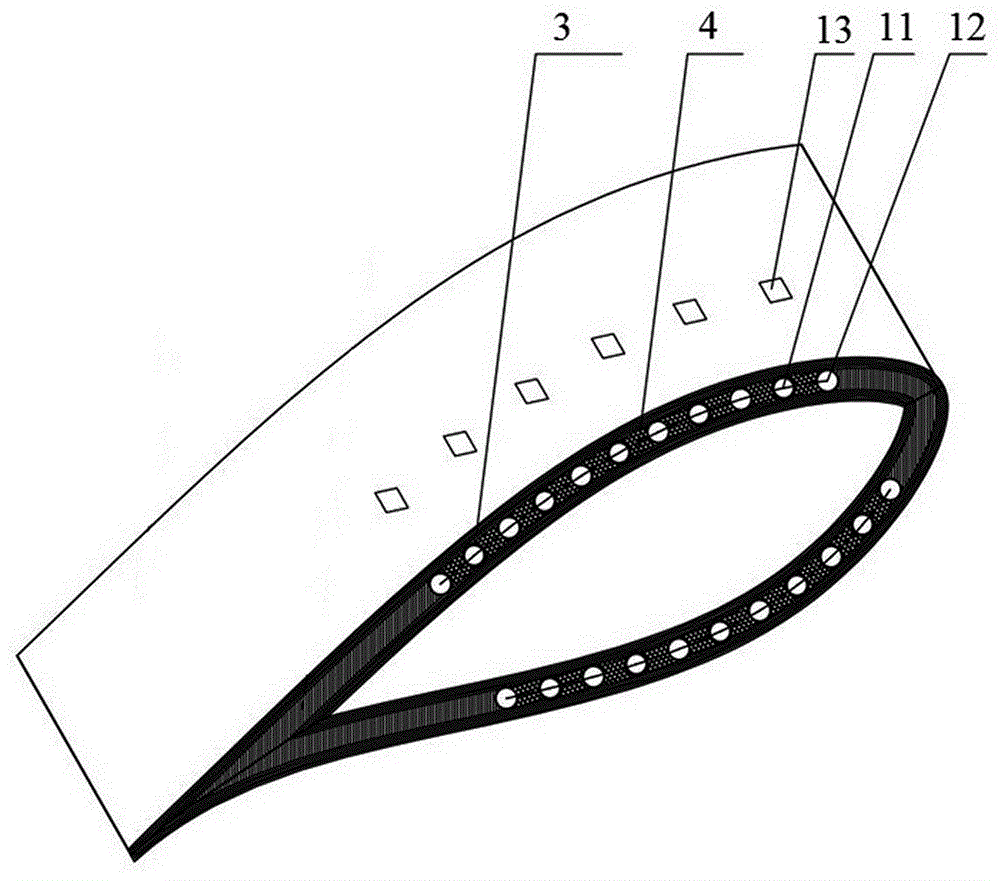

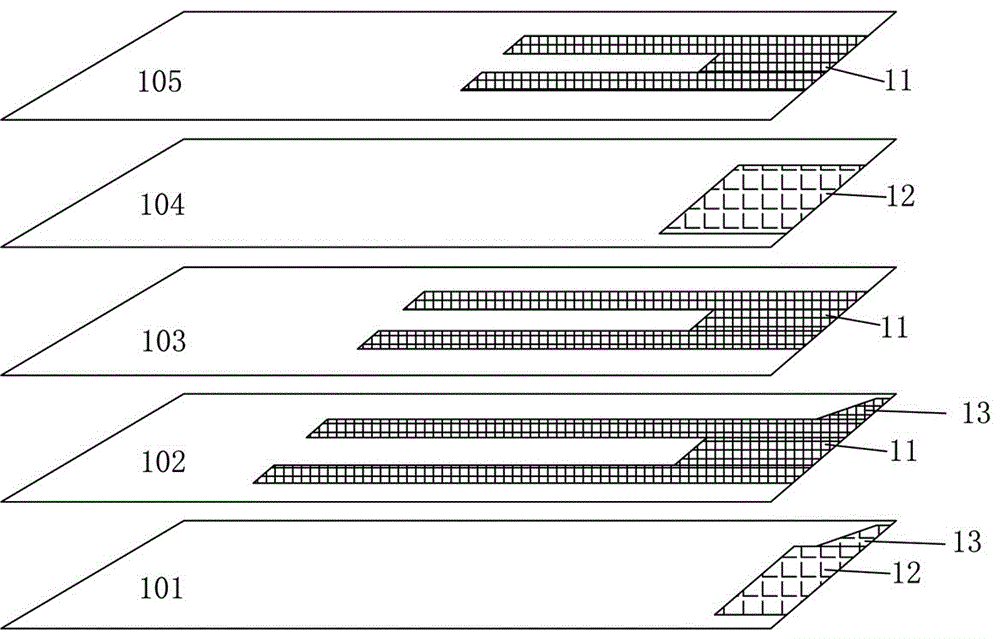

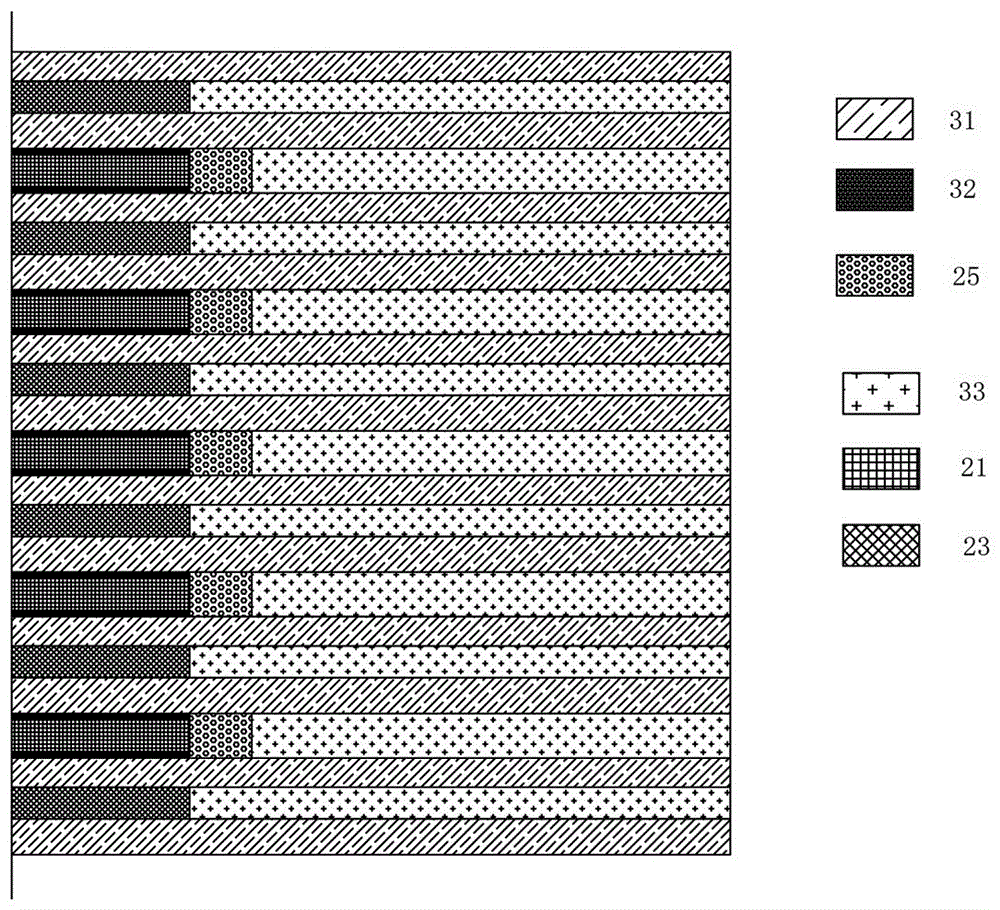

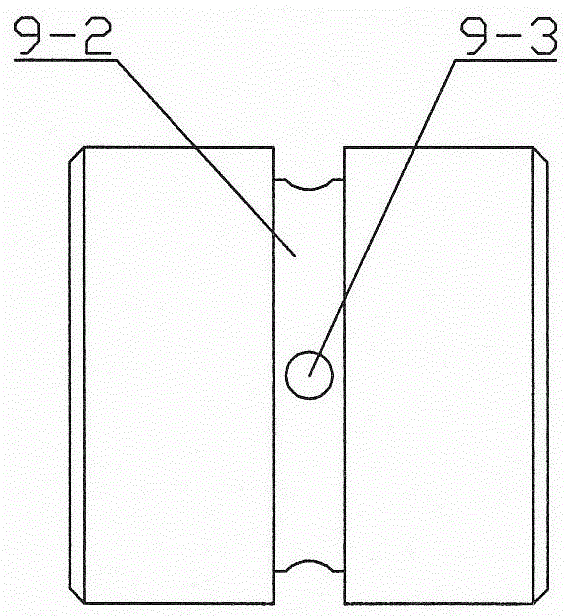

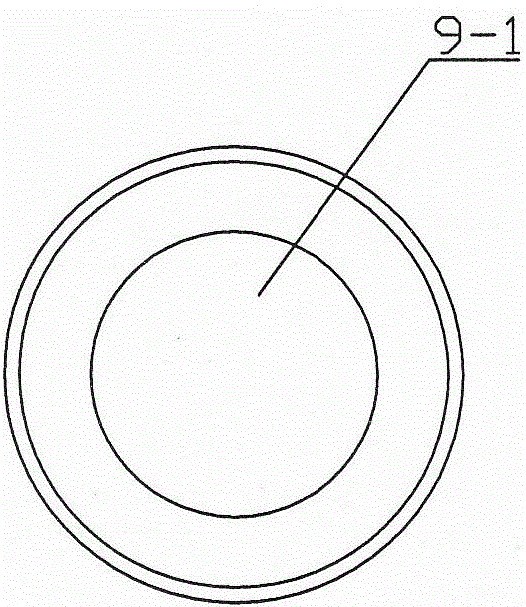

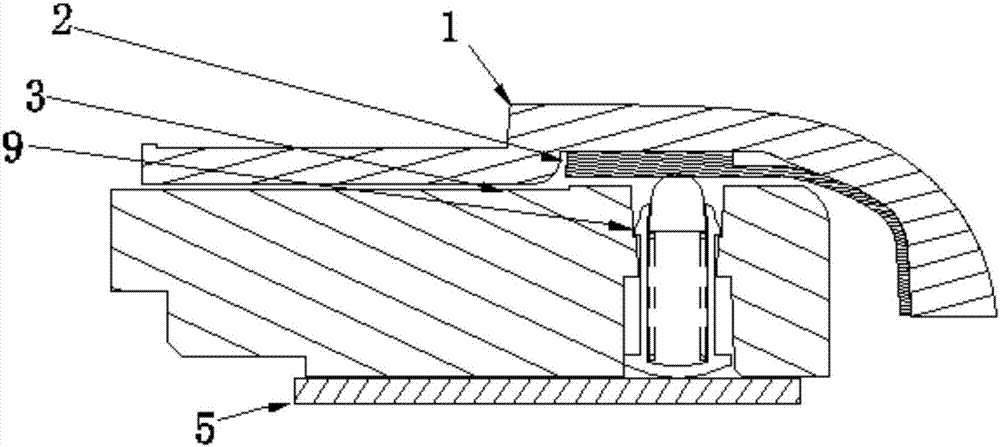

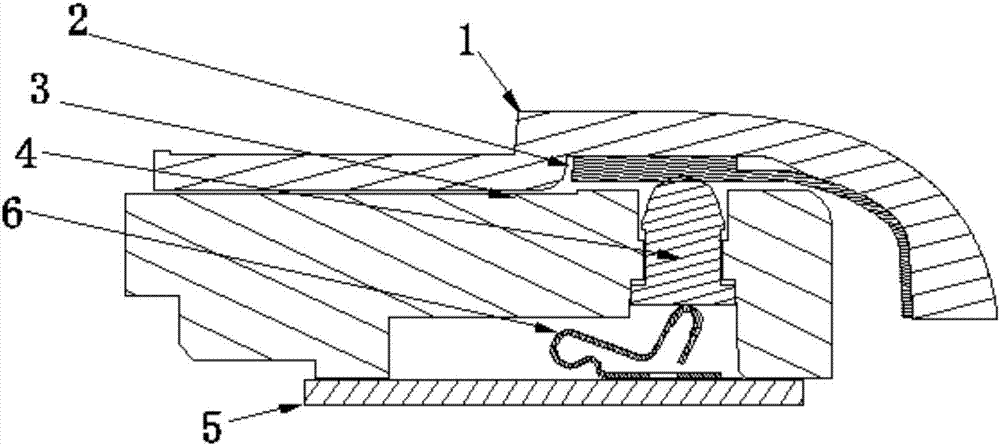

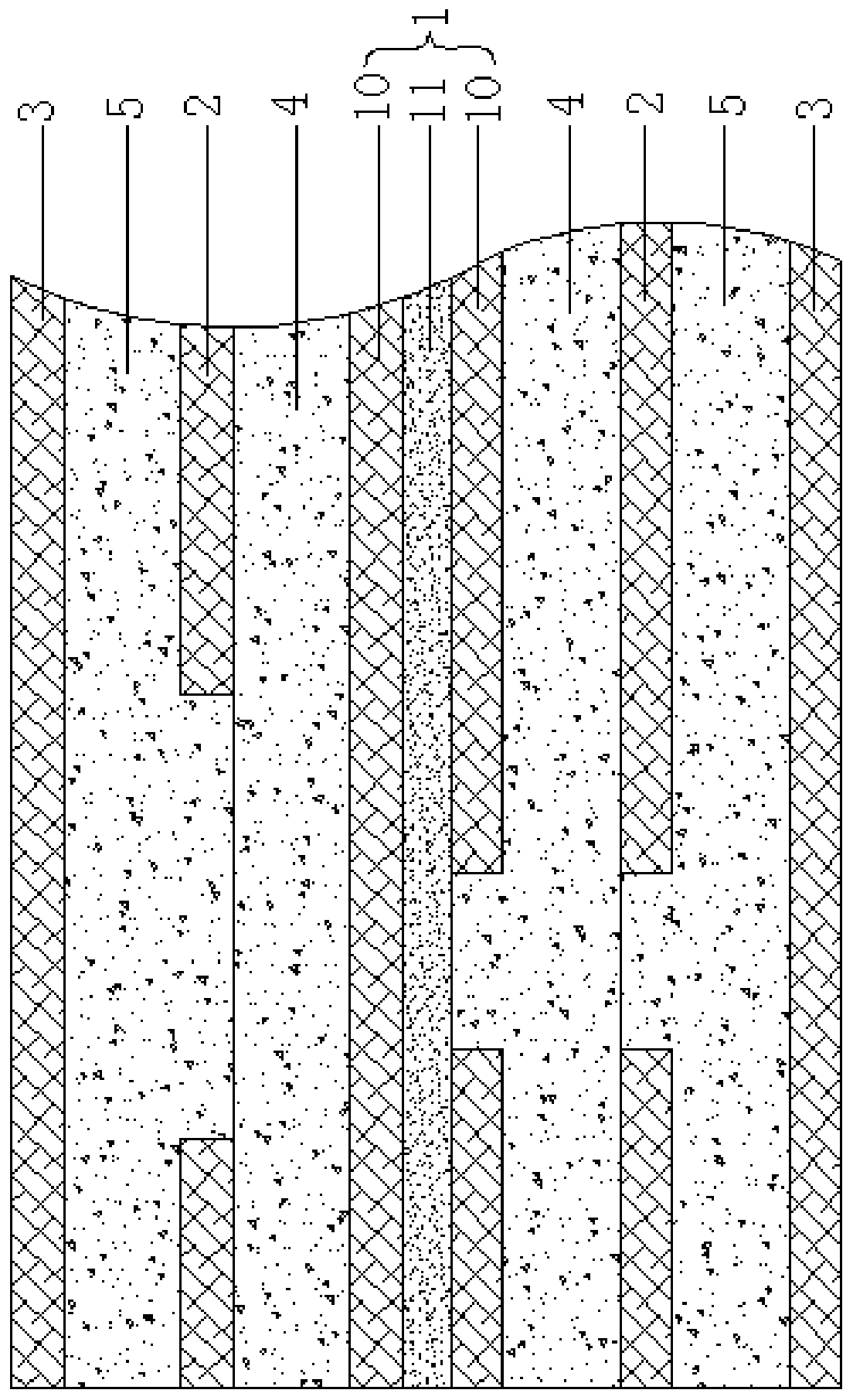

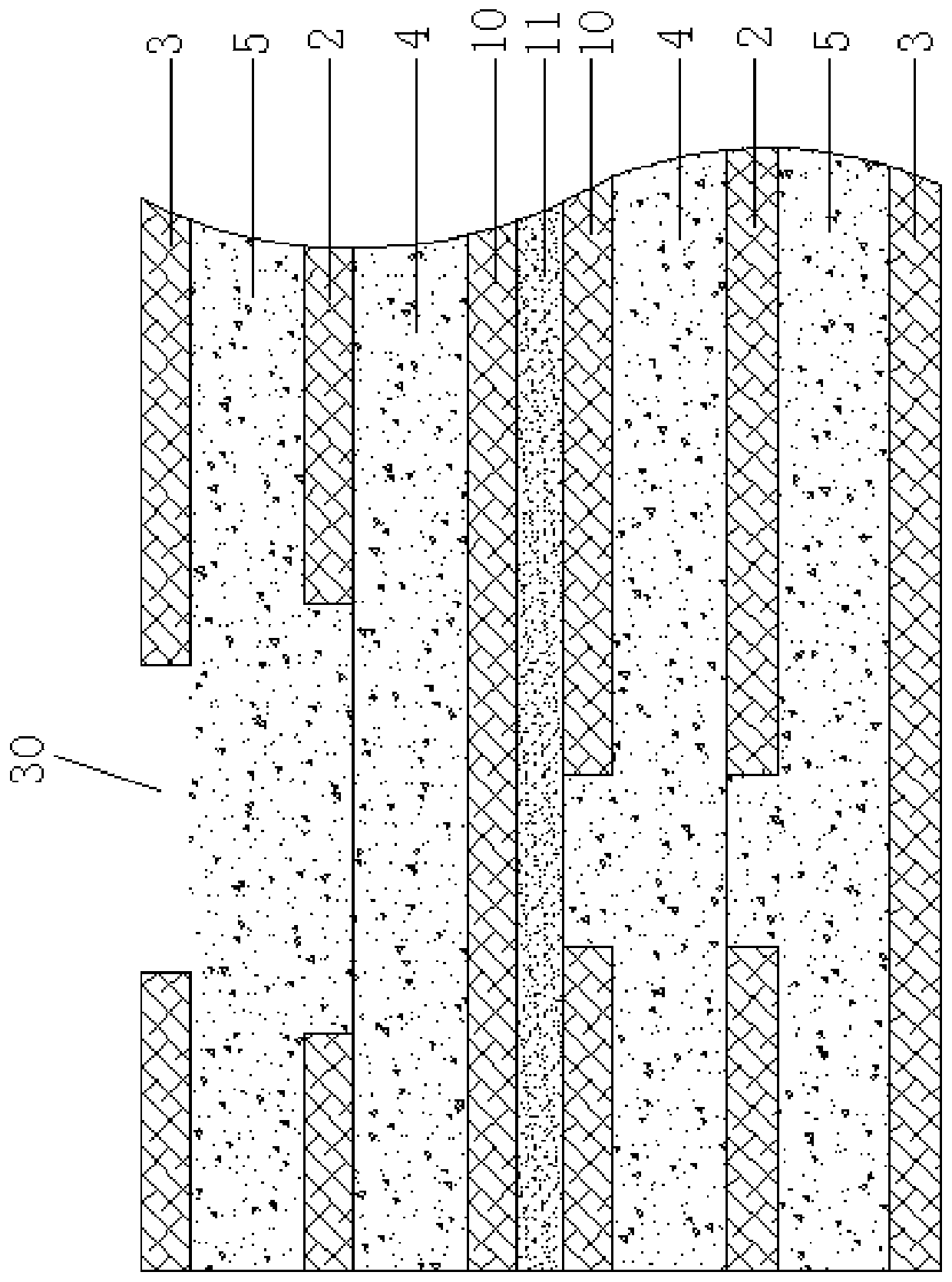

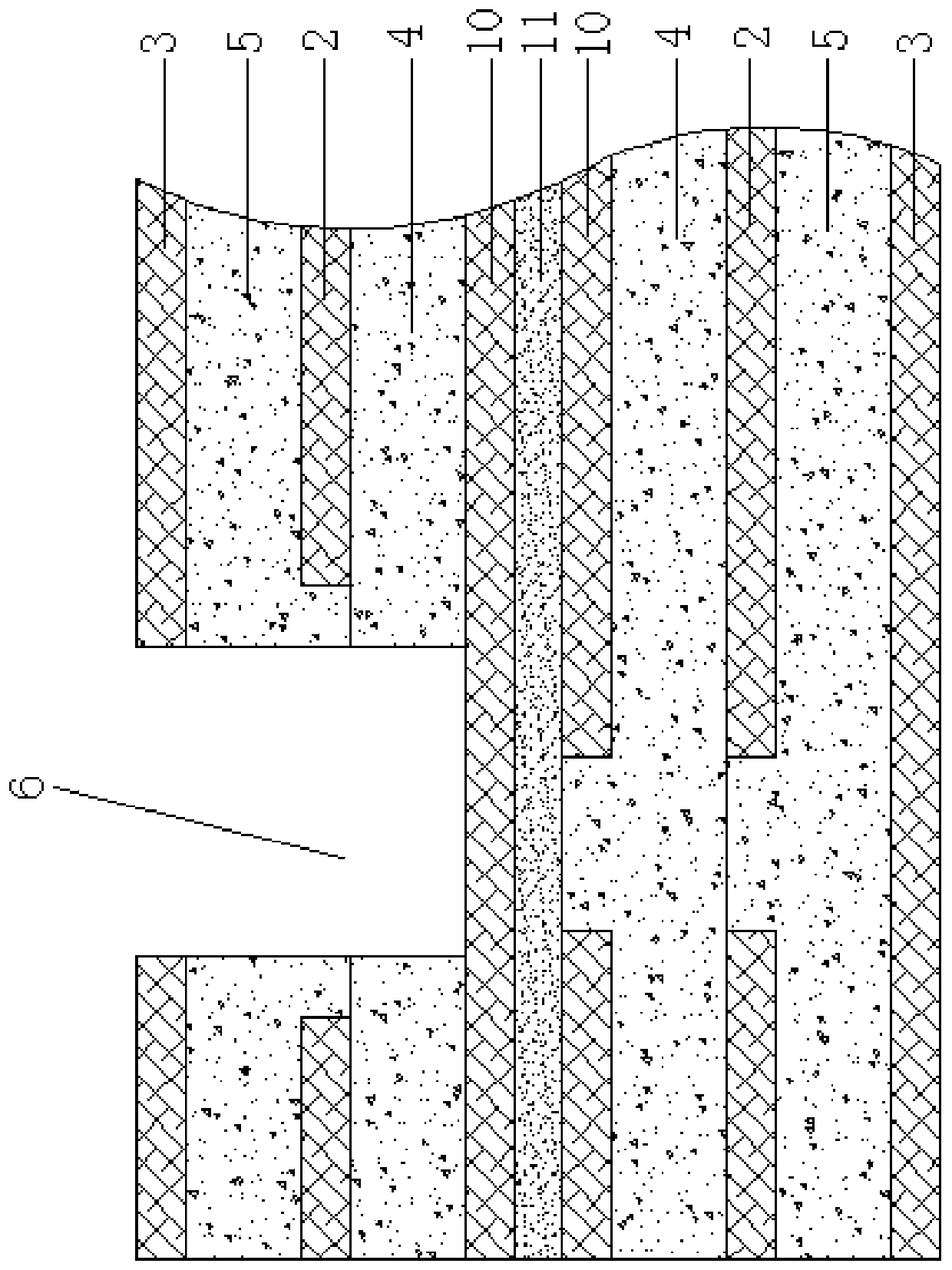

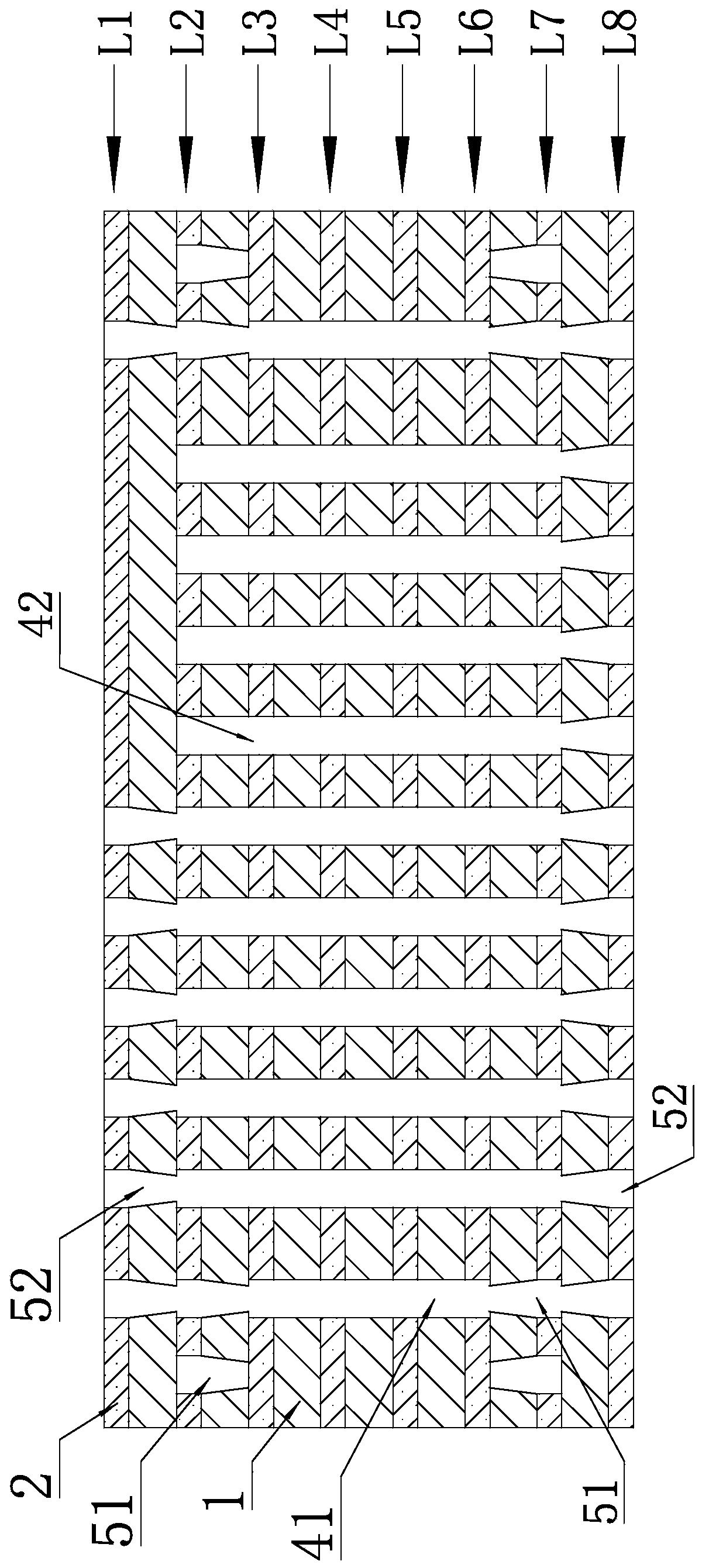

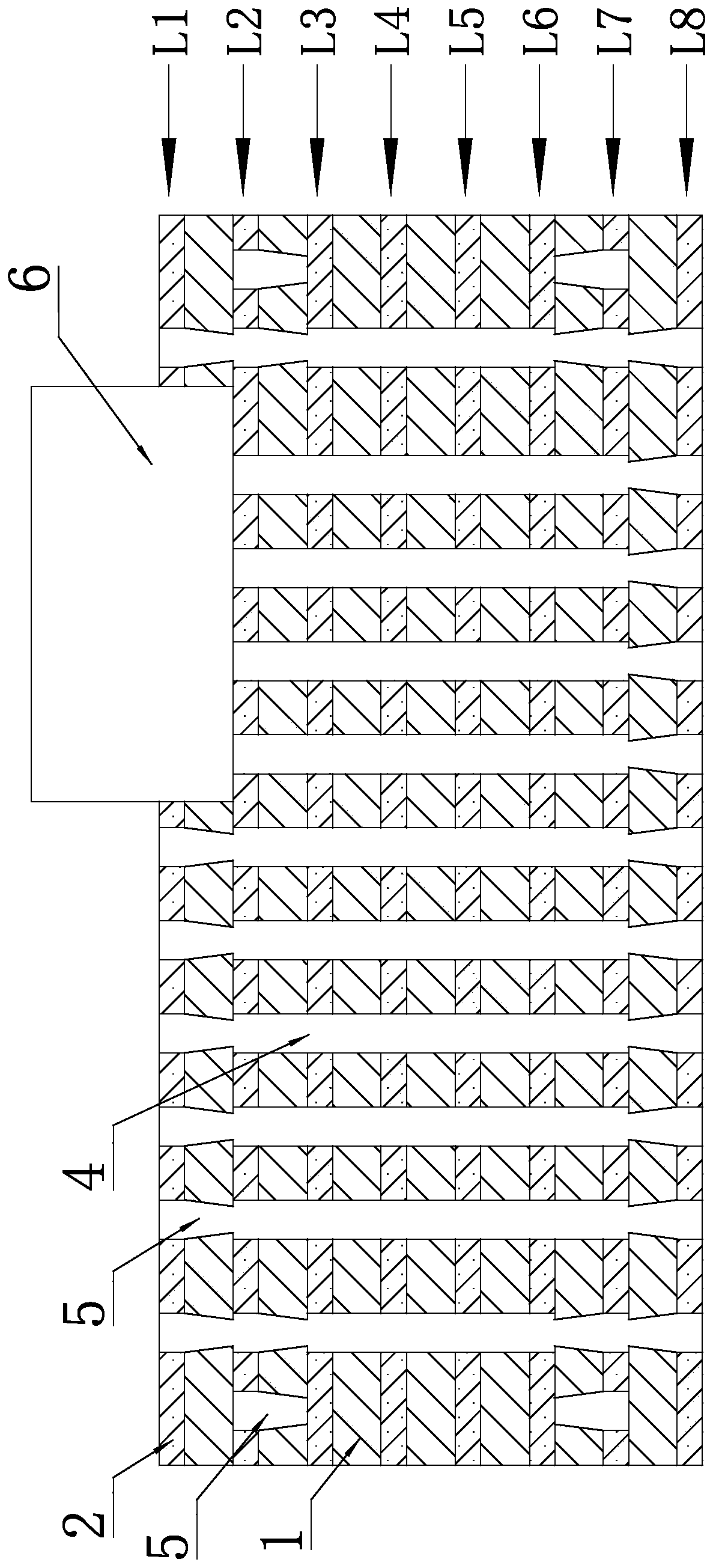

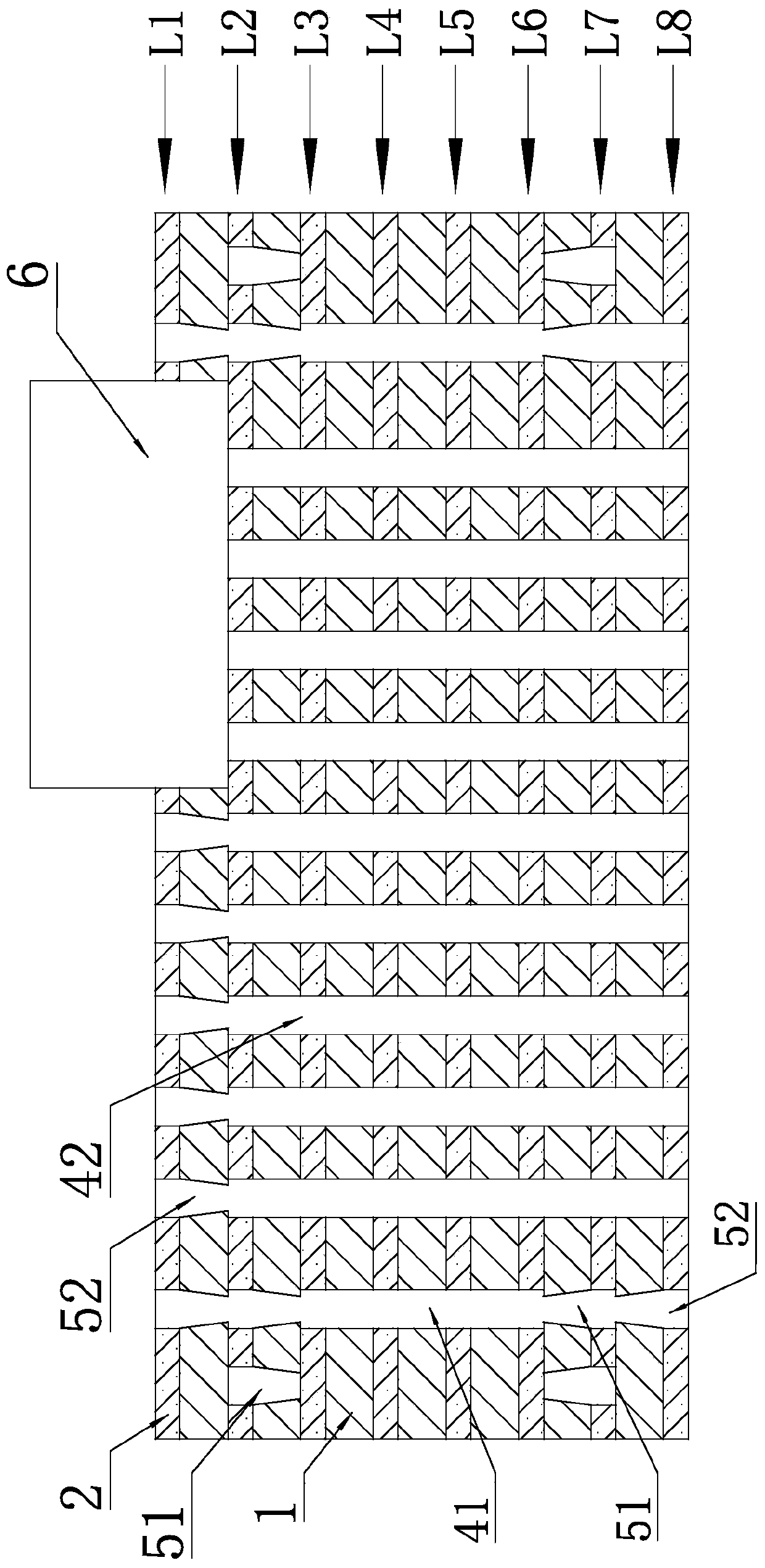

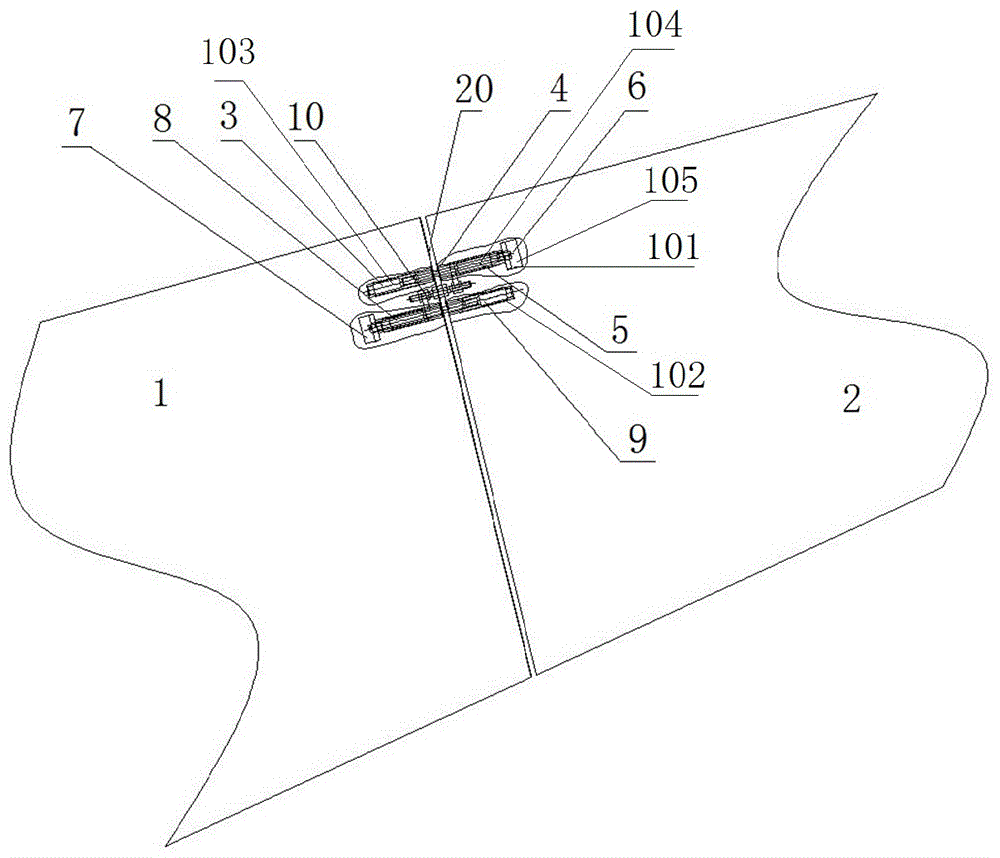

Wind power blade and manufacturing technology thereof

ActiveCN105952580ACompact structureSimplify the machining processFinal product manufactureMachines/enginesLap jointWrench

The invention provides a wind power blade and a manufacturing technology thereof, and aims to solve the problems that in the prior art, the blade weight is increased due to a metal connecting barrel and the processing procedure is increased due to manufacturing of a leaf-shaped skeleton. The manufacturing technology comprises the steps of fixation of flanges, laying of upper and lower reinforcing layers of an embedded part, arrangement of bolt sleeves and light sleeves, arrangement of wrench space blocks, lap joint of wedge-shaped strips and beam caps, splicing of connecting locating pins and segmental shells, and connection of segmental blades for an integral blade. According to the manufacturing technology, connecting structures of the segmental blades are more compact, the mechanical processing procedure is simplified, laying layers of the beam caps and the wedge-shaped strips are integrally designed, the thicknesses of the laying layers of the beam caps and the wedge-shaped strips are decreased, the rigidity of the blade is guaranteed to smoothly transit, the fatigue strength of a composite at segment connection parts is improved, and the blade weight is decreased; and unidirectional fiber composite laying layers are spliced in the chordwise direction, and composite laying layers are added among the layers, so that resin is guaranteed to uniformly permeate during suction injection, the torsional rigidity of segmental parts is improved, and smooth transmission of the local load of the segment connection parts of the blade is effectively guaranteed.

