Patents

Literature

37results about How to "Clear wood grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

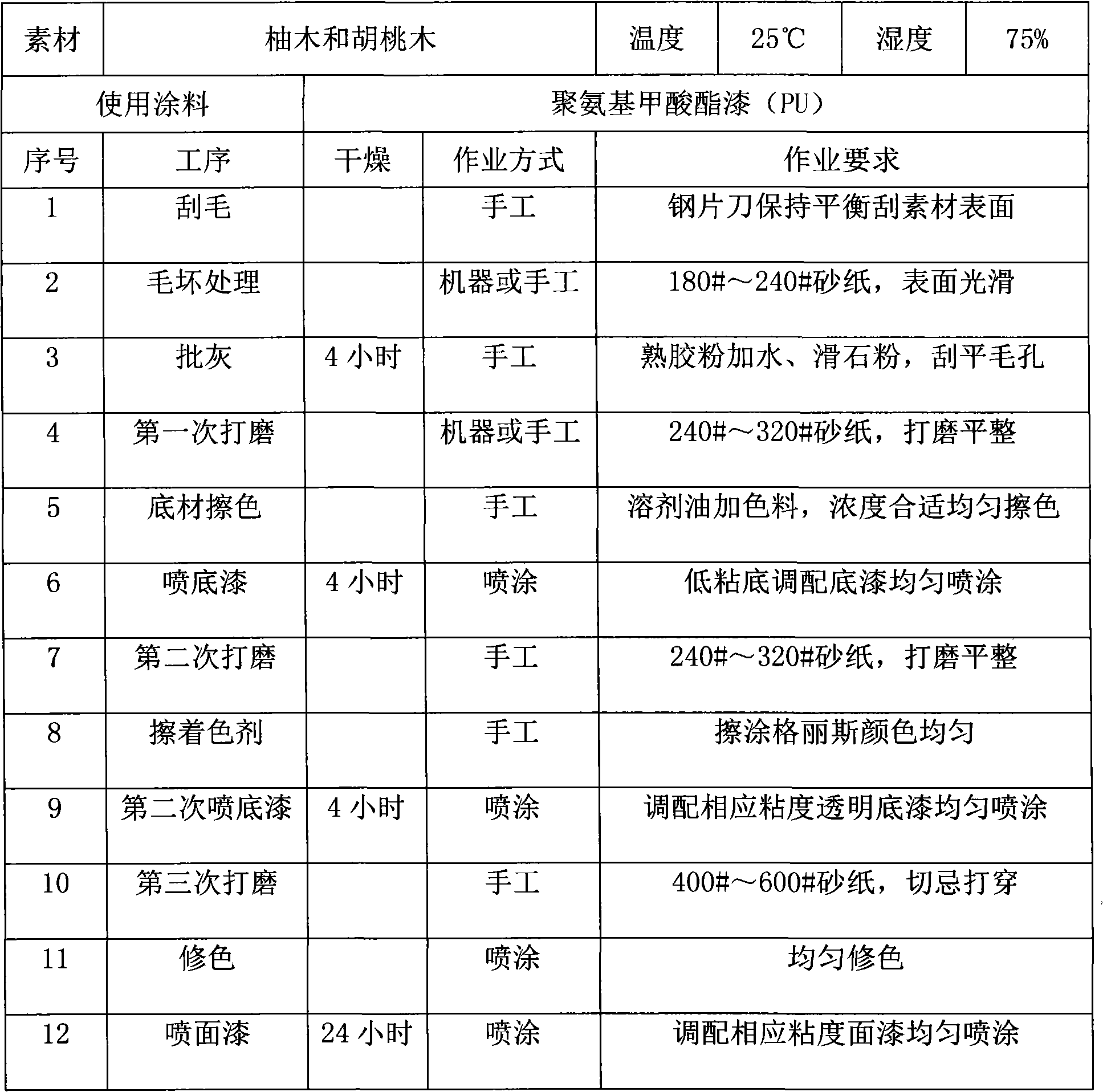

Paint coating process for wooden furniture

InactiveCN101670335AShorten the timeConsistent colorPretreated surfacesCoatingsRoughcastMaterials science

The invention relates to the field of paint coating processes, in particular to a paint coating process for wooden furniture. The paint coating process for the wooden furniture comprises the followingworking procedures: (1) scraping, (2) blank treatment, (3) plastering, (4) primary polishing, (5) base material coloring, (6) base paint spraying, (7) secondary polishing, (8) colorant coating, (9) secondary base paint spraying, (10) third polishing, (11) tinting, and (12) finish paint spraying. The paint coating process for the wooden furniture provided by the invention overcomes the defects that the blank treating and polishing time is long and the plane is not easy to be smoothened, improves the color definition of the furniture, and improves the visual effect and appreciation of the furniture.

Owner:莫有根

Ultraviolet light solidified wear resistant lacquer in use for coating layer on surface of dense board plastes

InactiveCN1696225AImprove performanceSoft matte finishPolyurea/polyurethane coatingsMethacrylateHigh density

An ultraviolet solidified antiwear paint for the surface of high-density board with hot-pressed surficial paper layer contains proportionally acrylate (or methylacrylate) modified amino resin, polyurethane acrylate or polyurethane methylacrylate, epoxy acrylate or epoxy methyl acrylate, acrylate or methylacrylate, optical trigger, antiwear inorganic powder and dulling powder.

Owner:湖南亚大新材料科技股份有限公司

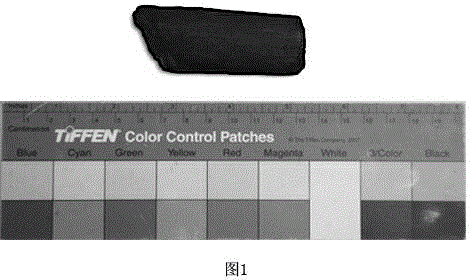

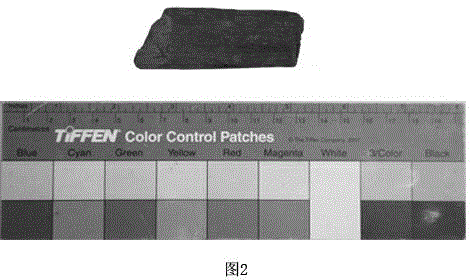

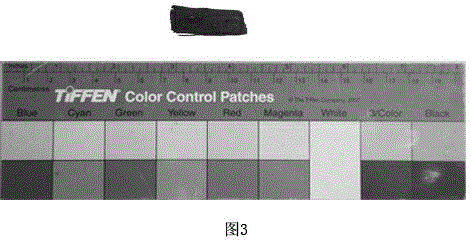

Supercritical dewatering and drying method for small water-saturated bamboo and wood articles

InactiveCN103331793ATo achieve the purpose of dehydrationClear wood grainWood treatment detailsWood impregnation detailsSupercritical dryingPulp and paper industry

The invention relates to a supercritical dewatering and drying method for small water-saturated bamboo and wood articles, belonging to the technical field of dewatering protection for cultural relics. The small water-saturated bamboo and wood articles of which the length, the width and the height are respectively at most 20cm are respectively soaked for certain time in three kinds of ethanol with different concentrations, then the supercritical drying method is adopted, and therefore the water of the water-saturated bamboo and wood articles is gradually replaced to achieve the purpose of dewatering. Compared with the prior art, the supercritical dewatering and drying method has the advantages that the purpose of dewatering of the water-saturated bamboo and wood articles can be achieved without filling chemical materials; the dewatered bamboo and wood articles have clear wood grains, and the color tends to be normal; the dewatered bamboo and wood articles have good stability under the condition of temperature and humidity fluctuation, and each shrinking percentage is within 5 percent; the complete shape of the cultural relics can be completely ensured, and the method conforms to the basic principle, namely the minimal intervention to protection of the cultural relics; the method has high research and extension values and significance.