Owner:BAIYIN SINO WIND ENERGY

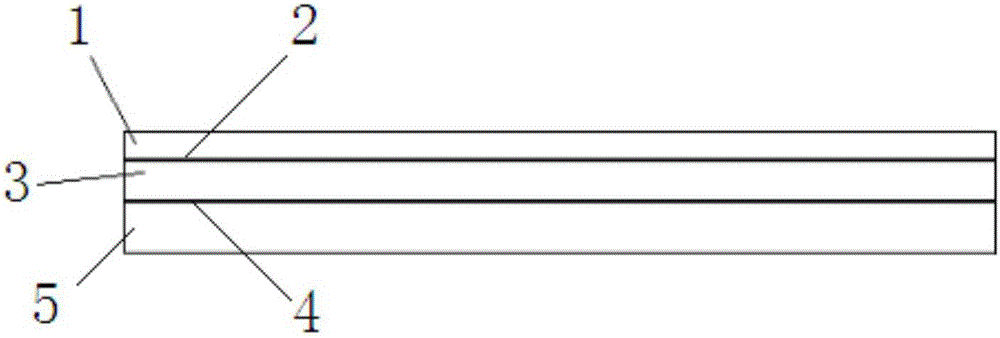

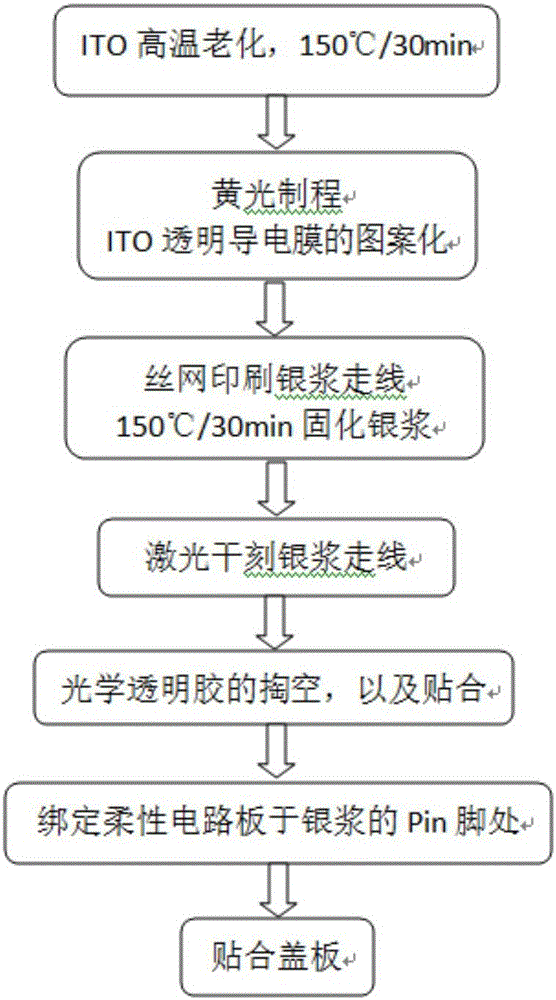

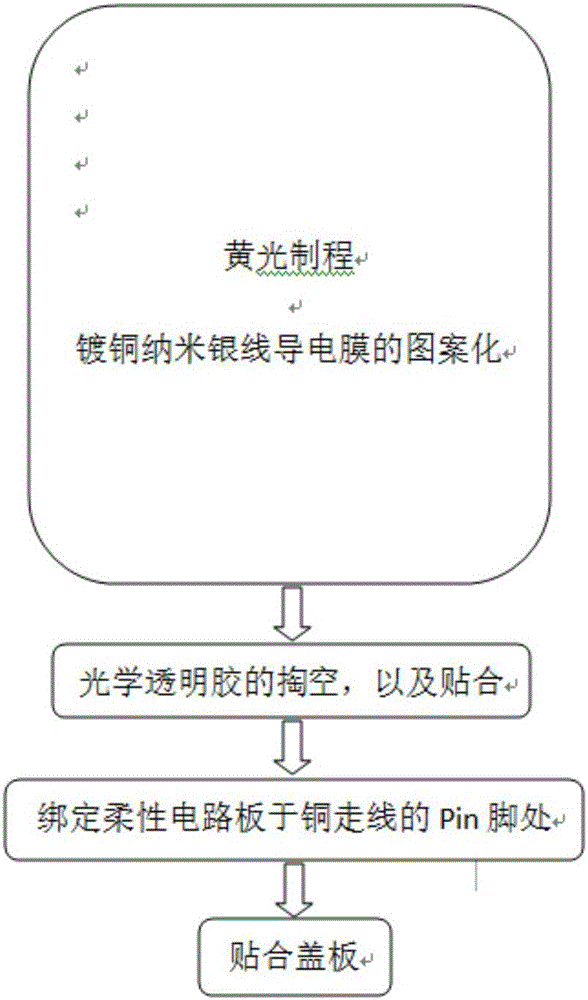

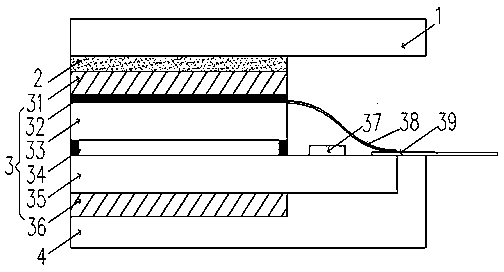

Copper-plated nanometer silver wire touch screen and manufacturing method thereof

ActiveCN106095176ASimplify the machining processReduce processing costsInput/output processes for data processingCopper platingAnisotropic conductive adhesive

The invention discloses a copper-plated nanometer silver wire touch screen which comprises a cover plate made from hard materials or soft materials. An optical transparent adhesive, a touch sensing element, an anisotropic conductive adhesive and a flexible circuit board are sequentially stacked on one side of the cover plate. The cover plate and the touch sensing element are adhesively connected through the optical transparent adhesive. The flexible circuit board is connected with the touch sensing element through the anisotropic conductive adhesive. A manufacturing method of the copper-plated nanometer silver wire touch screen comprises the steps that yellow light process is carried out, and patterning operation is carried out on a copper-plated nanometer silver wire conductive film; the optical transparent adhesive is hollowed according to design; the flexible circuit board is bound to the touch sensing element in the step 1 through the anisotropic conductive adhesive; the cover plate and the touch sensing element are attached through the optical transparent adhesive, and the product is obtained. The manufacturing steps can be simplified, production efficiency is improved, the product yield is improved, and the copper-plated nanometer silver wire touch screen and the manufacturing method therefore are widely applied to various touch screens and manufacturing methods thereof.

Owner:佛山市瑞纳新材科技有限公司

ON CELL solid-state full lamination module processing method

InactiveCN104360762ASimplify the machining processImprove assembly accuracyLaminationLamination apparatusOn cellsLiquid-crystal display

The invention discloses an ON CELL solid-state full lamination module processing method which comprises the following steps: bonding a DRIVER IC at an IC MASK of a TFT substrate under an ON CELL TFT liquid crystal display, then bonding a touch SENSOR FPC at a PIN outlet end of an ITO SENSOR circuit on a colored filter substrate of the ON CELL TFT liquid crystal display, bonding a TFT FPC on the TFT substrate under the ON CELL TFT liquid crystal display, pasting an upper polaroid and a lower polaroid, pasting solid-state OCA optical cement on the upper polaroid of the prepared ON CELL TFT liquid crystal display, performing full lamination on the upper polaroid and cover plate glass, and finally, assembling backlight with the full lamination upper polaroid and cover plate glass to form an ON CELL solid-state full lamination module. The processing method has the following advantages: the prepared ON CELL solid-state full lamination module has the advantages of simple processing flow, high assembling accuracy and processing yield.

Owner:JIANGXI HOLITECH TECH

Manufacturing and processing method for direct-bonding TFT LCM

InactiveCN104181712ASimplify the machining processImprove alignment accuracyLaminationLamination apparatusPolarizerLiquid crystal

The invention provides a manufacturing and processing method for a direct-bonding TFT LCM (Liquid Crystal Module), and belongs to the technical field of direct-bonding module processing. The realization process of the manufacturing and processing method is as follows: not assembling backlight on TFT LCM in a direct-bonding module, and gluing OCA on the surface of an up polarizer of FOG in the TFT LCM; after pre-baking and pressurizing for defoaming, using a jig to carry out aligned pre-gluing processing on CTP and FOG; adopting a gluing machine for pressing operation; reusing the jig to assemble backlight after warming and pressurizing for defoaming through a defoaming furnace. The manufacturing and processing method has the advantages that direct-bonding products processed by adopting the method has the advantages of being simple in processing process, high in alignment precision, less in foams in product gluing, high in yield and the like.

Owner:JIANGXI HOLITECH TECH

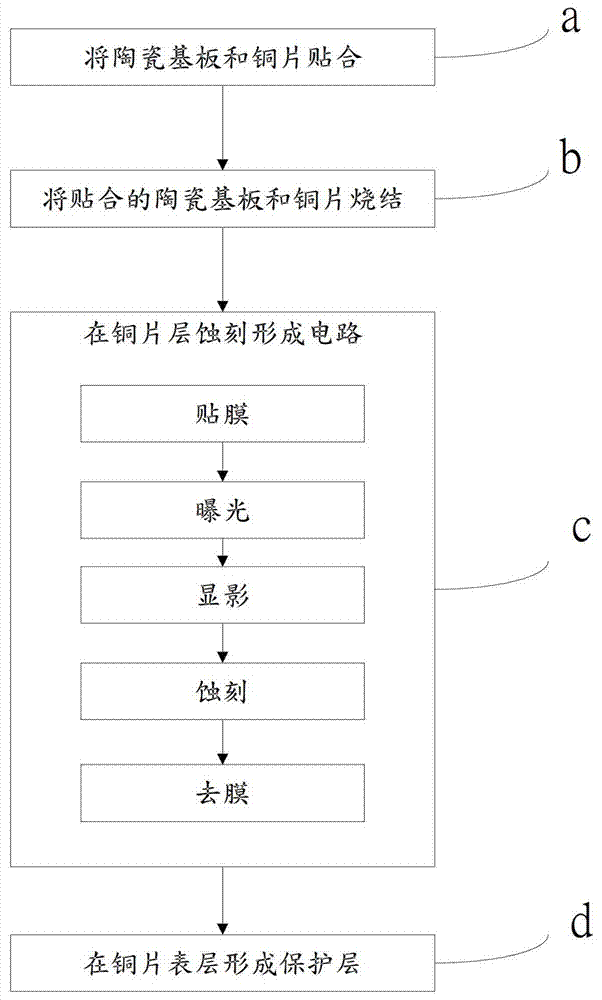

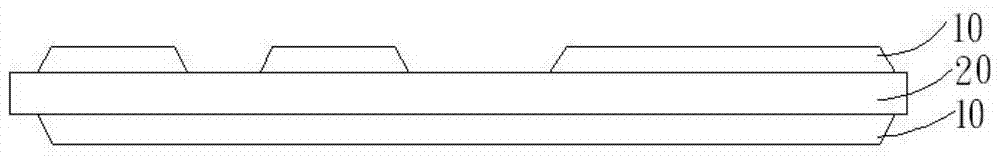

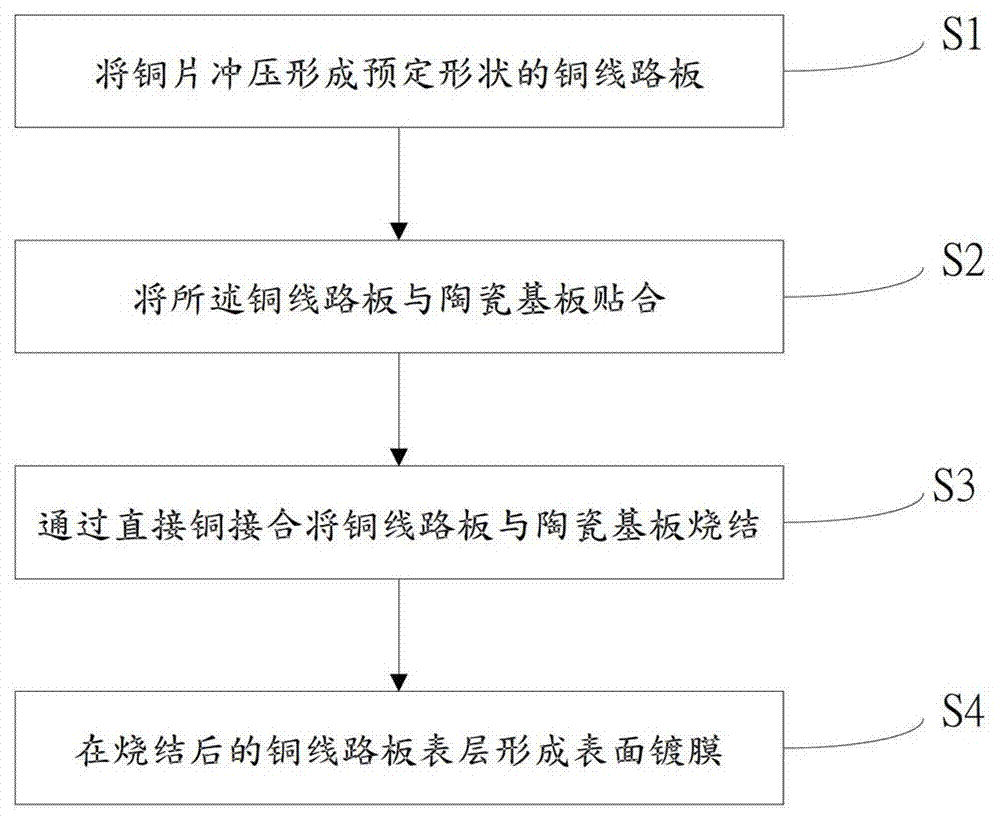

Copper-clad ceramic substrate manufacturing method

InactiveCN107295755ASimplify the machining processReduce typesPrinted circuit manufactureEtchingMetallurgy

The invention discloses a copper-clad ceramic substrate manufacturing method. The method comprises steps: a copper sheet is stamped to form a copper circuit board in a predetermined shape; the copper circuit board and the ceramic substrate are attached; and through direct copper joint, the copper circuit board and the ceramic substrate are sintered. According to the copper-clad ceramic substrate manufacturing method disclosed in the invention, the processing process is simplified, steps such as film mounting, exposure, development, etching and film removal in the existing processing process are cancelled, needed materials and device kinds are reduced, and the economical efficiency is improved; stamping to form the copper circuit board is used to replace the etching process, copper material recovery and utilization are facilitated, the pressure of wastewater treatment is reduced, and the method is environment-friendly; and besides, the copper circuit board formed through stamping is good in circuit perpendicularity, and the isolation performance is good.

Owner:SHUNSIN TECH (ZHONG SHAN) LTD

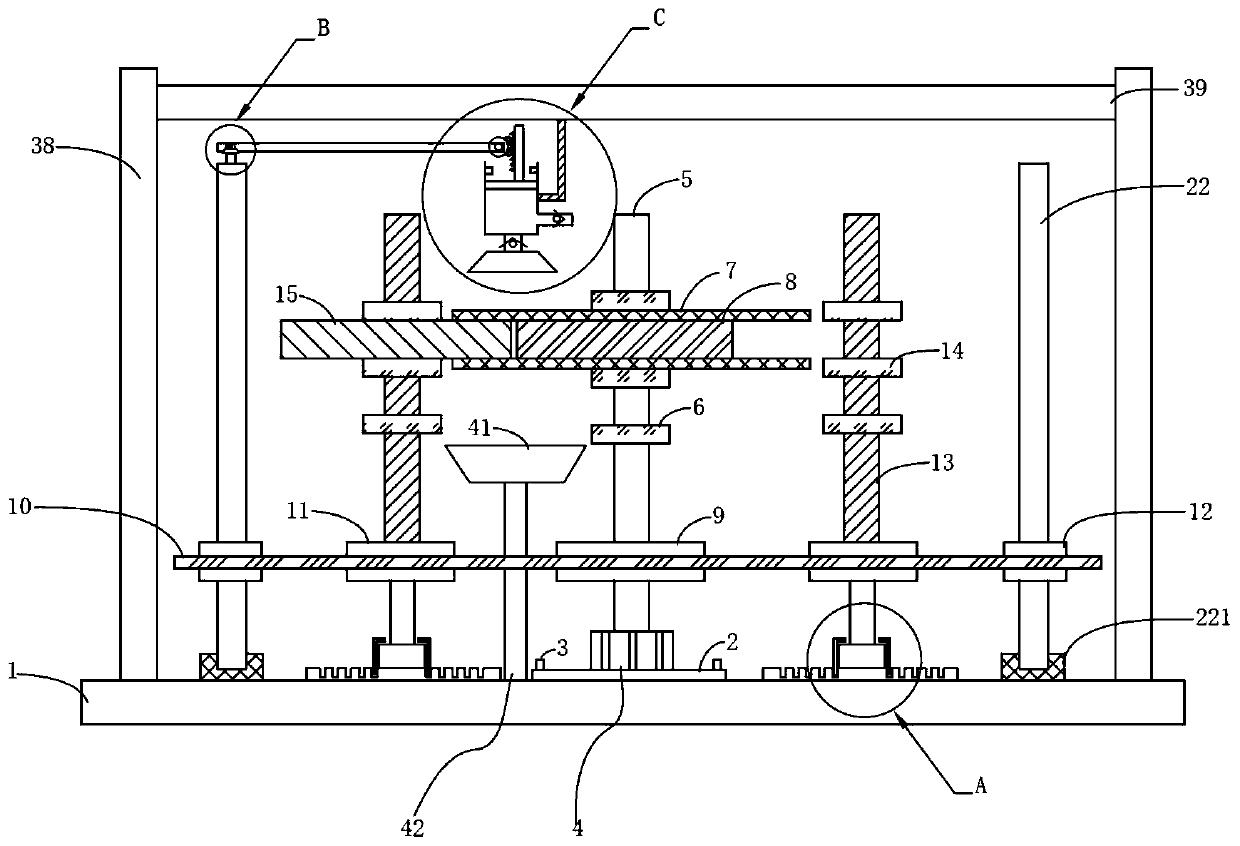

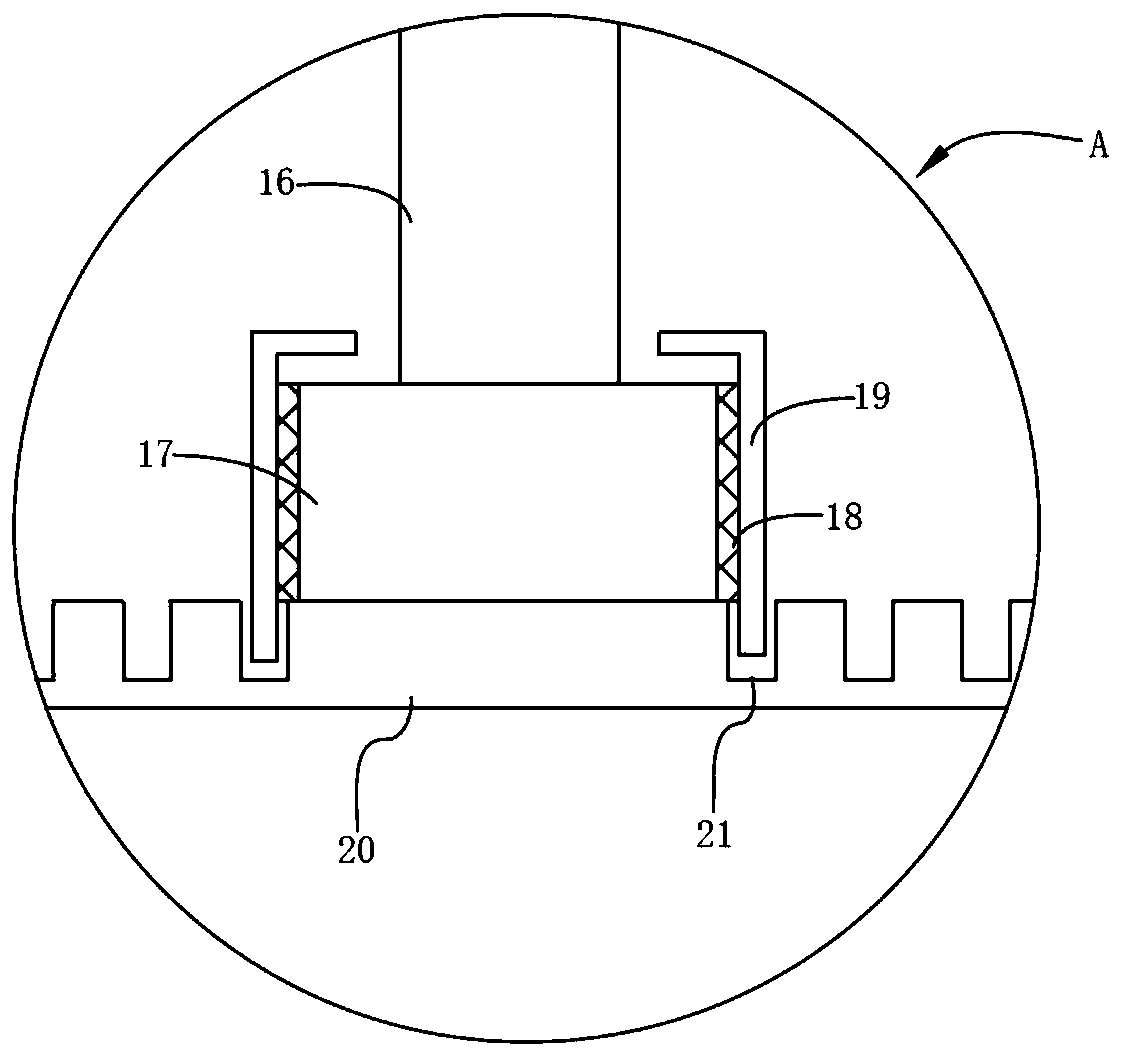

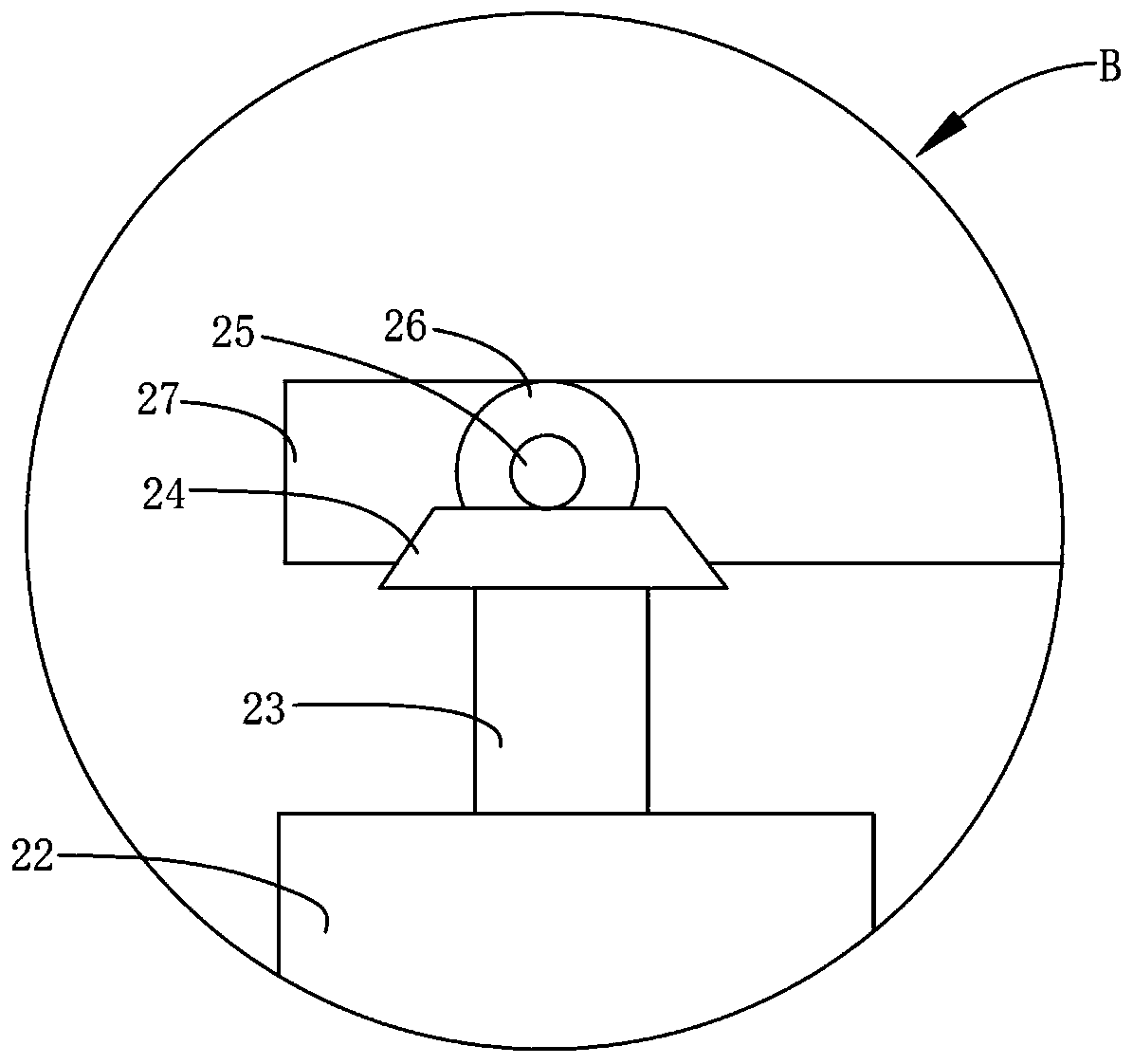

Running-in device of gear

InactiveCN110125761ASave time at workSimplify the machining processSeat surface grinding machinesPistonEngineering

The invention discloses a running-in device of a gear. The device comprises a base, a sliding plate is fixedly arranged on the base, multiple adjusting nuts are arranged on a center thread rod in a threaded manner, a running-in wheel is arranged between adjacent running-in plates in a threaded manner, a gear to be subjected to running in is arranged between adjacent positioning nuts in a threadedmanner, a second transmission wheel is fixedly connected to the center of an incomplete gear through a connecting shaft, the incomplete gear and a rack are movably engaged, a pushing plate is movablyarranged in a piston, the piston is provided with an air outlet pipe and an air inlet pipe in a communication manner, and one-way valves are arranged in the air outlet pipe and the air inlet pipe. According to the running-in device of the gear, the device can adapt to multiple specifications of gears, the multiple gears can be subjected to running-in at the same time, the gear face and two planesof the gears can be subjected to running in at the same time, the efficiency is higher, a device capable of blowing off and collecting abrasive dust is internally arranged, and the machining of the running-in gear can be effectively improved.