Owner:荆州文物保护中心

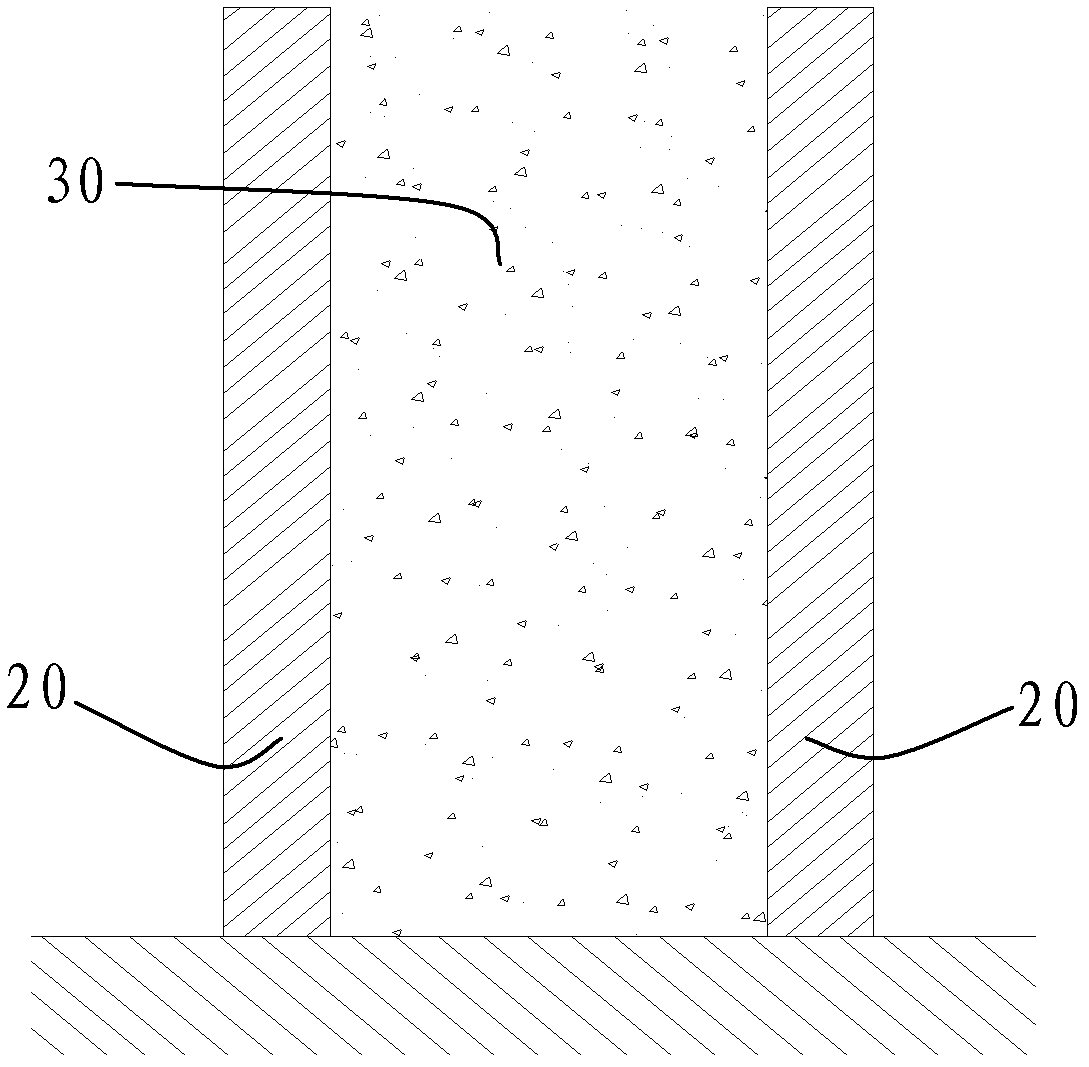

Construction method of fair-faced concrete wall with wood grain finish

InactiveCN102561678AClear wood grainConcave and convexForms/shuttering/falseworksBuilding material handlingHigh densityMaterials science

The invention discloses a construction method of a fair-faced concrete wall with wood grain finish, wherein the construction method comprises the steps of extracting wood grain effect from raw wood, using the extracted wood grain effect to carve a steel die with the wood grain effect; using the steel die with the wood grain effect to press a high-density plate with the wood grain effect; and using the high-density plate with the wood grain effect as a template to pour the fire-faced concrete wall. The fair-faced concrete wall poured by the invention has clear wood grains, concave-convex feeling and uniform color, and cannot do any repairing or toning; the template can be used repeatedly and the same effect can be still achieved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

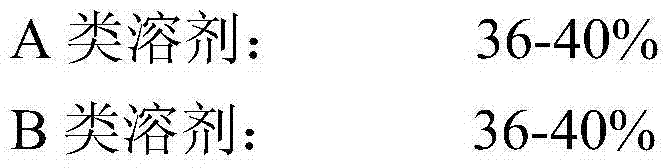

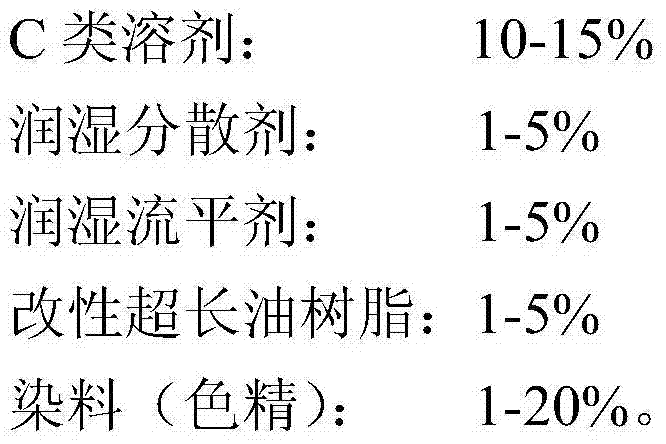

Oily brush-off agent as well as preparation method and application thereof

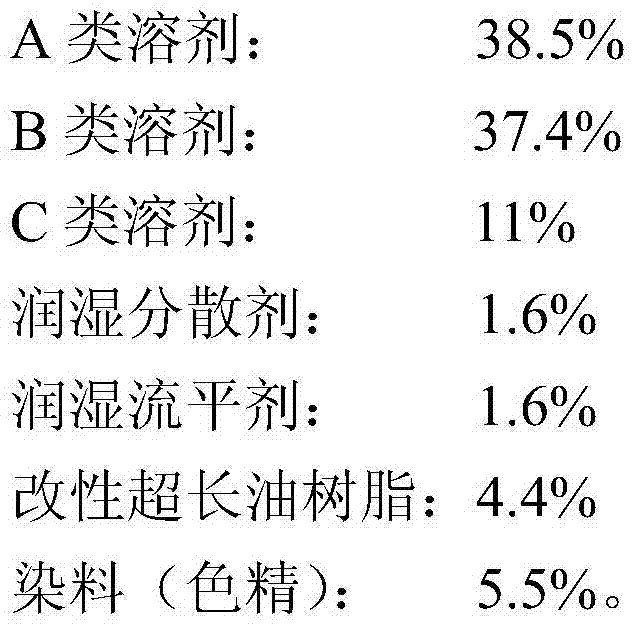

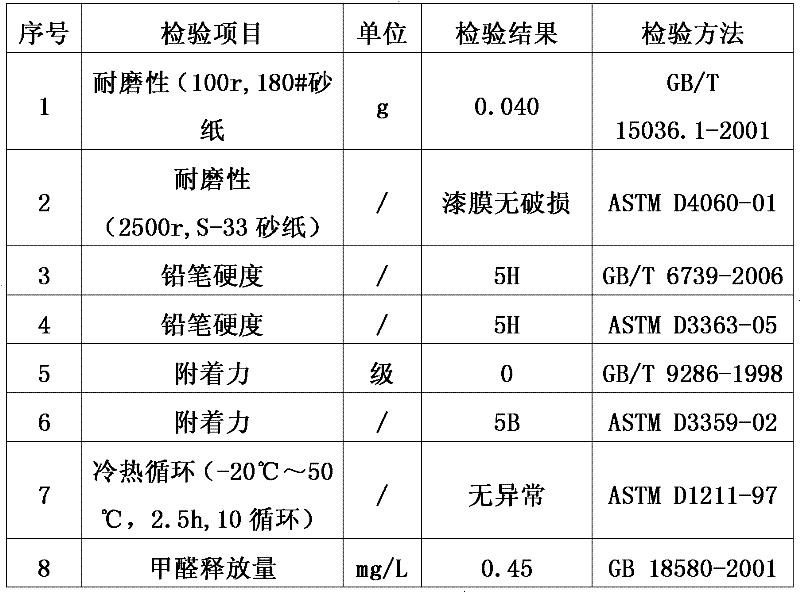

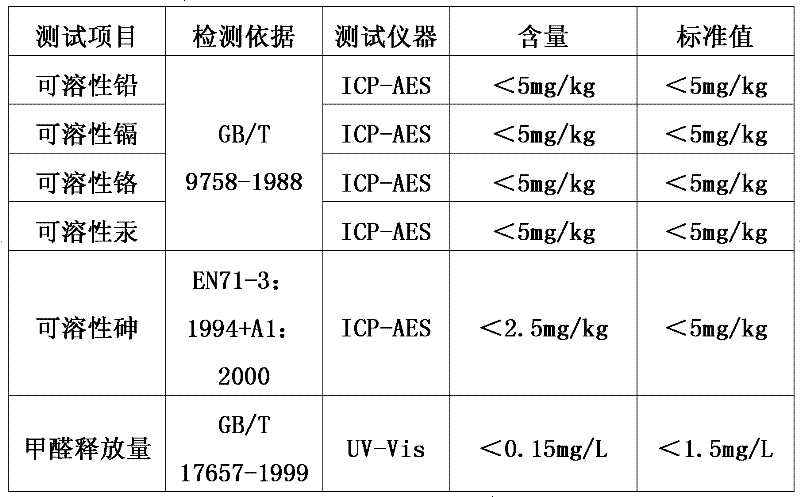

The invention discloses an oily brush-off agent as well as a preparation method and application thereof. The oily brush-off agent is prepared from 36-40% of type-A solvent, 36-40% of type-B solvent, 10-15% of type-C solvent, 1-5% of wetting dispersant, 1-5% of wetting levelling agent, 1-5% of modified overlength oily resin and 1-20% of colour concentrate, wherein the type-A solvent preferably is a mixture of propylene glycol, butyl cellosolve and S-100#, the type-B solvent preferably is a mixture of methyl isobutyl ketone and butyl ester, and the type-C solvent preferably is ethyl ester. The oily brush-off agent disclosed by the invention can be used for decoration for carpentry homes, and can be constructed by the processes of spray-coating, brush-coating, rolling-coating, wiping-coating and the like. The oily brush-off agent disclosed by the invention can be directly constructed on a transparent primer paint instead of being added in a transparent finish paint, and simple to construct, and the furniture made from the oily brush-off agent are abundant and bright in colour, clear in wood grain, high in stereoscopic impression, labour-saving and material-saving, and capable of saving resources and achieving a decoration effect.