Owner:BENGBU COLLEGE

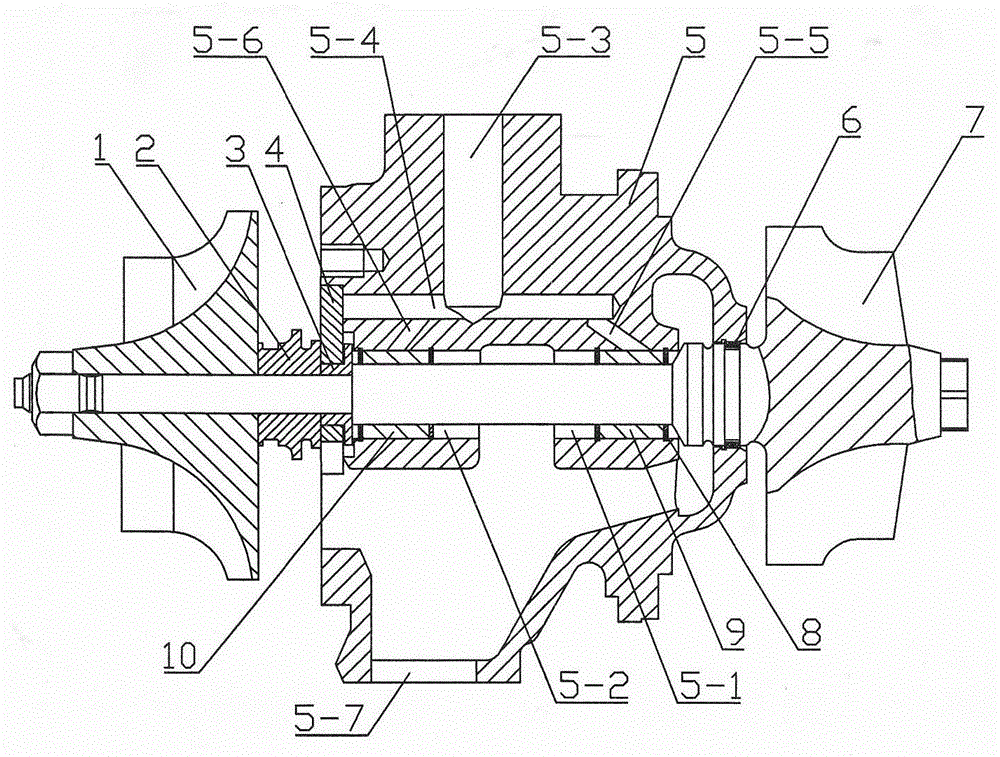

Full-floating bearing turbocharger rotor system

ActiveCN104989461ASimplify the machining processOptimize componentsShaftsBlade accessoriesImpellerEngineering

The invention discloses a full-floating bearing turbocharger rotor system. A turbine end full-floating bearing is mounted in a turbine end full-floating bearing mounting hole ina bearing body; a first anti-thrust end surface of the turbine end full-floating bearing makes contact with the bottom end surface of the turbine end full-floating bearing mounting hole; a pressure air end full-floating bearing is mounted in a pressure air end full-floating bearing mounting hole inthe bearing body; a second anti-thrust end surface of the pressure air end full-floating bearing makes contact with the bottom end surface of the pressure air end full-floating bearing mounting hole; a turbine rotor shaft is mounted in a bearing hole of the turbine end full-floating bearing and a bearing hole of the pressure air end full-floating bearing; a pressure air end sealing sleeve and an impeller are mounted at the other end of a shaft rod of the turbine rotor shaftin sequence, and are fixed on the shaft rod of the turbine rotor shaft through nuts; and a sealing ring is mounted in an annular sealing groove on the shaft rod of the turbine rotor shaft for sealing the turbine end of the bearing body. The shaft rod of the turbine rotor shaft and the inner wall of the first shaft rod hole form a first oil discharge cavity A, and the shaft rod of the turbine rotor shaft and the inner wall of the second shaft rod hole form a second oil discharge cavity B.

Owner:HUNAN TYEN MACHINERY

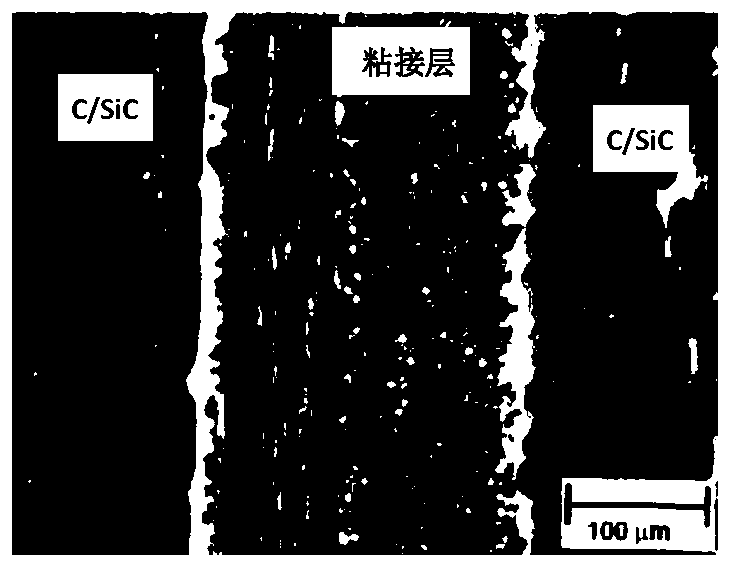

Preparation method of carbon-ceramic brake disc

ActiveCN110483086AIncrease profitSimplify the machining processFriction liningMaterials processingFiber

The invention relates to a preparation method of a carbon-ceramic brake disc. The preparation method comprises the following specific steps: preparing a carbon fiber preform; carrying out chemical vapor deposition on the preform to prepare a C / C composite material; processing the C / C composite material into unit modules; bonding to prepare a C / C brake disc; and preparing the carbon-ceramic brake disc through reactive melt permeation. By means of the method, the material utilization rate can be increased, waste and loss of materials for machining the carbon / ceramic brake disc are avoided, the machining time is shortened, and therefore the production cost of the carbon / ceramic brake disc is greatly reduced.

Owner:山东道普安制动材料有限公司

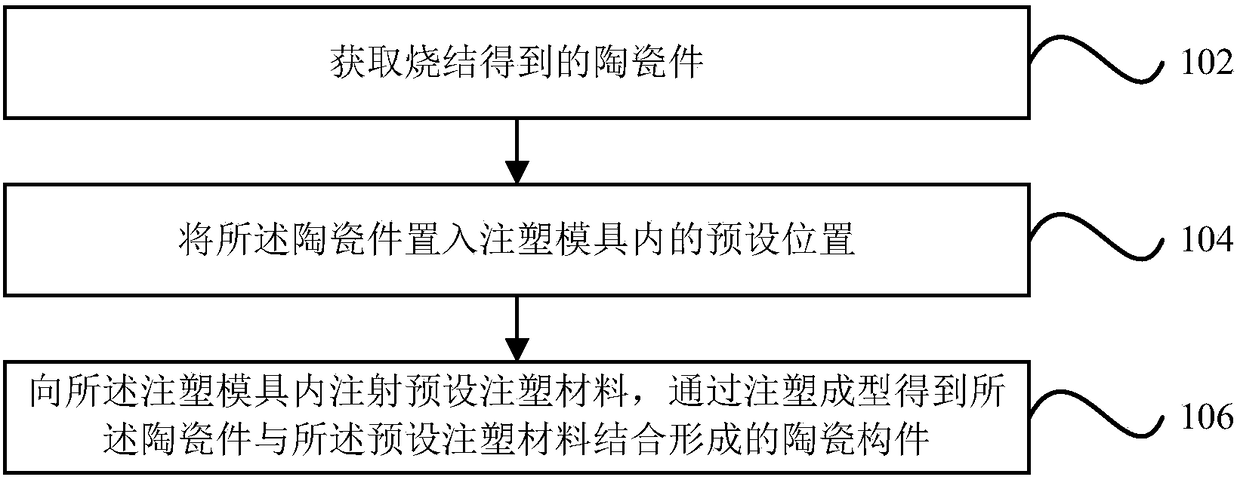

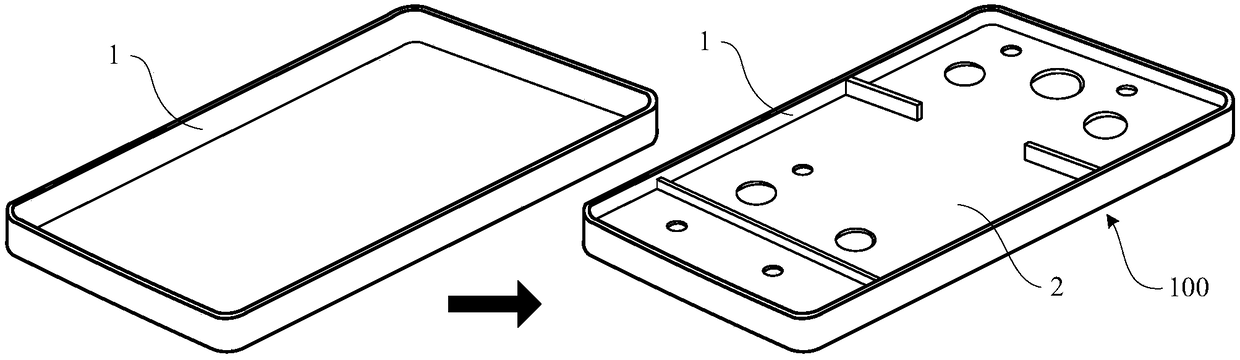

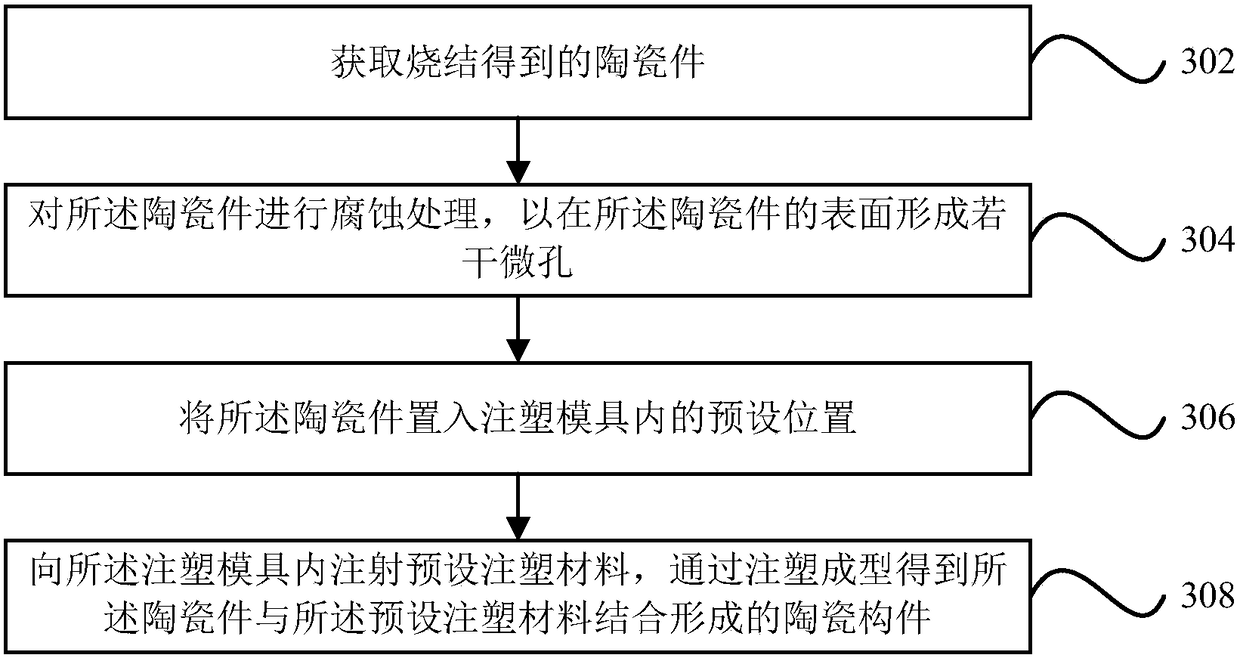

Ceramic component and molding process thereof, and electronic equipment

ActiveCN108202440ASimplify the machining processImprove processing efficiencyRack/frame constructionElectrical apparatus casings/cabinets/drawersComposite materialInjection moulding

The invention relates to a ceramic component and a molding process thereof, and electronic equipment. The molding process includes the steps that a ceramic part is obtained through sintering; the ceramic part is placed into a preset position in an injection mold; and preset injection molding materials are injected into the injection mold, and the ceramic component formed by combining the ceramic part and the preset injection molding materials is obtained through injection molding. Through the technical scheme of the invention, the processing process of the ceramic component can be simplified,production efficiency can be improved, processing precision can be improved, and the yield of the ceramic component is increased advantageously.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

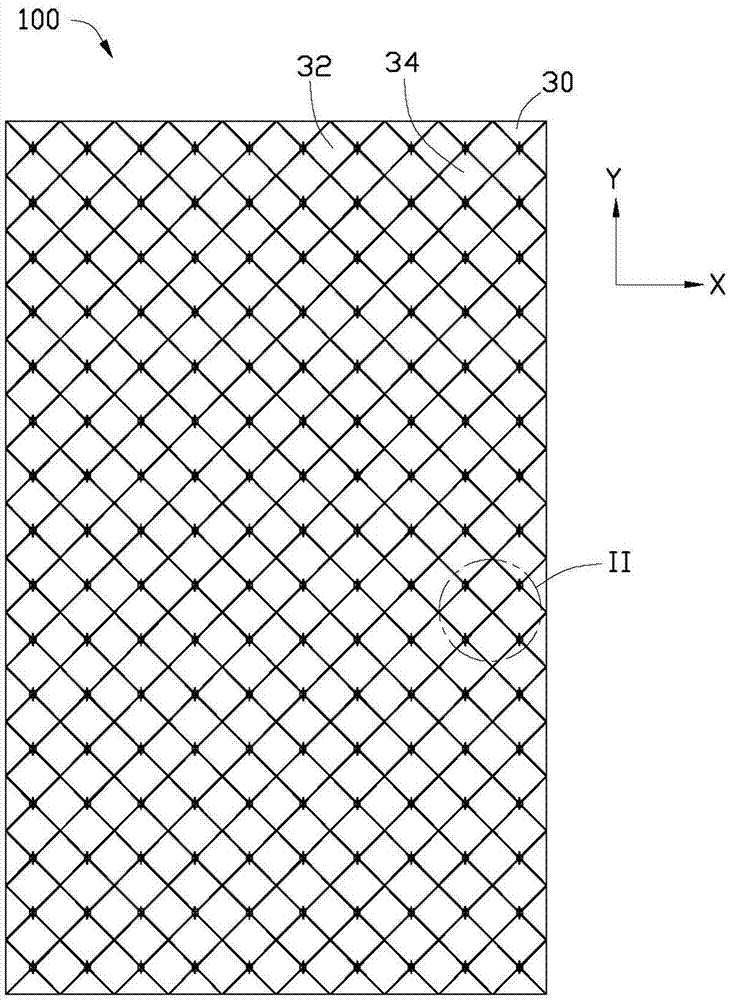

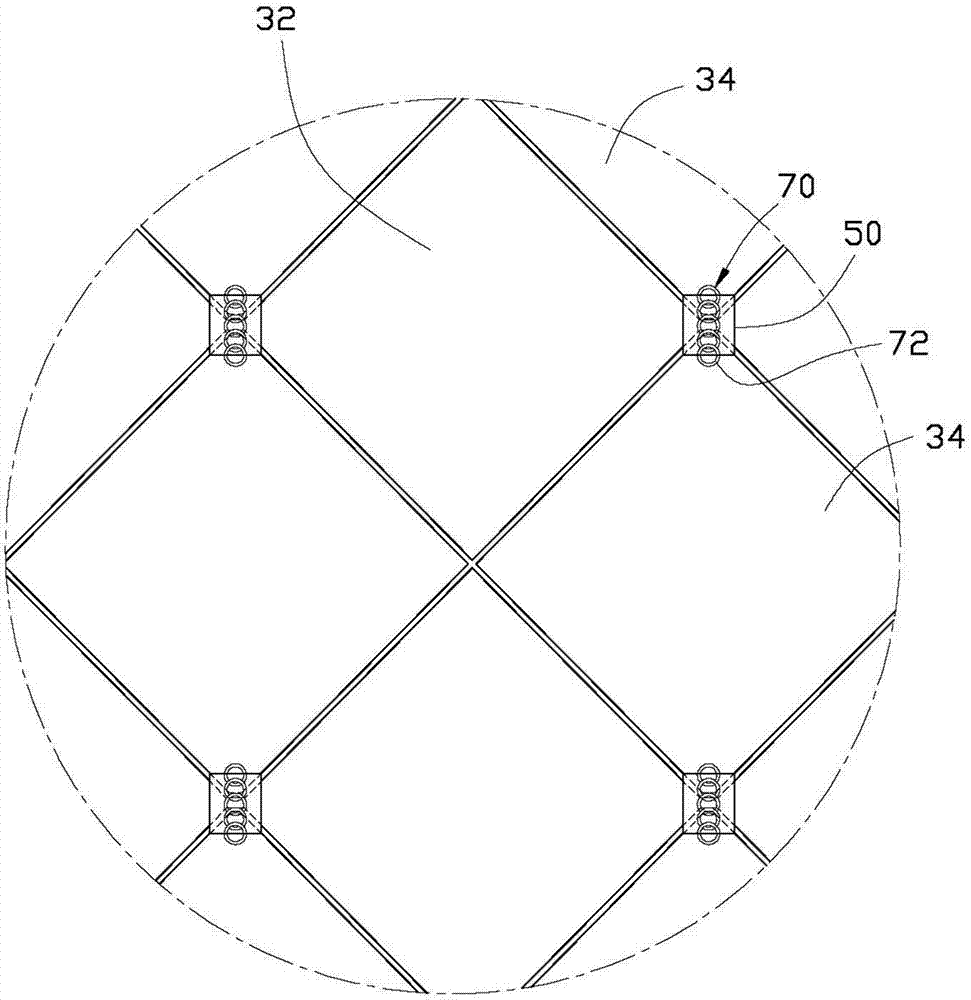

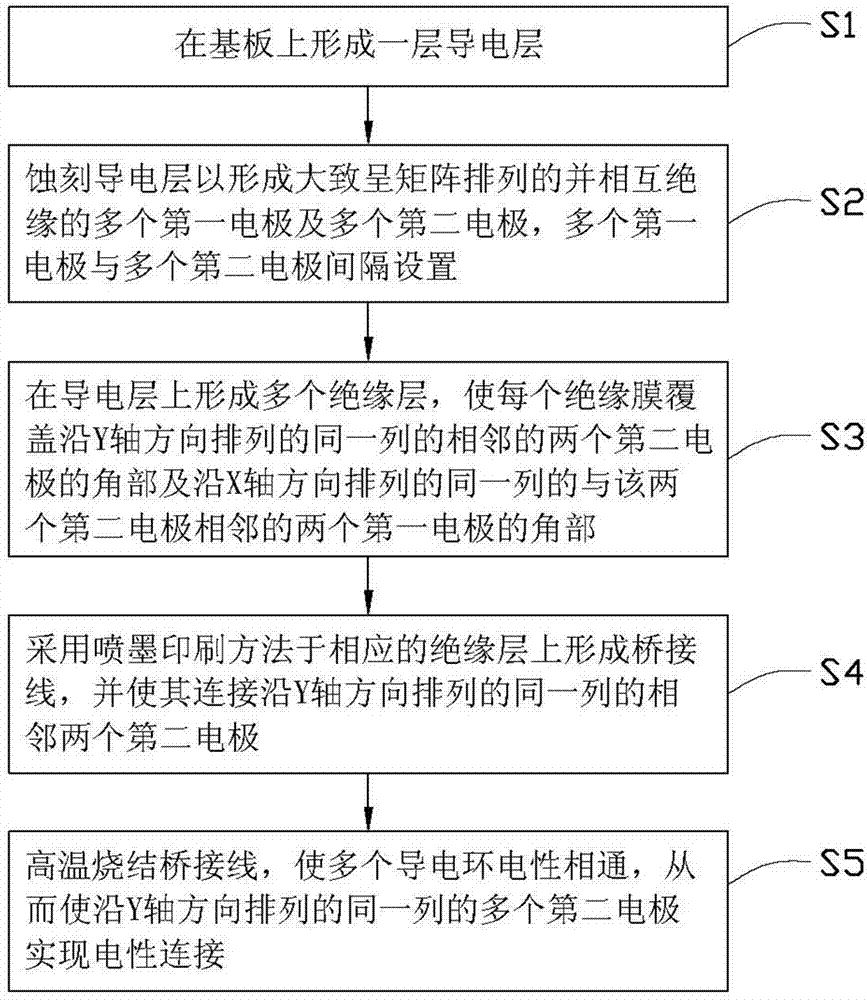

Touch screen and manufacture method thereof

InactiveCN104750283ASimplify the machining processImprove processing efficiencyInput/output processes for data processingEngineeringElectrical and Electronics engineering

The invention discloses a manufacture method of a touch screen. The manufacture method comprises the following steps: forming a conducting layer on a substrate; etching the conducting layer to form a plurality of first electrodes and a plurality of second electrodes, wherein the first electrodes and the second electrodes are roughly arranged in a matrix way, are mutually insulated and are arranged at intervals; forming a plurality of insulating layers on the conducting layer, wherein each insulating layer covers the corners of two adjacent first electrodes arranged in the same row arranged along a first direction and the corners of two adjacent second electrodes arranged in the same line arranged in a second direction; and adopting an ink jet printing method to form a plurality of conducting rings which are mutually connected in series on the corresponding insulating layer. The invention also provides the touch screen which adopts the manufacture method. The manufacture method has the advantages of being simple in manufacture procedures and high in processing efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Contact type connected electronic equipment

InactiveCN107994363ASimplify the machining processSimplify the assembly processTelephony connectorsFixed connectionsPogo pinBiomedical engineering

The invention discloses contact type connected electronic equipment. The contact type connected electronic equipment comprises a circuit board, a circuit board support, a POGO PIN, a POGO PIN support,a patch spring plate and a PCB, wherein the FPC is arranged on one side of the FPC support, and a through hole corresponding to the size of the POGO PIN is formed in the POGO PIN support; a groove isformed in the POGO PIN support, the groove communicates with the through hole, and the groove is internally provided with the patch spring plate; the POGO PIN is of a solid structure; the patch spring plate comprises an electric component and a base, and the elastic component is connected with the base; one end of the POGO PIN passing through the corresponding through hole is connected with the FPC, and the other end of the POGO PIN is connected to the elastic component of the elastic component; and the base of the patch elastic plate is fixedly connected with the PCB. According to the contact type connected electronic equipment provided by the invention, by adopting the solid type POGO PIN, the processing is simple, the post processing is simple, and the cost is low; by adopting the combined structure of the solid POGO PIN and the patch spring plate, the equipment is convenient to dismount and mount and is of more flexibility for later period; the equipment can be applicable for various structures of electronic equipment; and moreover, the equipment is low in impedance and good in circuit conduction performance, and the impedance performance is promoted by 50%.