Owner:NIPPON PAINT GUANGZHOU

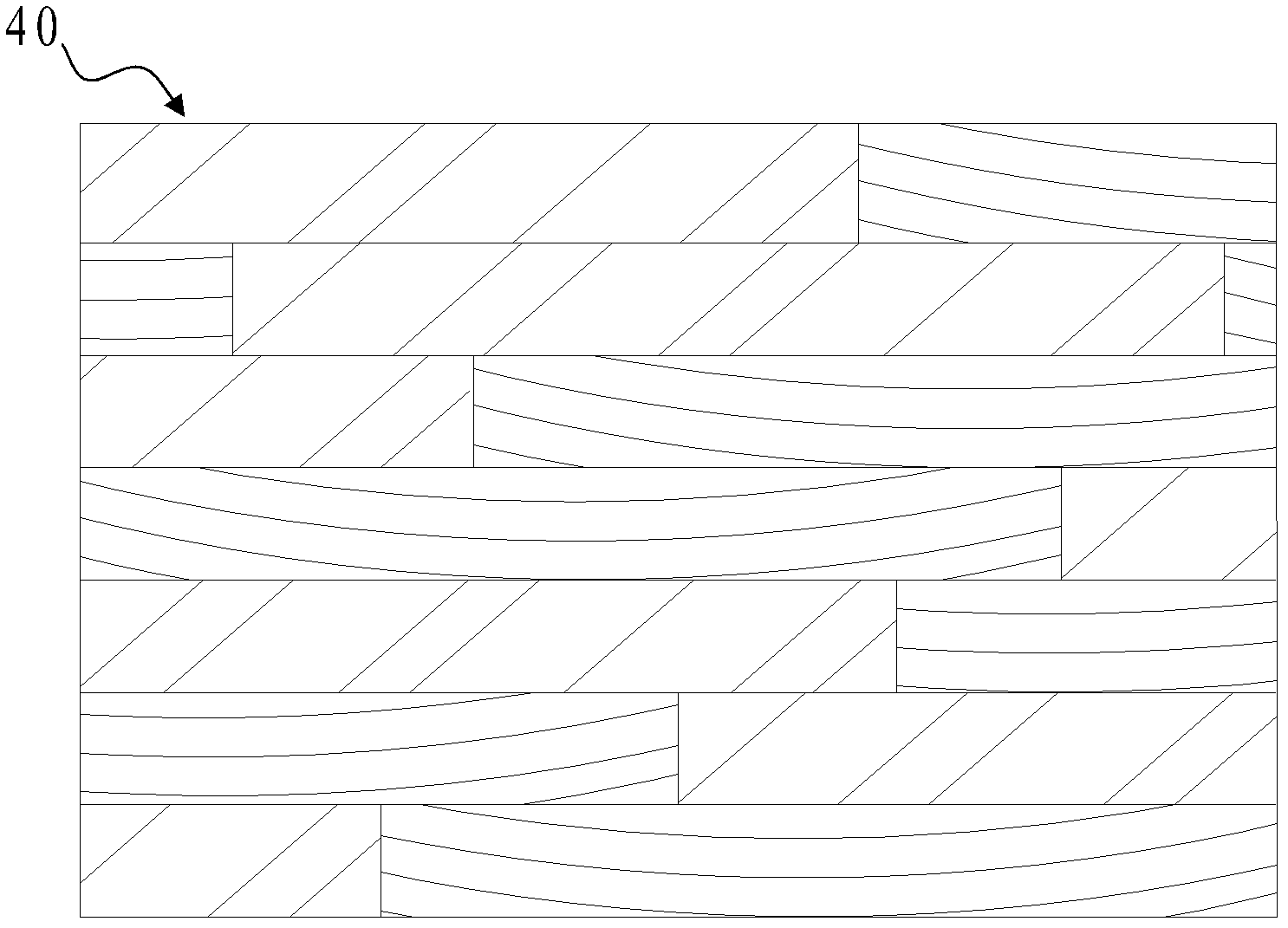

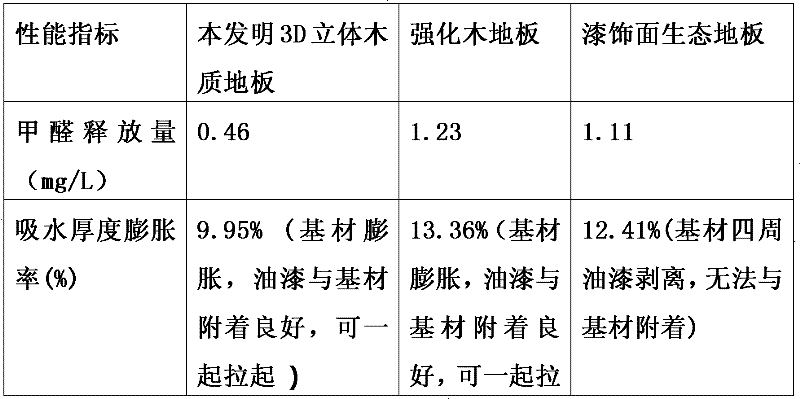

Method for producing high-emulation three-dimensional (3D) wood floor and high-emulation 3D wood floor

ActiveCN101885200BThree-dimensionalUnique wood grain printing effectWood treatment detailsWood dampingMethods of productionVisual perception

The invention discloses a method for producing a 3D wood floor and the 3D wood floor. The method comprises the following steps of: processing the surface of a base material to form a convex-concave three-dimensional surface; transferring wood grain on a rubber covered roller by using a steel roller with the wood grain, printing the wood grain on a substrate for 2 to 3 times by using the rubber covered roller, and coating finish on the substrate surface for 1 to 2 times; and printing the wood grain on the substrate for 2 to 3 times; and finally, coating finish on the substrate surface for 2 to 5 times. The wood floor produced by the method has high-emulation 3D wood grain layering and visual effects; the wood grain is clear and very vivid; and the produced floor voids repeated wood grain and has a good foot feel and the smooth and soft surface.