Owner:WINGTECH COMM

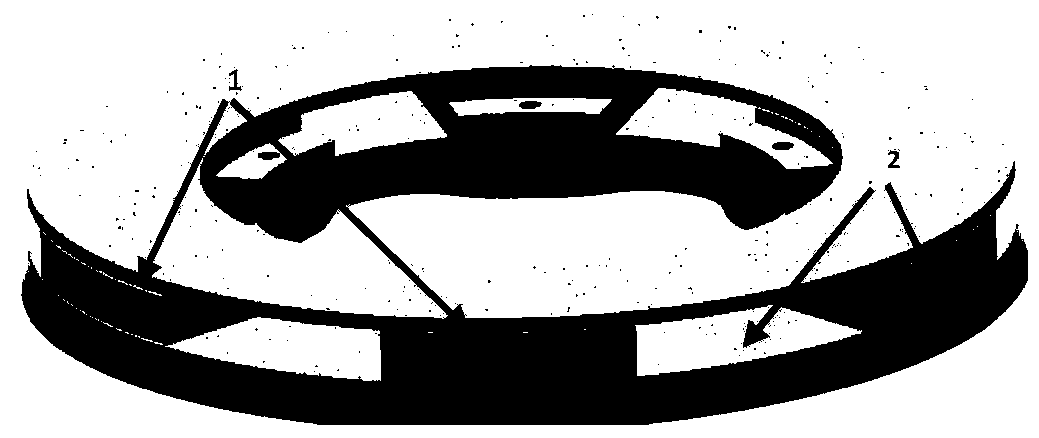

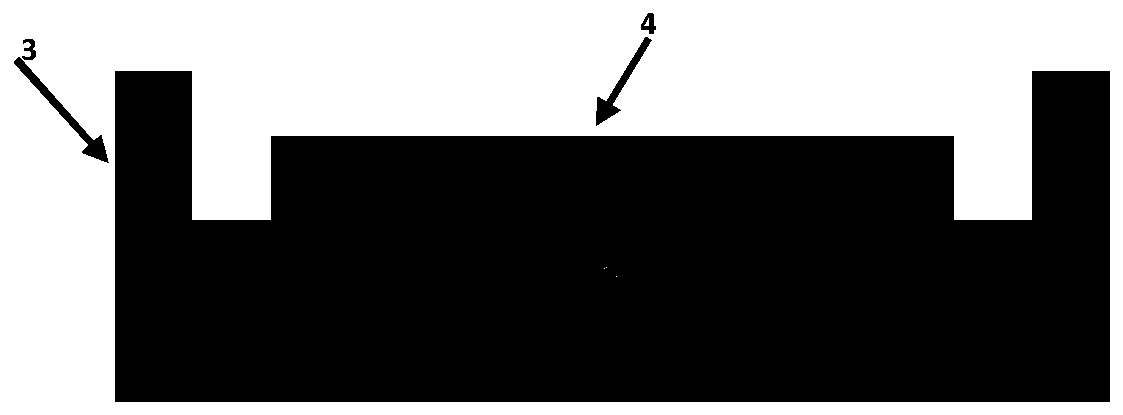

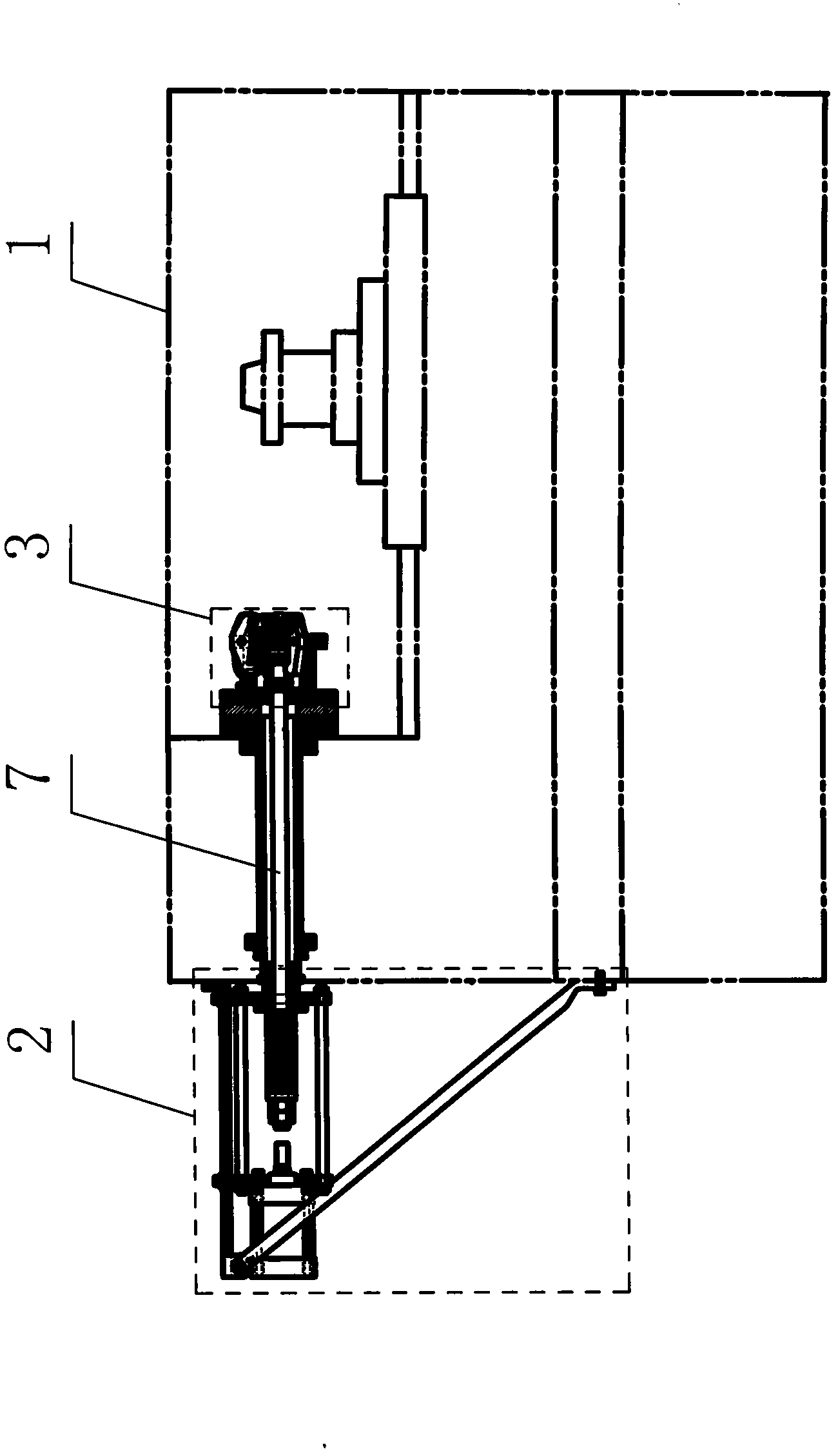

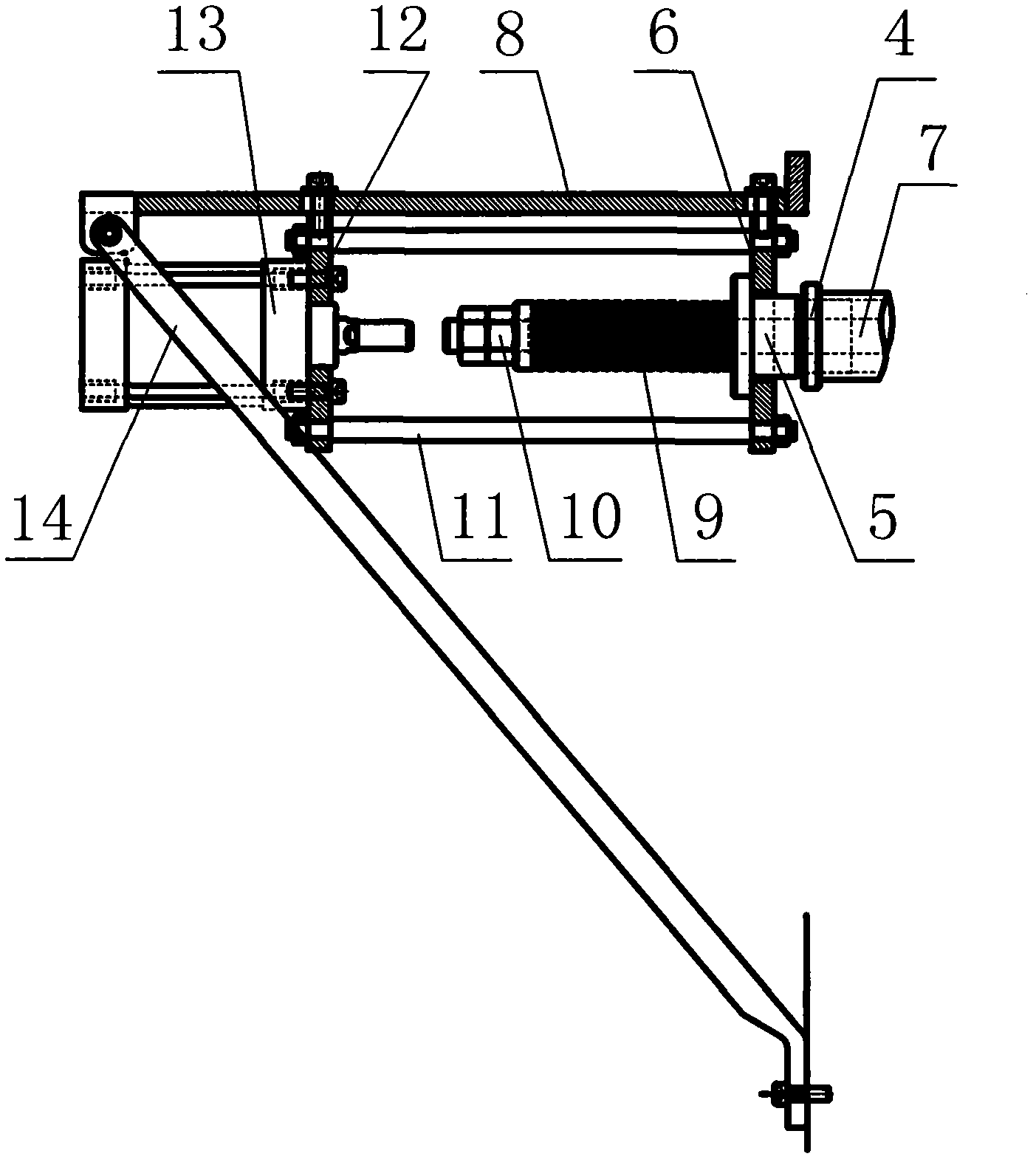

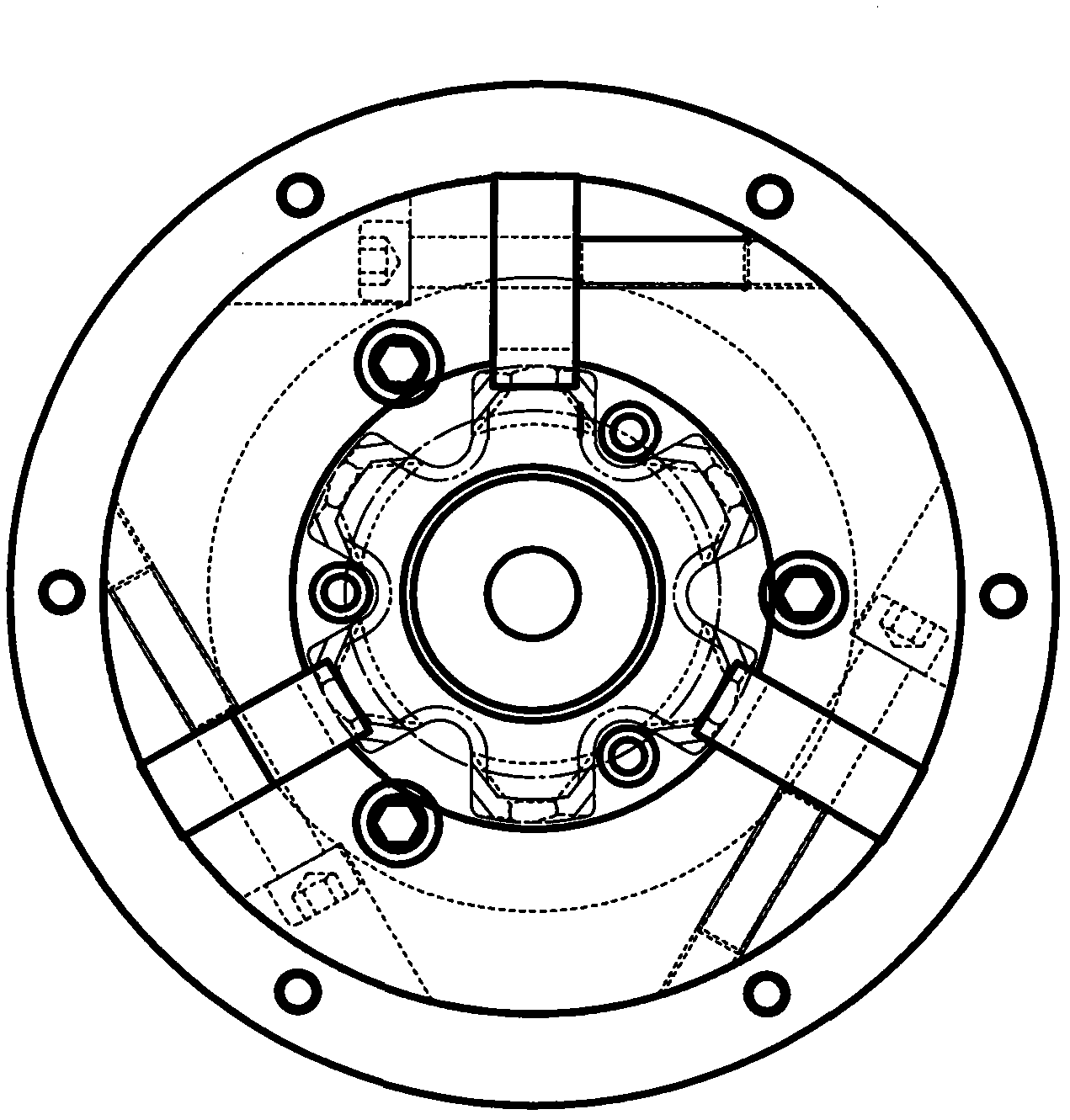

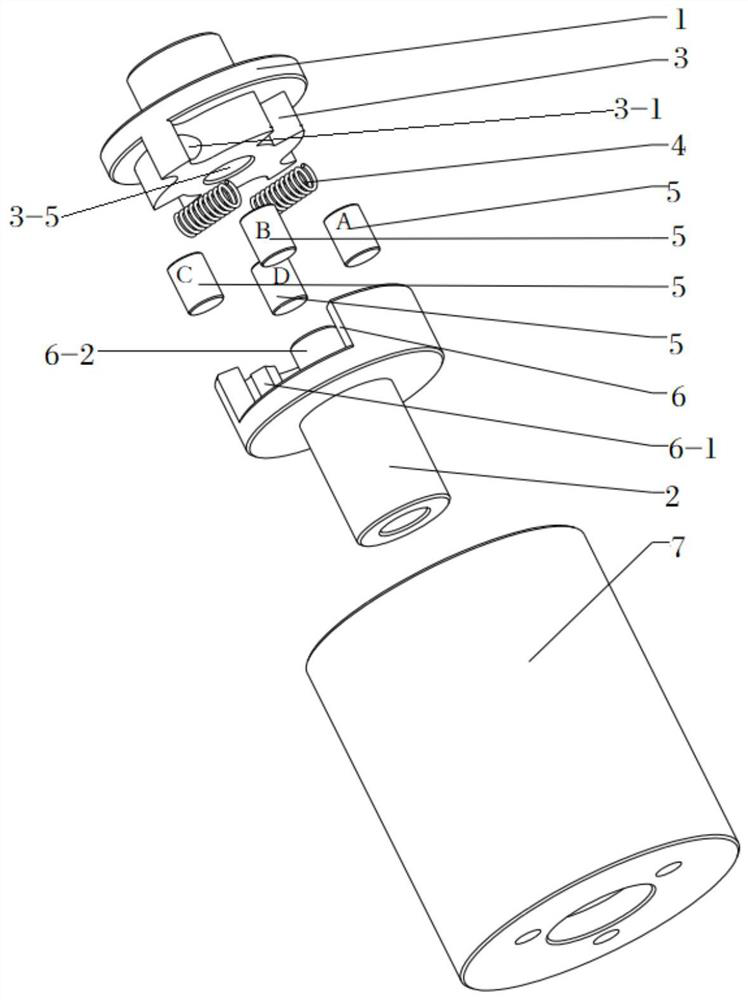

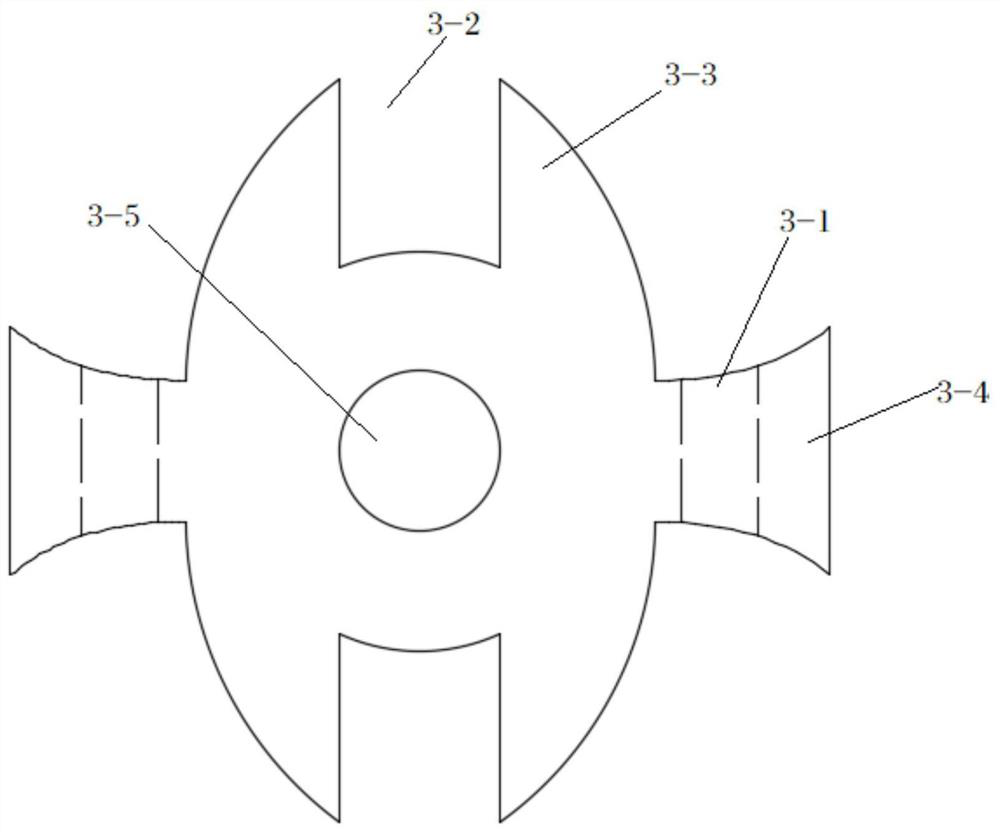

Pneumatic clamp for processing of claw pole outer surface

The invention relates to a pneumatic clamp for the processing of the claw pole outer surface and belongs to the technical field of claw pole accessories processing. The pneumatic clamp comprises a pneumatic device and a self-balancing three jaw chuck which are coupled with each other through a pull rod; the pneumatic device comrises a coupling head, a front pull plate, a pull rod, a cross plate, a disk spring, a coupling rod, an air cylinder coupling plate and an air cylinder; the self-balancing three jaw chuck comprises a flange plate, a spring pressure plate, a locking tip cone, a locking jaw, a cover plate, a positioning core shaft, and a cylinder. According to the invention, the pneumatic clamp is positioned through the claw pole inner surface, centered through a central hole and clamped through a self-balancing three jaw; operator labor intensity and requirements for operator skills are reduced, and processing efficiency and equipment utilization rate are increased; and the problems as follows are solved: in the prior art that the processing of the claw pole outer surface is carried out through an engine lathe, thus the labor intensity is great, sand holes, air holes and surface accumulated burl of a claw pole blank easily cause a lathe tool to have edge breaking, the tool needs to be polished and adjusted repeatedly, the processing is time-consuming and labor-consuming, and the production efficiency and the product quality are influenced.

Owner:荆州市万寿汽车零部件有限公司

Processing method of sound hole of MEMS carrier plate

InactiveCN111542170ASimplify the machining processReduce processing costsDecorative surface effectsPrinted circuit manufactureEngineeringMechanical engineering

The invention discloses a processing method of a sound hole of an MEMS carrier plate. The method comprises the following steps: preparing an MEMS carrier plate, wherein the MEMS carrier plate comprises a core plate formed by laminating and compounding two inner copper layers and an inner insulating layer, two first copper layers laminated on the surfaces of the two inner copper layers through a first insulating layer respectively, and two second copper layers laminated on the surfaces of the two first copper layers through a second insulating layer respectively; performing laser windowing on the second copper layers to form a window capable of exposing a local surface of the second insulating layer; performing laser ablation grooving on the exposed surface area of each second insulating layer, and processing a blind groove capable of penetrating through the second insulating layer and the first insulating layer; and carrying out laser hole cutting on the MEMS carrier plate and at the position corresponding to the bottom of the blind groove, and processing a sound hole with one end communicated with the blind groove and the other end penetrating through the other second copper layer. The sound hole processing method has the advantages of being simple, easy to operate, high in operation precision, high in machining efficiency and the like, and the sound hole quality is guaranteed.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

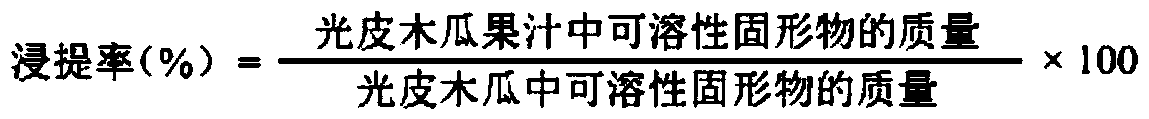

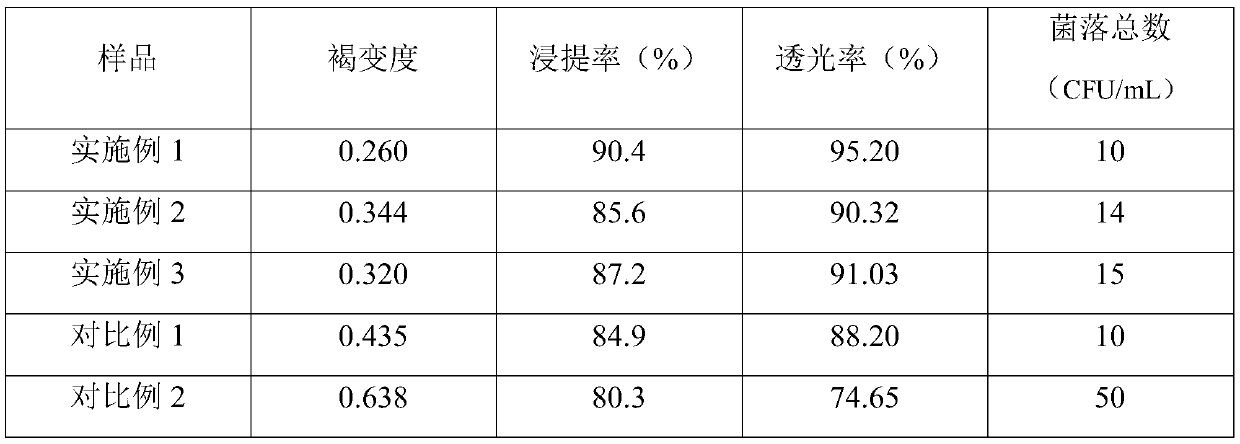

Processing method of chaenomeles sinensis koehne clear juice

PendingCN110074294AImprove light transmittance and stabilitySimplify the machining processFood ingredient as taste affecting agentUltrafiltrationSocial significance

The invention discloses a processing method of chaenomeles sinensis koehne clear juice. The method comprises the following steps: crushing chaenomeles sinensis koehne and adding a composite color fixative in a crushing process; mixing crushed chaenomeles sinensis koehne with deionized water to obtain mixed slurry, and adding cellulose complex enzyme and pectinase into the mixed slurry for enzymolysis extraction; performing enzyme deactivation after enzymolysis, cooling, filtering and collecting filtrate to obtain chaenomeles sinensis koehne primary juice; adding a clarifying agent into the chaenomeles sinensis koehne primary juice, uniformly stirring, then standing and performing ultrafiltration to obtain clear juice; filling the clear juice into flexible packages to perform high hydrostatic pressure sterilization treatment to obtain a clear juice product. According to the processing method of the chaenomeles sinensis koehne clear juice, by aiming at the problems existing during processing of the chaenomeles sinensis koehne clear juice, four key process steps of juice color protection, enzymolysis extraction, juice clarification and finished product sterilization are optimized andimproved, the purposes of improving the extraction rate, removing astringency, and reducing browning and loss of nutritional ingredients are achieved, no separate deastringent process is needed, and important economic and social significance in promoting the development of chaenomeles sinensis koehne industry is realized.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

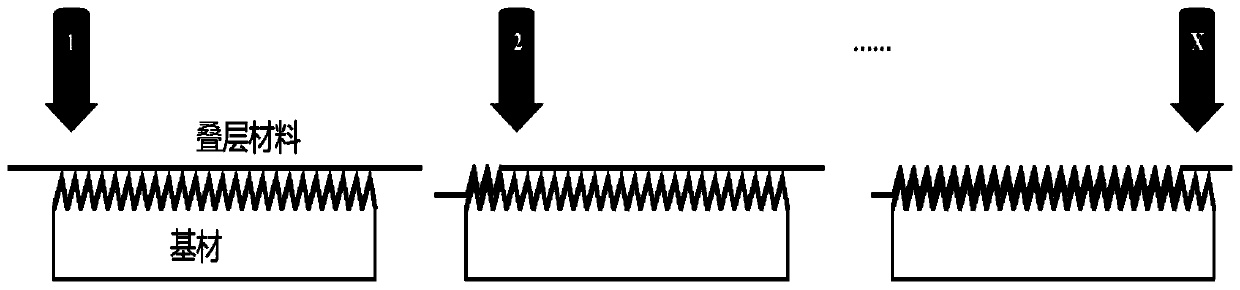

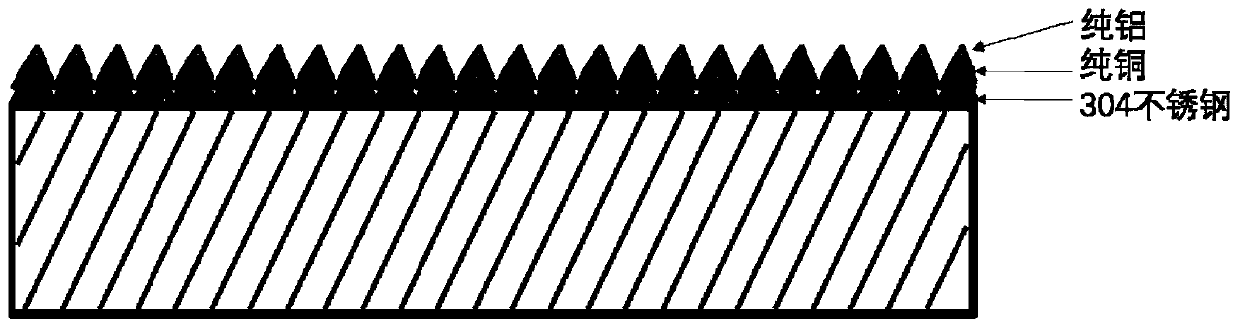

Method for forming laminated composite material by laser impact and application of method

ActiveCN110560887AHigh lamination bonding strengthSimplify the machining processLaser beam welding apparatusRough surfaceBonding strength

The invention relates to the technical field of metal laminated composite materials, in particular to a method for forming a laminated composite material by laser impact and application of the method.The method comprises the following steps: preparing a rough surface with high surface roughness on a base material surface, and cleaning the rough surface for later use; improving surface smoothnessof the laminated material, and cleaning the laminated material for later use; preparing an absorbing layer and a restraint layer material on a surface, which is not in contact with a base material, ofthe to-be-laminated material for later use; adopting a laser impact method to clamp the surface of the base material and process an area which covers the laminated material; clearing the rest of theabsorbing layer and the restraint layer material after performing laser impact processing on all of the laminated material covering area, and cleaning the laminated composite material to obtain the laminated composite material. The invention discloses the method for forming the laminated composite material by laser impact based on pulse impact-induced force effect, and the method has the advantages of being high in laminated layer bonding strength, and the like; and moreover, the method is simple in processing process, and is more energy-saving and efficient compared with a conventional method.

Owner:SHANDONG UNIV

Through hole filling fusion HDI processing technology

ActiveCN111278237AEasy placementSimplify the machining processMultilayer circuit manufacturePrinted element electric connection formationPhysicsEngineering

The invention discloses a through hole filling fusion HDI processing process, and relates to the technical field of computer hardware equipment. According to the process, a hole is drilled in a PCB, and a copper base used for heat dissipation is embedded into the PCB in an electroplating hole filling mode. The embedded copper fusion HDI technology is adopted, the surface of the position, where thecomponent needs to be mounted, of the PCB is smooth, and the problems that in the embedded technology, the height difference exists between the surface of the copper block and the surface of the PCB,the concave problem exists in the joint position of the copper block and the PCB, and when the electronic component is mounted, poor placement of the component is likely to happen are solved. Besides, the process adopts an embedded copper fusion HDI technology, the processing flow is simple, the problems of delamination, cracks and the like caused by the fact that recesses exist at the connectionpositions of the copper blocks and the PCB after metal base lamination and no base material copper exists at the connection positions of the copper blocks and the PCB in an embedded metal base technology are avoided, and HDI products with two or more orders can be processed.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Silicon resin and preparing method thereof

The invention discloses a silicon resin and a method for manufacturing the same. The silicon resin is invented for solving the problems in the prior art, such as high manufacturing cost and so on. The materials by weight portion of the silicon resin are: 100 portions of 107 adhesive or vinyl silicone oil, 0.5 to 5 portions of cross linker, 0.1 to 1 portion of inhibitor, 0.1 to 5 portions of firming agent, 0 to 50 portions of liquid silicone rubber, and 0 to 50 portions of white carbon black. The method for manufacturing the silicon resin comprises the following steps of: using 100 portions of the 107 adhesive or the vinyl silicone oil; adding 0 to 50 portions of the liquid silicone rubber to stir evenly; adding 0 to 50 portions of the white silicone rubber to stir until the white silicone rubber is absorbed completely; adding 0.5 to 5 portions of containing hydrogen silicone oil to stir evenly for about 30 minutes; adding 0.1 to 1 portion of the inhibitor to stir evenly; and adding 0.1 to 5 portions of firming agent to stir evenly before manufacturing. The silicon resin manufactured by the materials and the method uses materials with low cost, simplifies the whole processing flow, improves the production efficiency, improves the production quality, and reduces environmental pollution.

Owner:杨金海

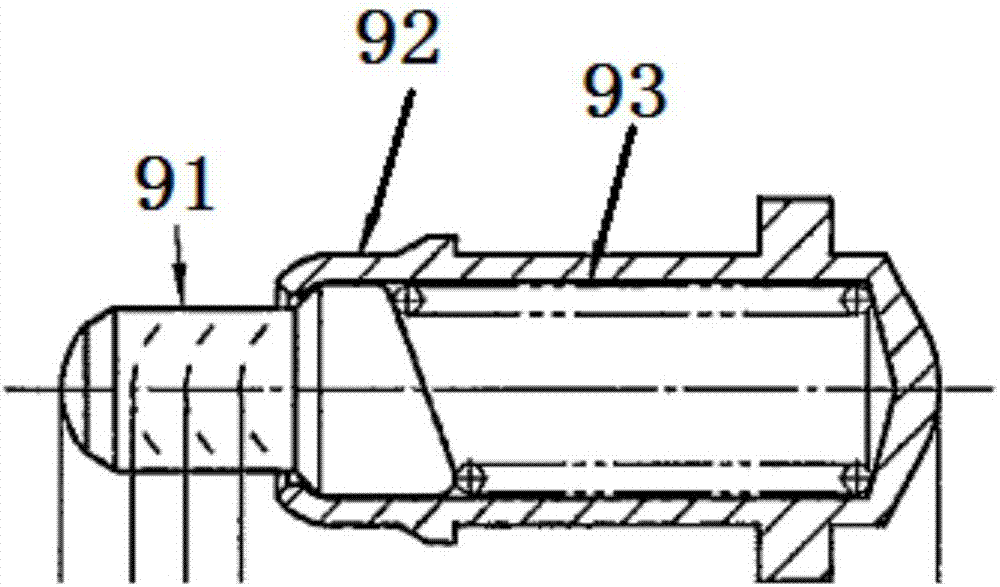

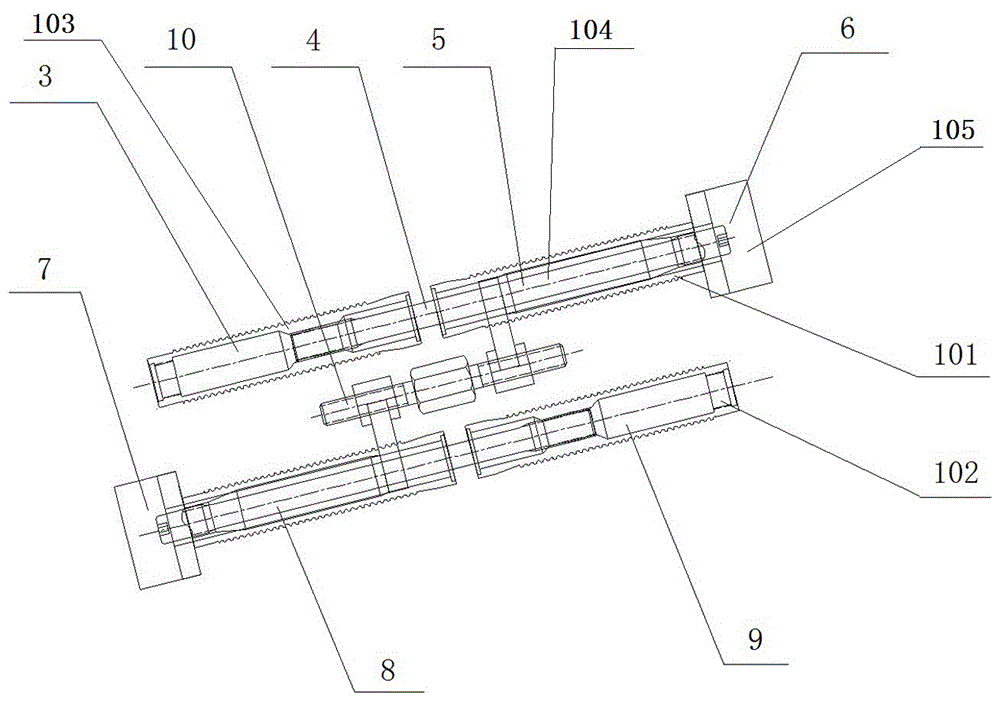

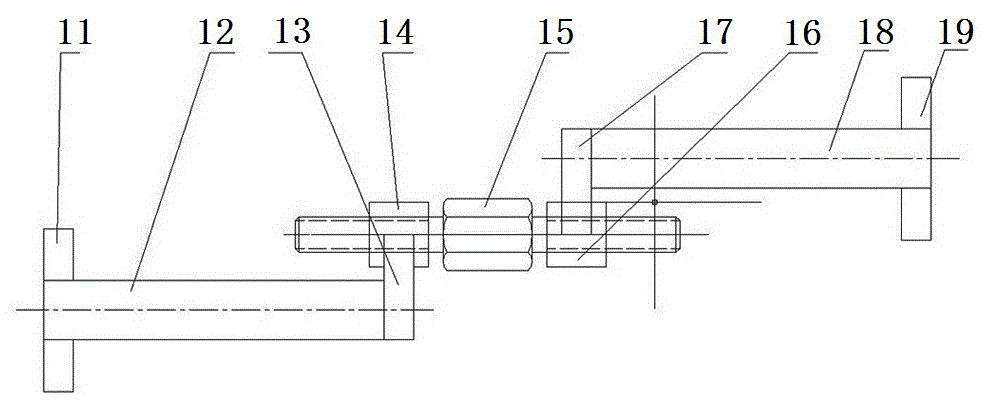

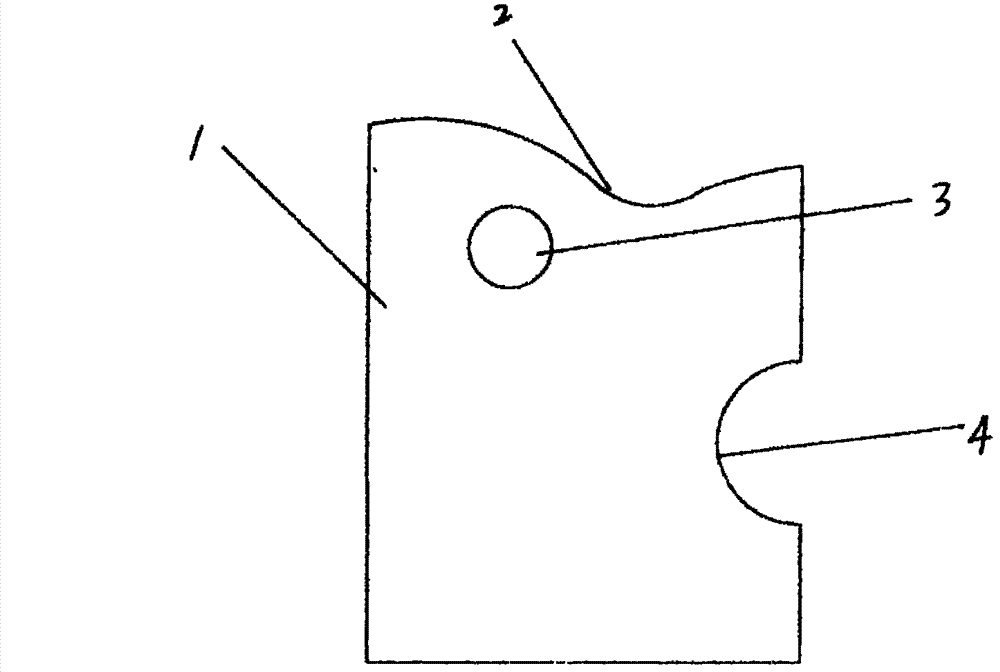

Wind power blade connecting device

ActiveCN105863956AAvoid weight gainCompact structureMachines/enginesWind energy generationElectricityMachining process

The invention aims at providing a wind power blade connecting device to solve the problems that in the prior art, a connector device and a long bolt sleeve are arranged, and consequently, the dead load of a segmented blade is increased, the axial rigidity of the bolt is reduced, connecting load coefficients and borne fatigue loads are increased, and the fatigue life of the bolt is shortened. At least two sets of devices are arranged, and every two adjacent sets of the devices are arranged in the forward direction and the reverse direction correspondingly and are connected through a wall pulley. A bolt assembly of the connecting device is used for connecting a blade root section of the segmented blade and a blade tip section of the segmented blade. One end of the bolt assembly is connected with a bolt sleeve, and the other end of the bolt assembly is connected with a polished sleeve. The tail end of the polished sleeve is provided with a wrench space. Due to the design of an embedded block of the wind power blade connecting device, the connecting structure is optimized, the machining processes are simplified, the fixing manner is firm and reliable, and the problems existing the prior art are effectively solved.

Owner:BAIYIN SINO WIND ENERGY

Method for preparing piezoelectric ceramic blank film

InactiveCN101265110ASimplify the machining processLow manufacturing costCeramic shaping apparatusGlycerolPlastic film

The invention discloses a method for producing piezoelectric ceramic membrane. The method comprises the following steps: adding a binder in piezoelectric ceramic powder, rough rolling, fine rolling and punching. The method is characterized in that: the additional amount of the binder is 15-25% the weight of the piezoelectric ceramic powder, the powder containing the binder is stirred and rolled for 4-8 hours at 20-30 DEG C to produce rough-rolled blank belt, the blank belt is sliced and wrapped with plastic film and then is subject to fine rolling for 1-2 hours at 20-30 DEG C to produce a fine-rolled blank belt, the fine-rolled blank belt is wrapped with plastic film and then punched to produce the piezoelectric ceramic membrane; and the binder is composed of the following components in weight percentages: polyvinyl alcohol 5-20%, glycerol 3-10%, ethanol 0-10% and distilled water in balance. The method is simple and has low cost. The piezoelectric ceramic membrane has ultrathin thickness (0.05-0.1 mm) and high density; and is widely used for piezoelectric ceramic electro-acoustic transducers and other thin piezoelectric products.

Owner:JIANGSU YUCHENG ELECTRONICS

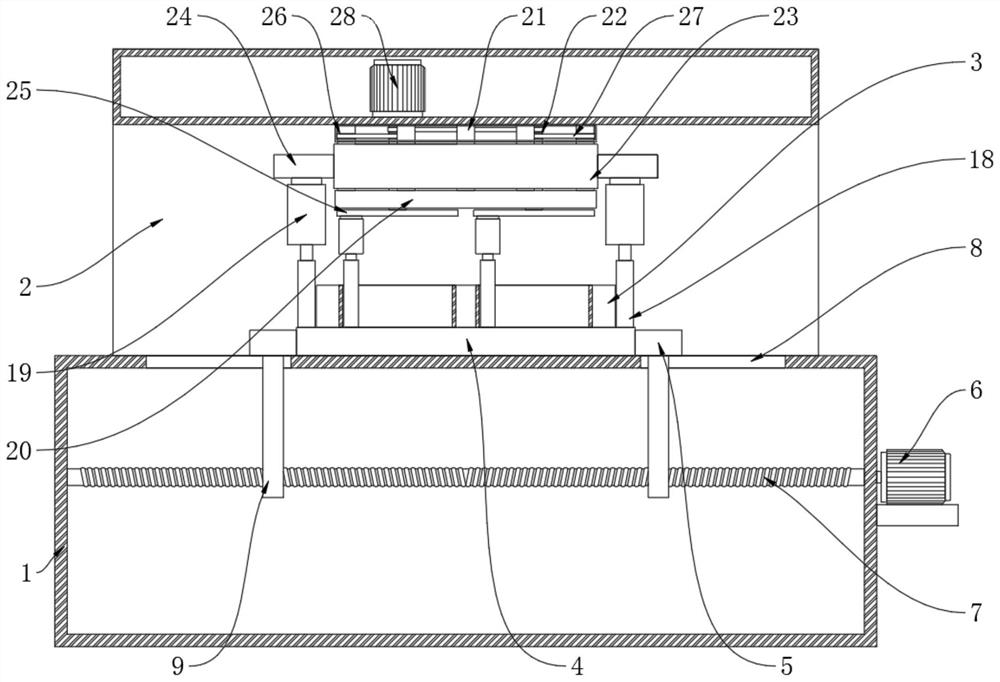

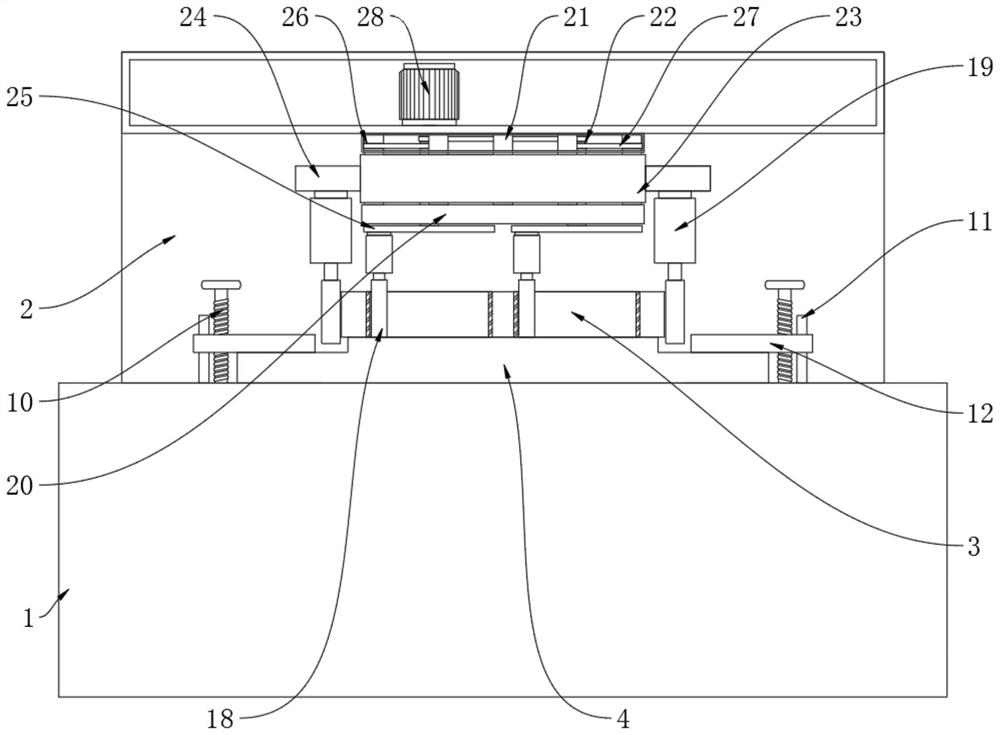

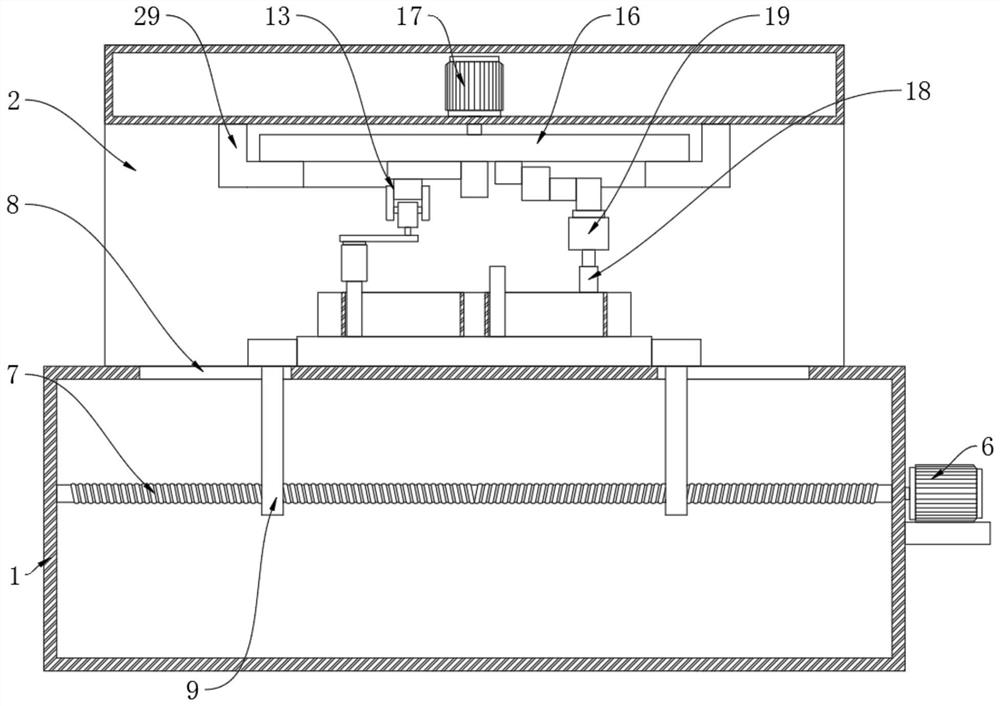

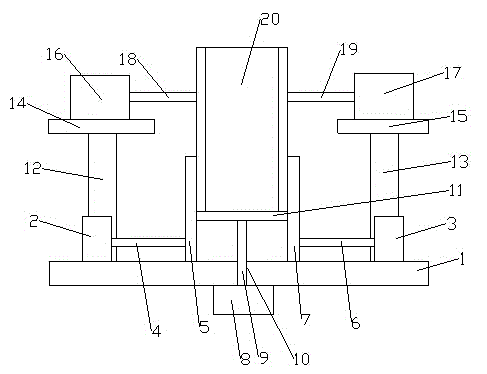

Machining process and device of gear pump

ActiveCN114310403AReduce the frequency of retentionSimplify the machining processPositioning apparatusMetal-working holdersGear pumpMachining process