Owner:ZHEJIANG SHIYOU TIMBER

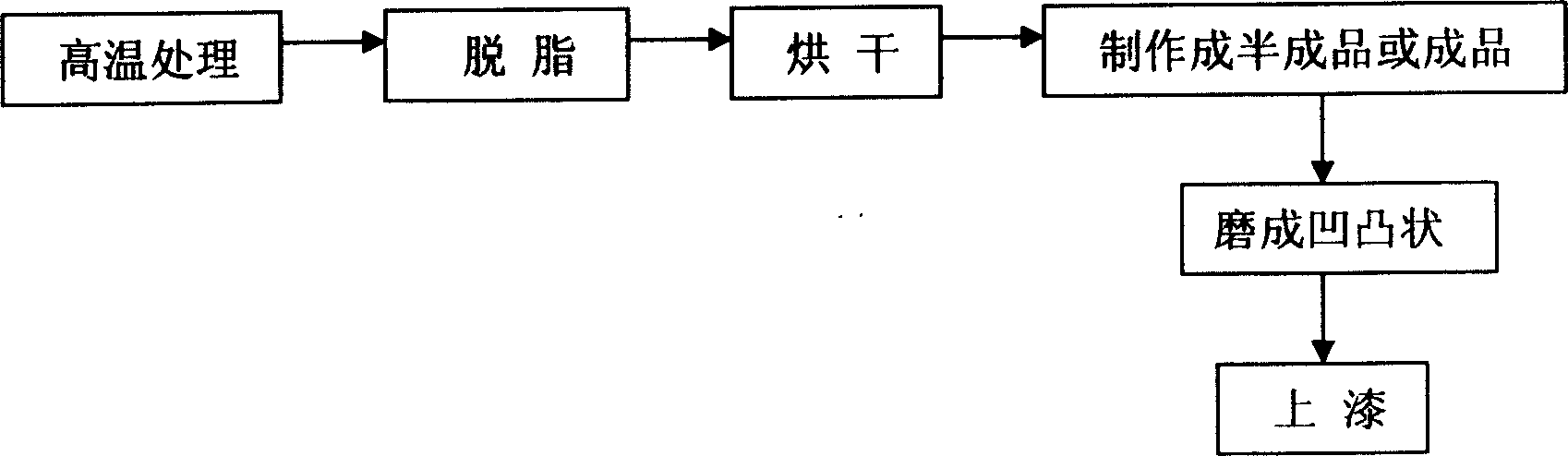

Wood semi-product or finished product working process

InactiveCN1709665AClear wood grainStrong sense of three-dimensional concave and convexWood working apparatusPulp and paper industryMetal

Owner:徐群华

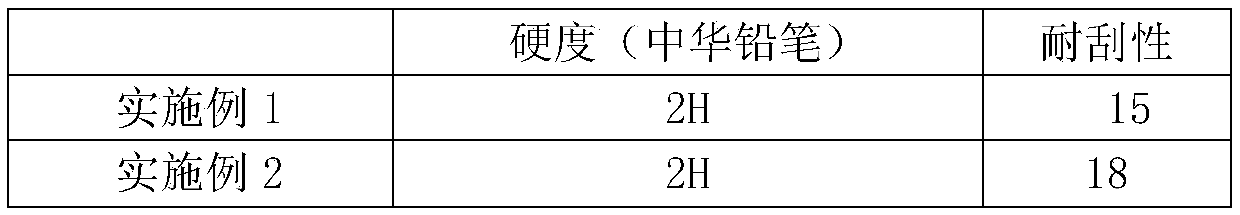

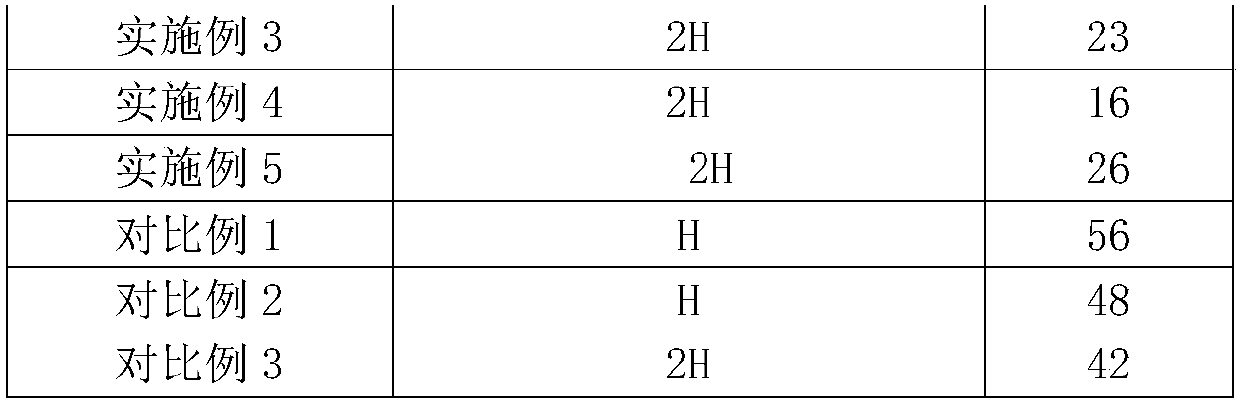

Water-based high-clarity high-scratch-resistance five-splitting main finish paint as well as preparation method thereof and double-component clear surface paint

ActiveCN109575776AHigh hardnessImprove permeabilityAntifouling/underwater paintsPaints with biocidesNano siliconWater based

The invention belongs to the field of special paint, and discloses water-based high-clarity high-scratch-resistance five-splitting main finish paint. The water-based high-clarity high-scratch-resistance five-splitting main finish paint comprises the following components in parts by weight: 70 to 80 parts of hydroxyl acrylic emulsion, 5 to 10 parts of nano silicon sol, 4 to 8 parts of glass powder / aluminum oxide and an appropriate amount of pH regulator, thickening agent and water for adjusting the system to the appropriate viscosity and pH value; and the hydroxyl value of the hydroxyl acrylicemulsion is 3. The water-based high-clarity high-scratch-resistance five-splitting main finish paint has the advantages of rapidness in curing, good water resistance and scratch resistance.

Owner:YINGDE YAJIA PAINT

Semitransparent electrine raw umber smell cleaning type polyurethane woodenware paint and preparation method thereof

InactiveCN104726002AHigh hardnessSmall steric hindrancePolyurea/polyurethane coatingsPigment pastesSolventKetone

The invention relates to a semitransparent electrine raw umber smell cleaning type polyurethane woodenware paint and a preparation method thereof. The paint comprises a component A and a component B according to a weight ratio of 1:0.5; the component A is composed of smell cleaning type alkyd resin, extinction powder, a dispersant, an electrine color paste, a leveling agent, an antifoaming agent, an anti-settling agent and a solvent; and the component B is a non-benzene curing agent based on TDI and HDI trimer or adduct. The semitransparent electrine raw umber smell cleaning type polyurethane woodenware paint prepared in the invention does not contain aromatic hydrocarbons, aldehyde, ketone or heavy metals, and can reach a smell cleaning effect 48h after a film is formed by coating the paint; the paint has the advantages of no settlement, good levelability, good handle, high scratch resistance and no ghosting in the storage process; and the paint can be coated on woodenware to realize clear and intensive wood grains and make furniture elegant, noble, natural and comfortable, adapts to modern aesthetics, is popular in the market and is loved by users. The paint can be widely used to realize surface decoration protection of woodenwares, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Open grain displaying paint process for wooden door

InactiveCN102049379ATake advantage ofRetain natural texturePretreated surfacesCoatingsRoughcastMaterials science

The invention discloses an open grain displaying paint process for a wooden door. The process comprises the steps of treating a blank, brushing a base paint and brushing a finishing paint. In the blank treatment, according to natural grain polishing on the surface of the wooden door, fine polishing is adopted at the position of clear grains, and repeated polishing is adopted at the position of unclear grains, so that the natural wood grains can be clearly displayed, the decorative panel with dissatisfactory grains can be fully utilized, and material and manpower are saved; and the manufactured wooden door keeps woody natural grains of the decorative panel, and the grains are clear.