The invention discloses a machining process and device of a gear pump, relates to the technical field of gear pump manufacturing, and aims to provide the machining process and device of the gear pump, which simplify the machining process and accelerate the working efficiency, and is technically characterized in that a working table is further provided with a pump core, and the bottom of the pump core is bonded with a retention piece through colloid; a positioning mechanism is arranged on the outer side of the retention piece and is used for fixing the retention piece; the pump core machining device has the technical effects that the retention piece is bonded through the colloid, the retention piece is fixed through the positioning mechanism, when the machining position of the pump core is replaced, the pump core can be directly machined without loosening the fixation of the pump core, the machining efficiency is improved, and the machining cost is reduced. The pump core retention frequency is reduced, the pump core machining process is simplified, and the pump core machining efficiency is improved; as the positioning mechanism cannot stop the cutting mechanisms at different positions from running, a plurality of cutting mechanisms can be arranged for synchronous machining.

Owner:淮安万科液压机械有限公司

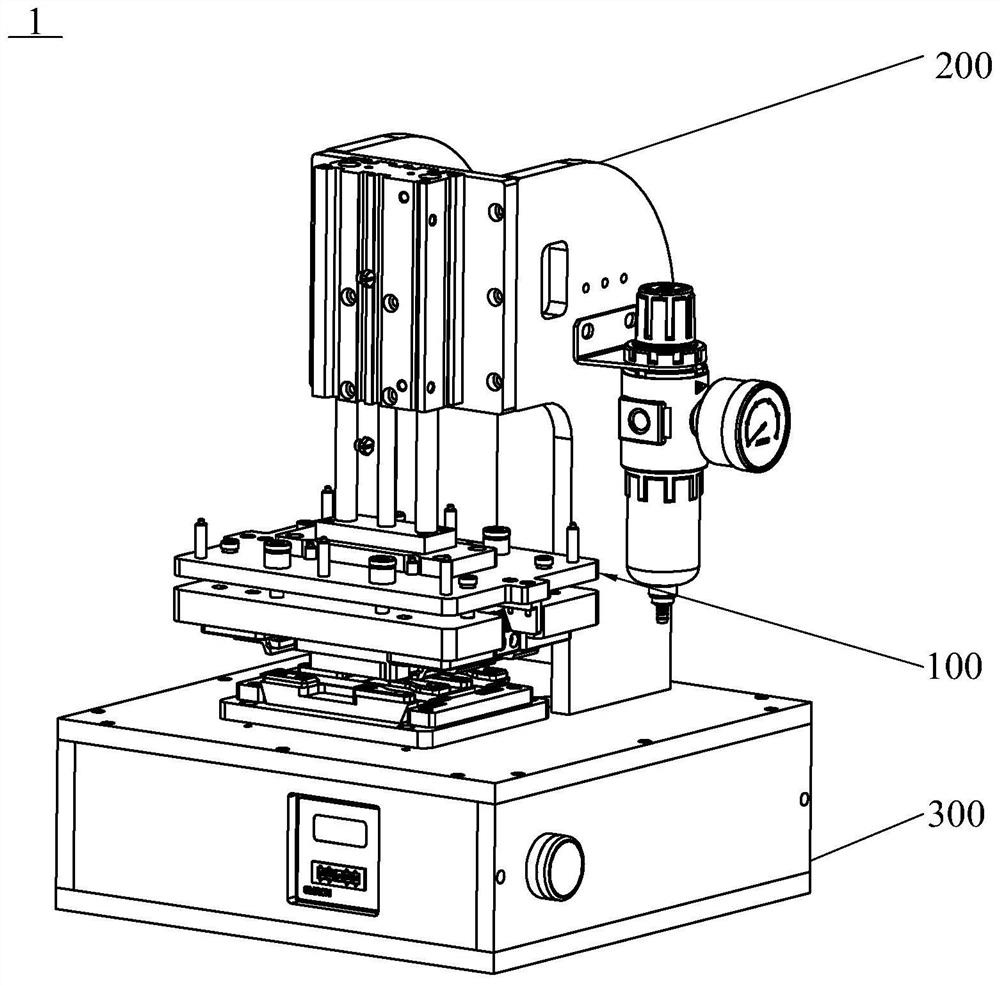

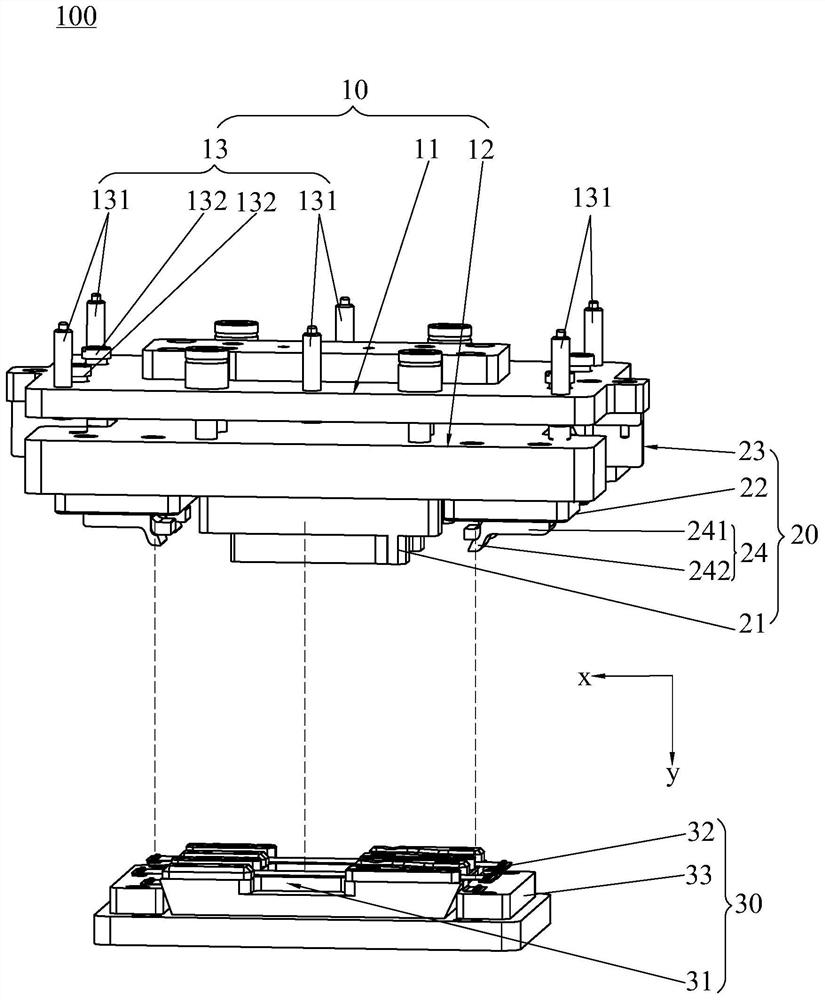

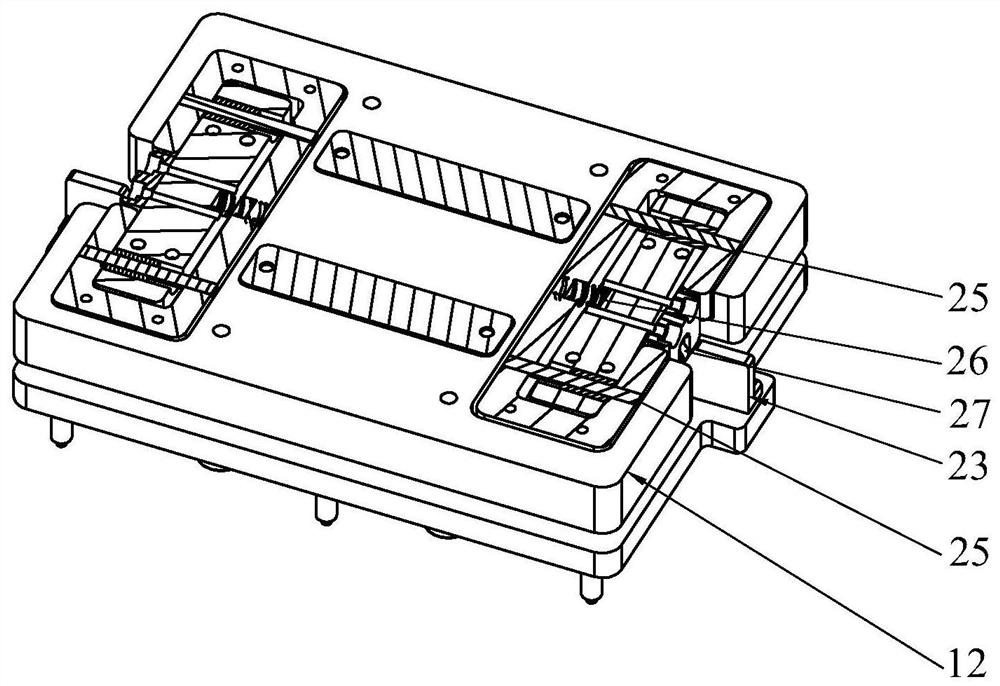

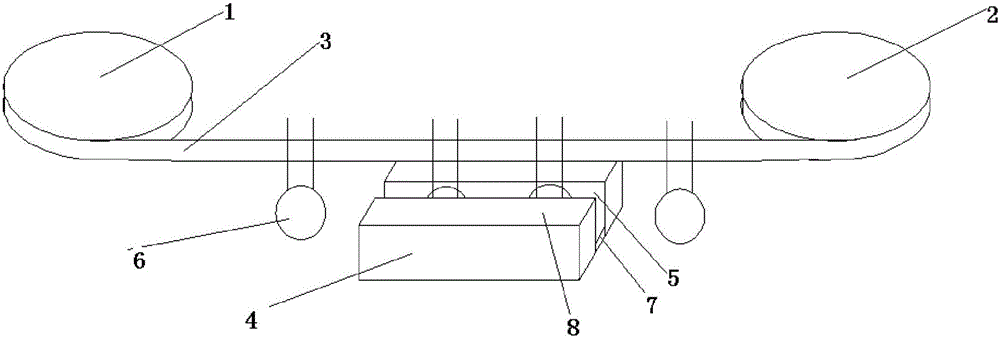

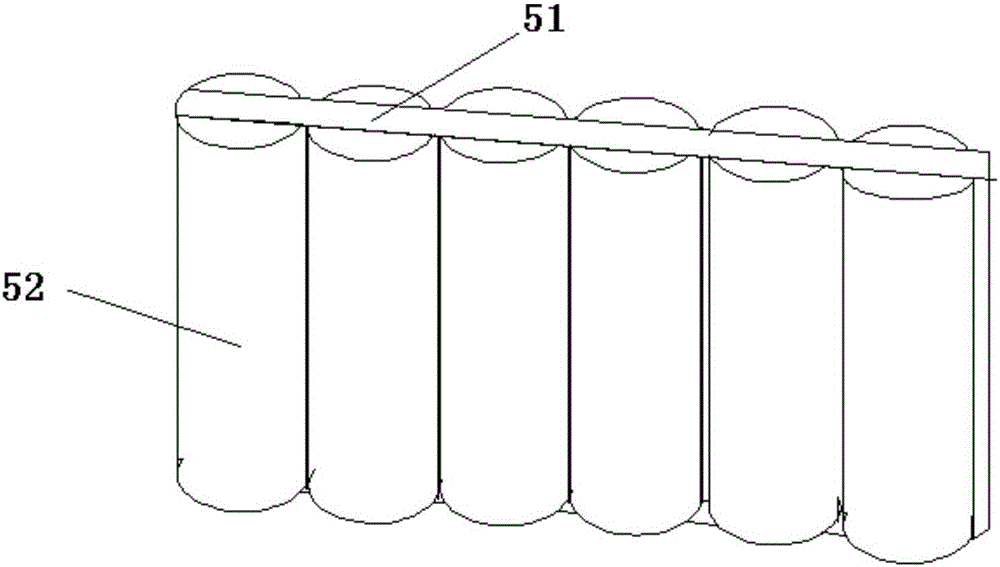

fpc bending forming device and fpc bending forming equipment

ActiveCN110978467BSimplify the machining processImprove bending efficiencyDomestic articlesMoulding deviceStructural engineering

The invention discloses an FPC bending and forming device, which includes a pressing module, a forming module, a forming part, and a bearing table. The pressing module includes a middle plate, a pressing plate and a guide assembly, and the forming module includes a pressure head, The slider and the stopper, the forming part includes the body part and the forming part, the bearing table includes the bearing part and the step part; the vertical downward linear movement of the pressure plate drives the pressure head to press and position the FPC on the bearing part and drives the forming part to press down. The right FPC is on the step part, and the stopper pushes the forming part of the molded part fixed with the slider to slide toward the wedge-shaped structure of the step part through the vertical downward linear movement of the middle plate, so that the FPC is bent to form a wedge-shaped structure. The bent shape with the same shape and structure makes the bent FPC just reach the required angle after rebounding, ensuring that it meets the installation requirements; the invention also provides a FPC bending forming equipment, which simplifies the FPC bending process and improves the bending efficiency. High efficiency, high precision, convenient operation, simple structure, greatly improving production efficiency.

Owner:DONGGUAN HUABEL ELECTRONICS TECH

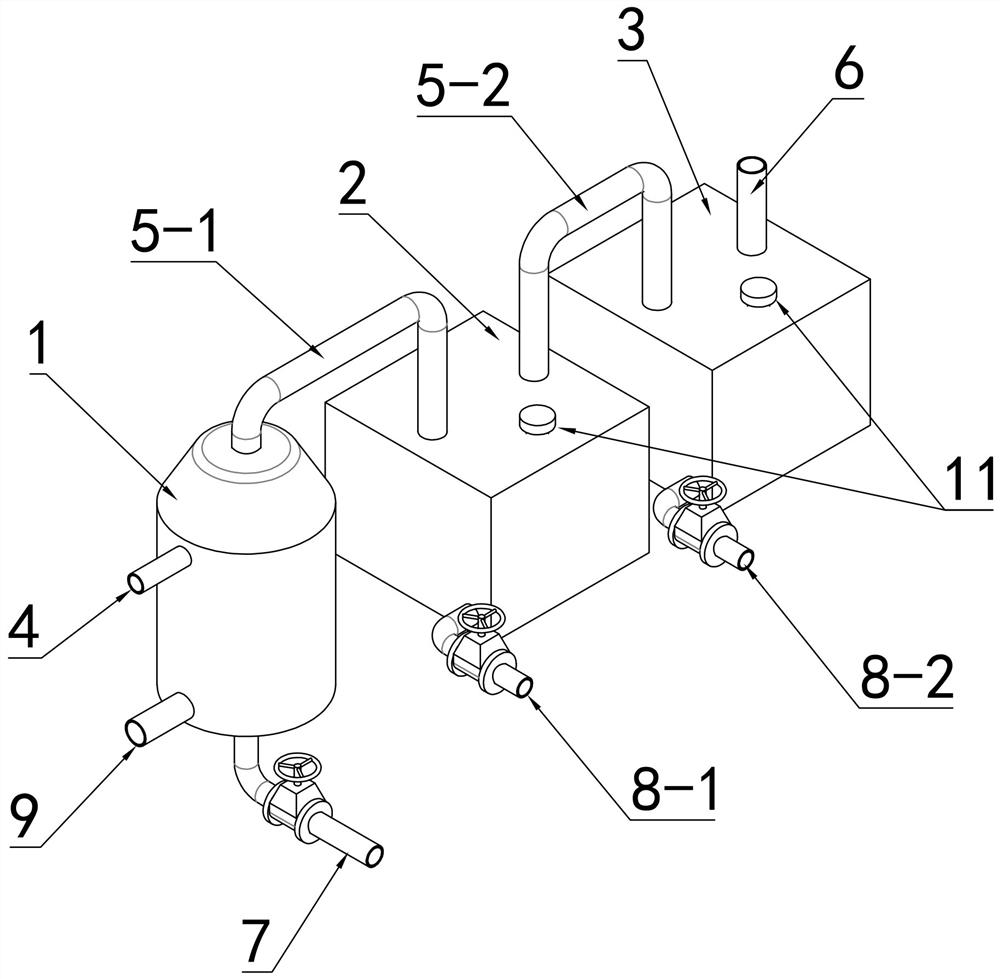

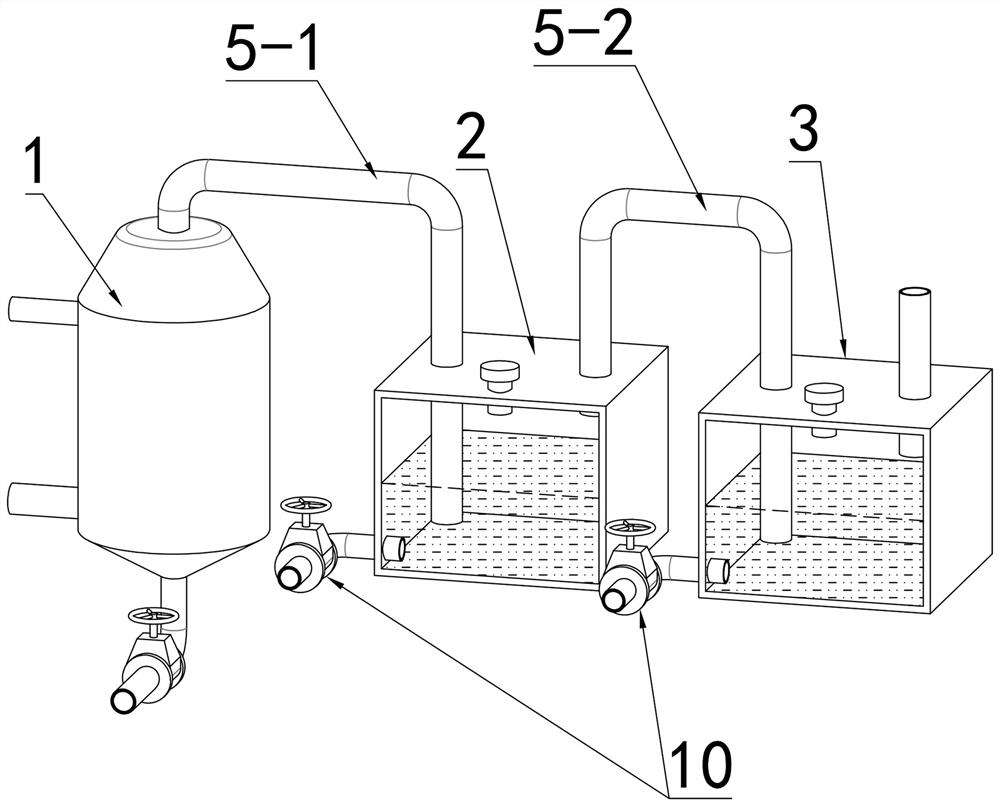

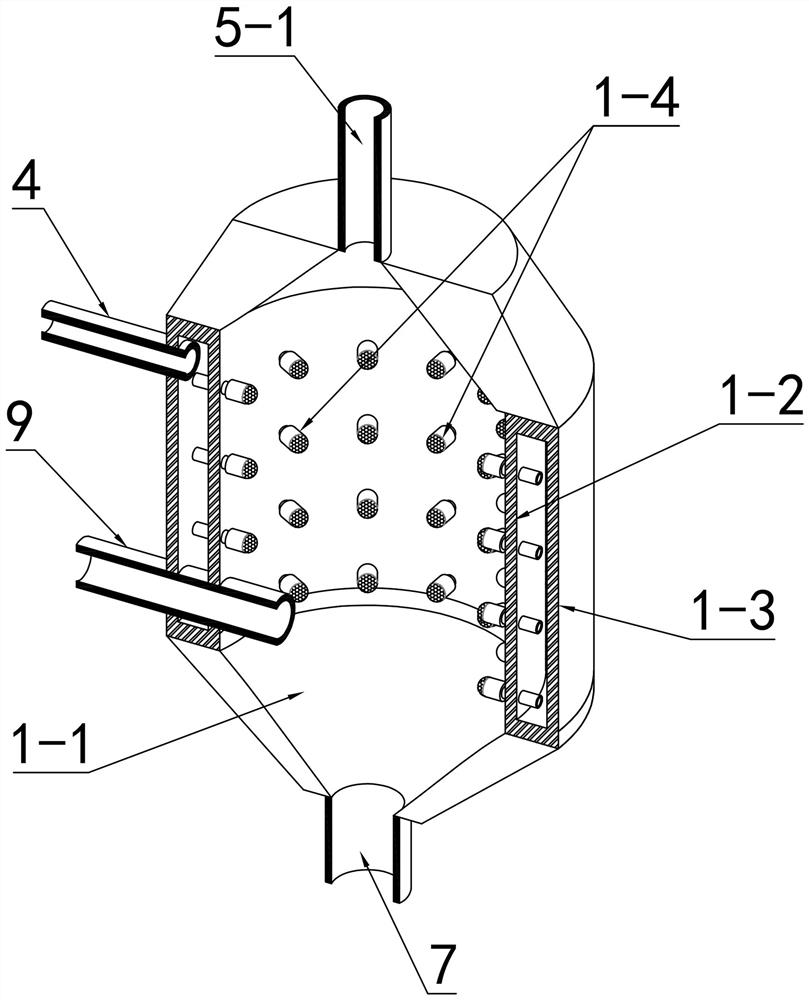

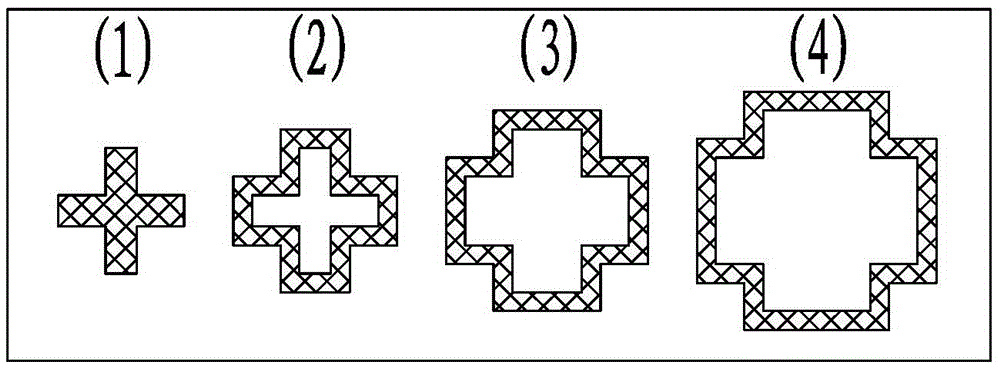

Acetylene production system with high utilization rate and production method

PendingCN114292669ASimplify the machining processSave spaceAcetylene gas generator detailsSulfuric acidNitrogen gas

According to the acetylene production system with the high utilization rate, the bottom of a reaction kettle communicates with a waste liquid pipe, the top of the reaction kettle communicates with the interior of a filter box through a first gas conveying pipe, the top of the filter box communicates with the interior of a drying box through a second gas conveying pipe, and the top of the drying box communicates with a gas outlet pipe; the acetylene production method comprises the following steps: injecting an acidic aqueous solution into a filter box, injecting concentrated sulfuric acid into a drying box, injecting a mixed solution between the cavity walls of a reaction kettle, grinding calcium carbide blocks into powder, introducing calcium carbide powder into the reaction kettle by using nitrogen, and uniformly stirring; powdery calcium carbide in the reaction kettle reacts with a mixed solution to generate acetylene-containing mixed gas, the acetylene-containing mixed gas is conveyed into the filter box through the first gas conveying pipe for reaction neutralization and then conveyed into the drying box through the second gas conveying pipe for neutralization drying, and finally the mixed gas only containing nitrogen and acetylene gas is discharged through the gas outlet pipe. And finally, separating the nitrogen from the acetylene gas to obtain pure acetylene gas.

Owner:宜昌市得心实用气体有限公司

Mask group suitable for multi-overlay multi-time sequence photoetching pattern and fabrication method of mask group

PendingCN105629659ASimplify the machining processReduce in quantityPhotomechanical apparatusOriginals for photomechanical treatmentTime sequenceGraphics

The invention provides a mask group suitable for multi-overlay multi-time sequence photoetching pattern and a fabrication method of the mask group. The mask comprises a plurality of masks, the number of the masks is (m+1), m is overlay frequencies, a plurality of pattern regions are uniformly divided on each mask, the total area of the pattern region is equal to the surface area of the mask, the number of pattern regions is at least (m+1), a shading layer is arranged on each pattern region, transmitting patterns are formed on the shading layer, the types of the transmitting patterns are (m+1), the transmitting patterns formed on pattern region at the same position of each mask are different, (m+1) transmitting patterns at the same position of the mask is arranged to be a set of overlay group, and the overlay groups at arbitrary two corresponding positions are different. During multi-overlay process of the mask group, the sequence arrangement mode of different time sequences can be acquired without considering the processing sequence of a pattern structure, the processing flows of different time sequences are facilitated, meanwhile, the number of the masks is saved, and the cost is reduced.

Owner:BEIHANG UNIV

Rotary bidirectional self-locking mechanism

PendingCN112548992ASimple structureSimplify the machining processProgramme-controlled manipulatorPhysicsEngineering

The invention relates to the technical field of mechanical parts, in particular to a rotary bidirectional self-locking mechanism. The rotary bidirectional self-locking mechanism is characterized in that an output shaft is fixed to a locking part, a mounting hole and an assembling groove are formed in the locking part, an elastic part is mounted in the mounting hole, two ends of the elastic part are propped against the side surface of a limiting column, and the side wall of the limiting column makes contact with the end of the elastic part and the outer side face of the assembling groove; and alimiting part is located on an input shaft, assembling teeth are arranged on the inner wall of the limiting part, and the limiting part and the locking part can be installed in a matched mode to forma locking assembly. According to the rotary bidirectional self-locking mechanism, planet wheels, a differential mechanism and other components are omitted, the structure is simplified, transmission levels are reduced, and mechanism efficiency is improved; and self-locking mechanisms of different sizes can be manufactured only by changing design parameters, the self-locking mechanism is suitable for different mechanical devices, positioning is conducted through a spring, the limiting column makes contact with the side face of the inner wall of a sleeve and the arc faces of assembling groove teeth all the time, therefore a self-locking return stroke gap is eliminated, and the safety and reliability of the self-locking mechanism are greatly improved.

Owner:SHANGHAI AI CARE MEDICAL TECH CO

Low-dust capacitor encapsulation machine

ActiveCN105895391ANo Cleaner RequiredSimplify the machining processFixed capacitor dielectricEncapsulating capacitors apparatusCapacitanceEngineering

The invention discloses a low-dust capacitor encapsulation machine, which comprises a left runner, a right runner, a belt and a powder box, wherein the belt is arranged on the left runner and the right runner; the powder box is arranged under the belt; the powder box is a square container with an opening in the upper part; two baffle plates for dividing the powder box into a front part and a rear part are arranged in the middle of the powder box; a box cover is arranged at the opening of the powder box; the box cover is divided into a front cover and a rear cover by the two baffle plates; a channel is formed between the two baffle plates; a capacitor can pass through the channel; openings in two ends of the channel are arranged in the left side surface and the right side surface of the powder box; each baffle plate comprises a border and a plurality of closely arranged rotary columns; two ends of a shaft of each rotary column are arranged in the upper side and the lower side of the border respectively; and powder can be adsorbed on the surfaces of the rotary columns. According to the low-dust capacitor encapsulation machine, the belt is not easily polluted; the procedure is simple; the powder is encapsulated evenly; and dust is not easily sprayed.

Owner:KUNSHAN MICRO CAPACITORS ELECTRONICS

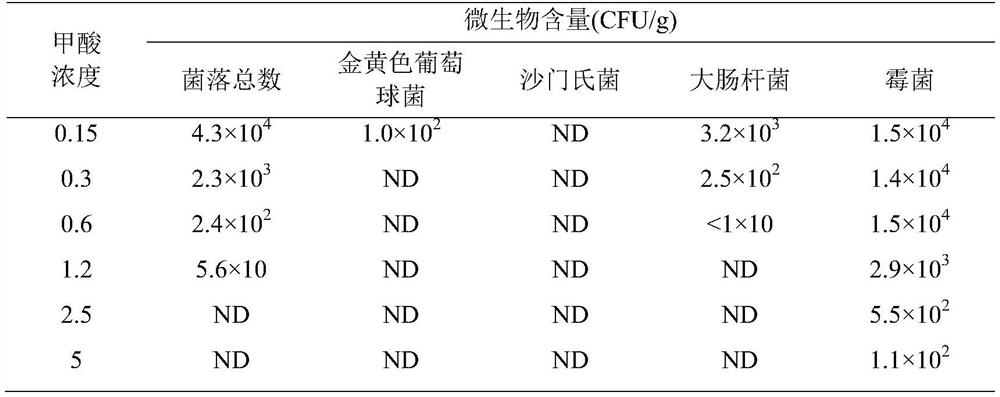

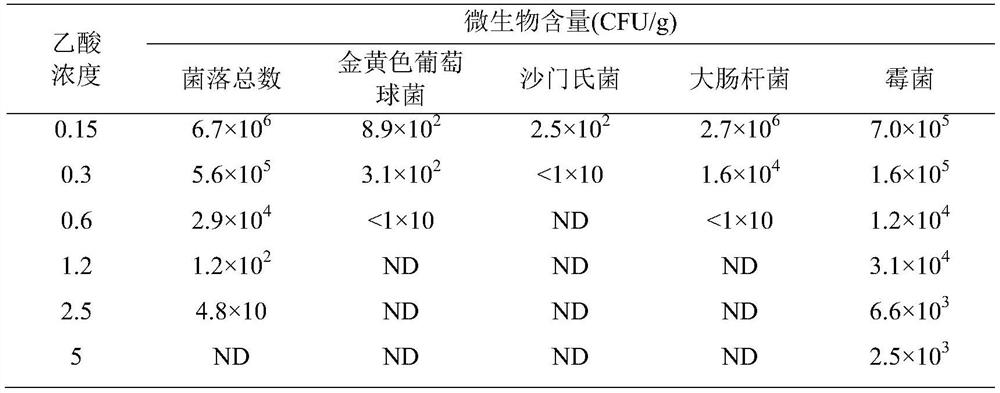

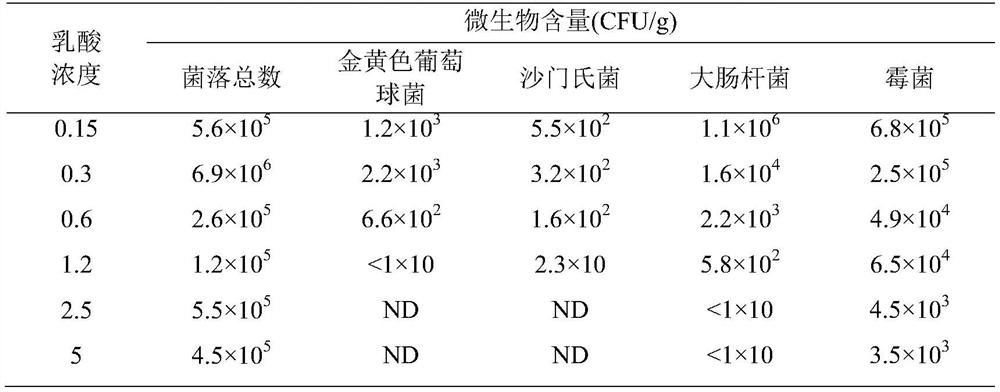

Kitchen waste preservative and preservation method

PendingCN113787079AImprove freshnessSimplify the machining processBiocideSolid waste disposalAcidulantFormic acid

The invention discloses a kitchen waste preservative and a preservation method. The preservative for the kitchen waste at least contains one of the following acidifiers: formic acid, acetic acid, lactic acid, citric acid, malic acid and tartaric acid. The preservative for the kitchen waste comprises, by mass percent, 0-5% of formic acid, 0-5% of acetic acid, 0-5% of lactic acid, 0-5% of citric acid, 0-5% of malic acid and 0-5% of tartaric acid. The preservative creates conditions for resource utilization of the kitchen waste, also makes contributions to environmental protection and conservation-minded society, and has good economic and social value.

Owner:SHENZHEN UNIV

Manufacturing process of thrust washer

InactiveCN102777463ASimplify the machining processHigh technical standardsFastening meansSteel platesManufacturing quality

The invention relates to a manufacturing process of a thrust washer, which comprises the steps of: stamping of a stainless steel plate with the thickness of 0.5mm into a thrust washer shape on a cold pressing mold of a stamping machine, finishing of an undulated edge and a semicircular stopper of a shaft sleeve, drilling and cutting of a rotating shaft hole, removal of sharp corners and burrs formed in processing, removal of oil and rust on the surface, and electropolishing of the surface. By adopting the manufacturing process of the thrust washer, the manufacturing quality and product requirements of components can be ensured.

Owner:YANTAI GOLD KING TECH & TRADING

Clutch machine cover extending arm support drilling device

InactiveCN106270630ASimplify the machining processImprove processing efficiencyAutomatic workpiece supply/removalLarge fixed membersClutchEngineering

The invention belongs to the technical field of machining and particularly relates to a clutch machine cover extending arm support drilling device. A support is provided with a first movable air cylinder and a second movable air cylinder. A first movable rod is connected to the first movable air cylinder. A first limiting plate is connected to the first movable rod. A second movable rod is connected to the second movable air cylinder. A second limiting plate is connected to the second movable rod. A machined support is arranged between the first limiting plate and the second limiting plate. A support plate is arranged under the machined support. A lifting rod is connected to the lower bottom face of the support plate. The support is provided with a round hole. The lifting rod penetrates through the round hole and is connected with a lifting air cylinder. The support is further provided with a first support column and a second support column. The first support column is provided with a first support plate provided with a first motor. The second support column is provided with a second support plate provided with a second motor.

Owner:TIANJIN DINGCHENG ALUMINUM DIE CASTING

Internally embedded component packaging method and the internally embedded component packaging structure

ActiveCN106206496AReduce the process of storage tank and drillingSimplify the machining processPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringMetal

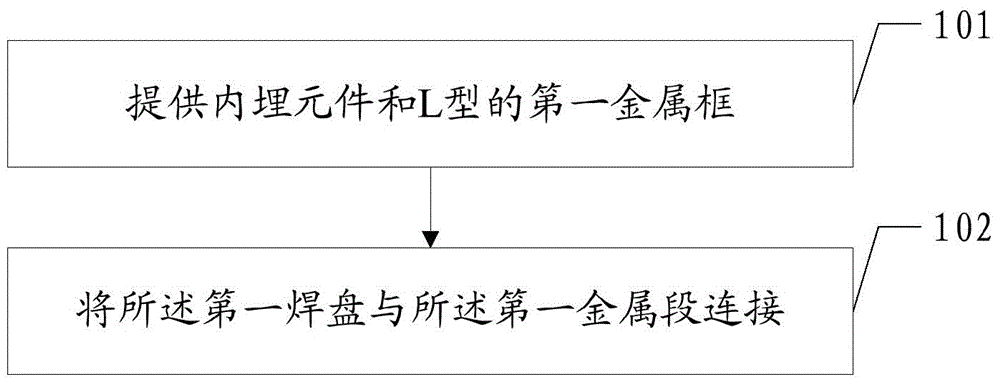

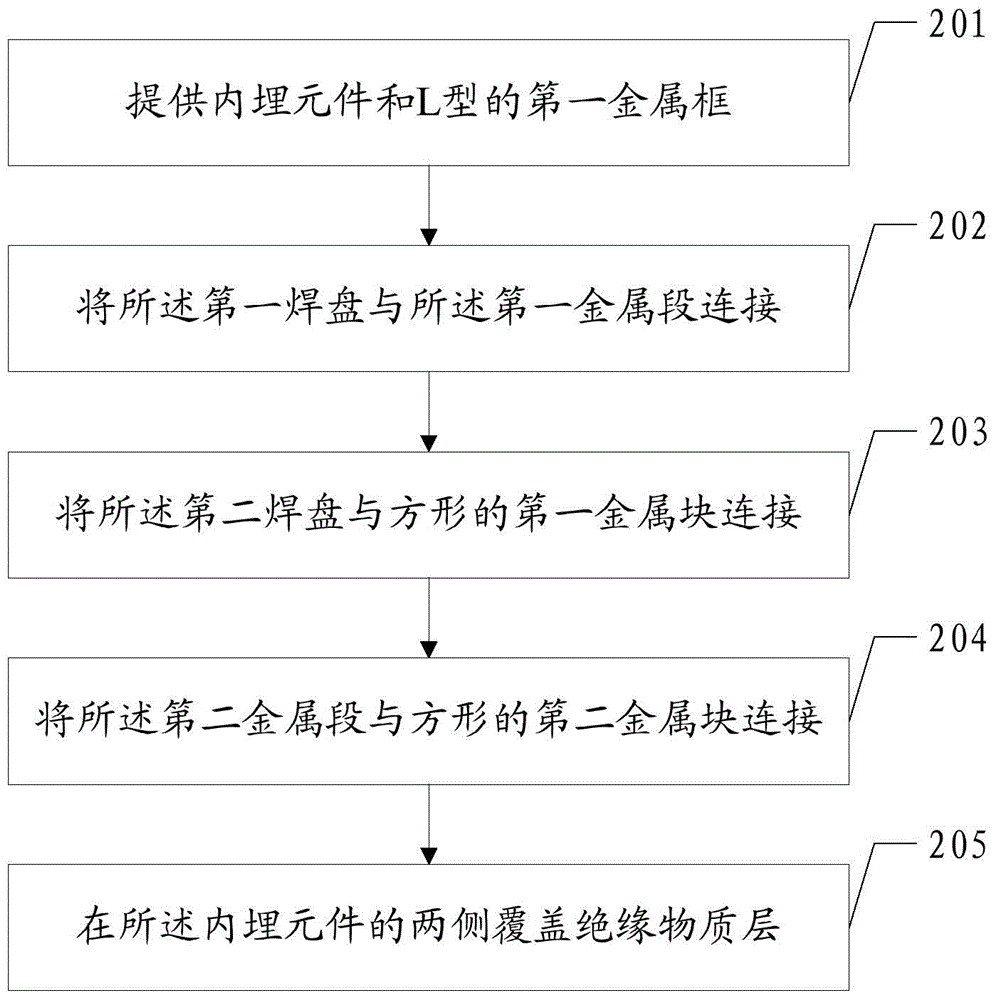

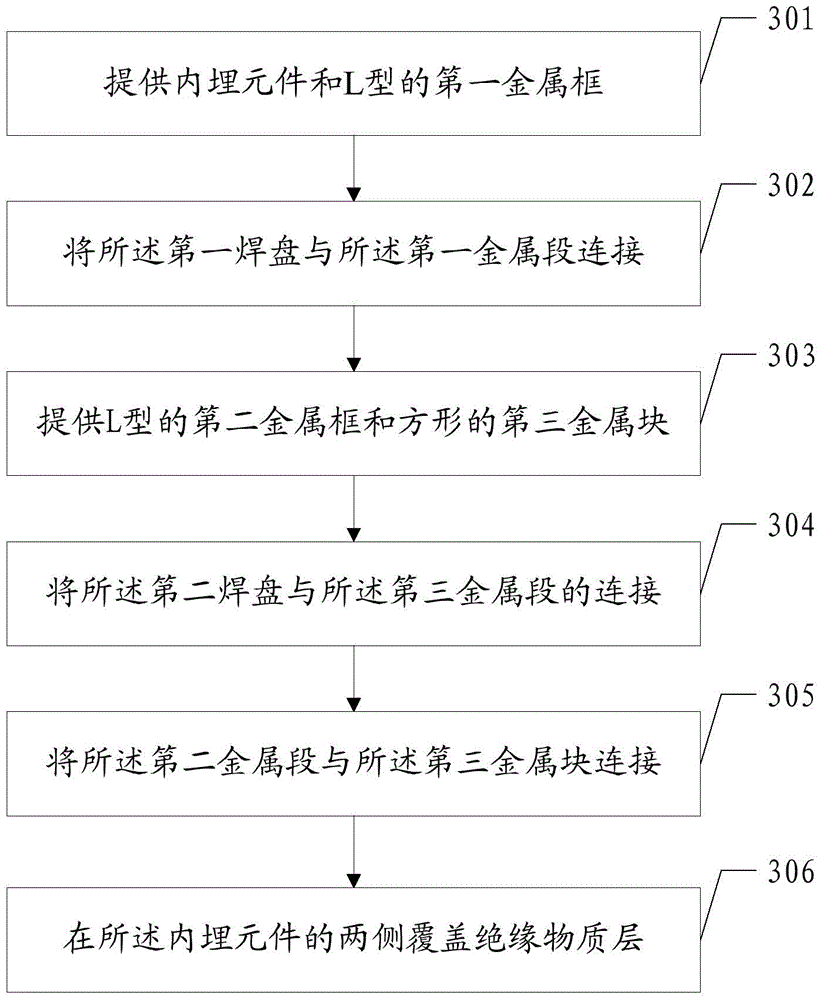

According to one embodiment of the invention, an internally embedded component packaging method is provided to simplify the processing procedures and increase production efficiency. The method comprises the following steps: providing an internally embedded component and an L-shaped first metal frame. The internally embedded component comprises a first welding plate and a second welding plate that are disposed symmetrically; the first L-shaped metal frame comprises a first metal section and a second metal section, both being perpendicular to each other. The length of the first metal section is greater than that of the internally embedded component and the length of the second metal section is equal to the thickness of the internally embedded component. The first welding plate is connected with the first metal section so that the projection zones of the internally embedded component and the second metal section in the horizontal direction are overlapped. According to the embodiment of the invention, an internally embedded component packaging structure is also provided to simplify the processing procedures and increase production efficiency.

Owner:SHENNAN CIRCUITS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com