Owner:吴江市固友木门厂

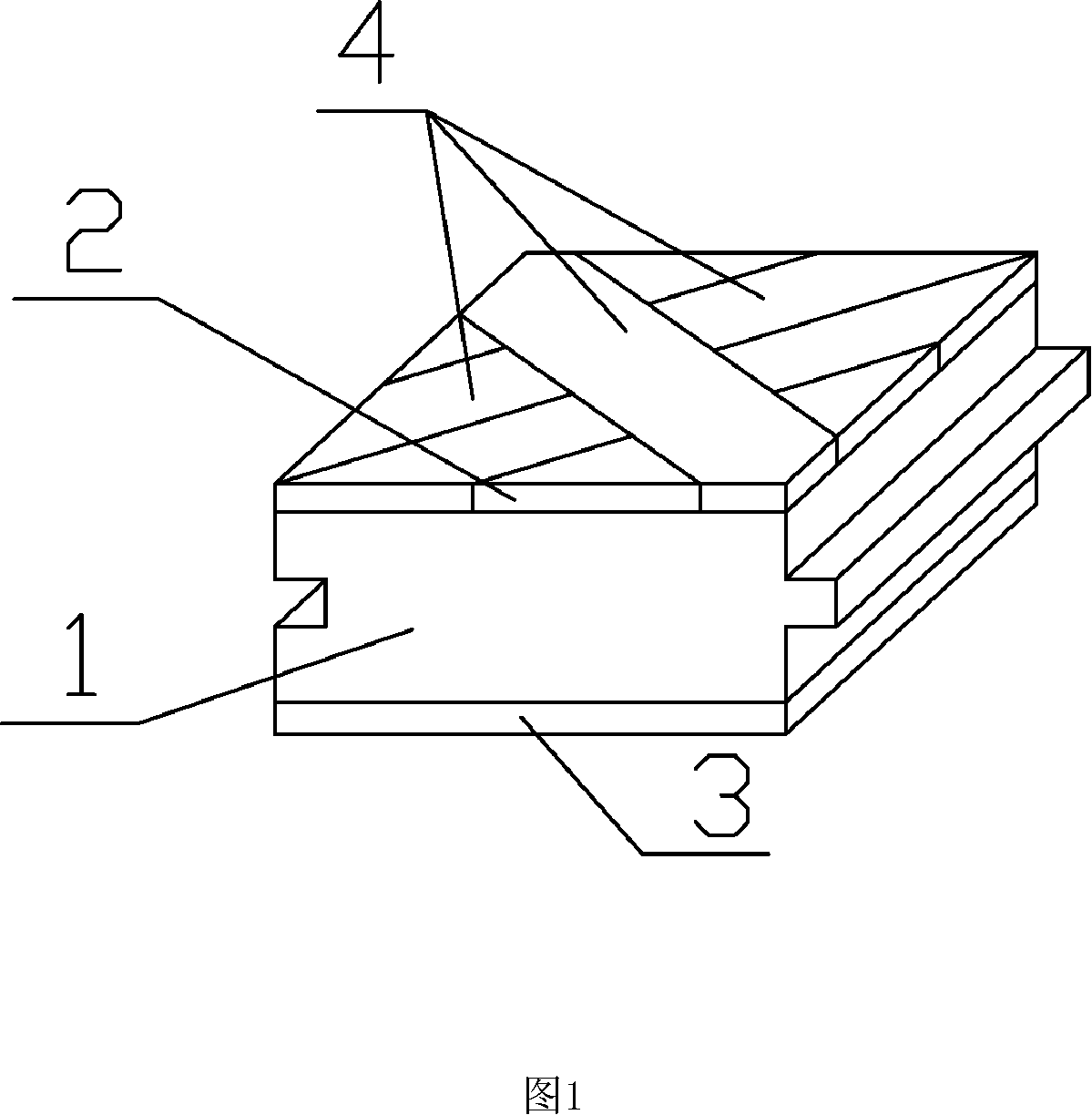

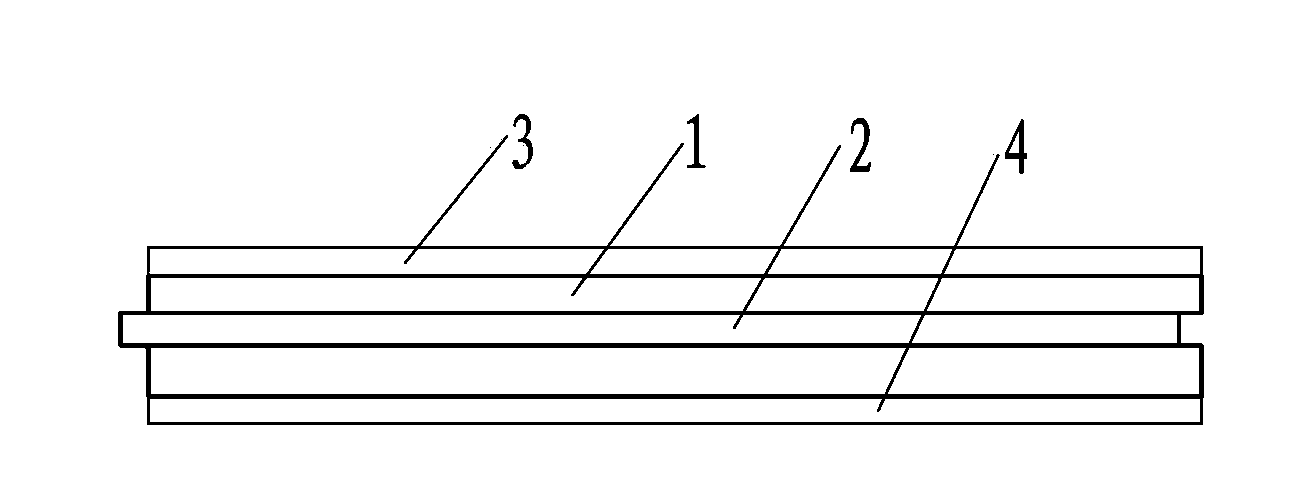

Technology for producing parquet wood composite floor and its product

InactiveCN101125435AIncrease profitImprove stabilityWood working apparatusParquetinaUtilization rate

The present invention discloses a manufacturing technique of matched wood composite floor. The method comprises grooving a substrate (1) with common technique, which comprises the following steps: a. the substrate (1), a dash board (2) and a base board (3) are coated for assembly so as to obtain A product; b. combined design and shape are done to A product by a hot-press so as to obtain B product; c. hot pressing to B product is done for molding so as to obtain C product; d. the health of C product is preserved so as to obtain D product; e. D product is trimmed for precisely sanding so as to obtain E product; f. E product is led into a paint line for painting so as to obtain the finished product. The matching structure of the present invention is rich, with low requirement of material choice, high utilization rate of material, steady state of product use, non-easy deformation, good stability between units, and good durability and aesthetic effect. The product has easy manufacturing and operation, low manufacturing cost, high production efficiency and steady quality of product; moreover, the floor has clear wood grain and ideal paint film, and is bright and smooth, clean and aesthetic.

Owner:浙江永吉木业有限公司

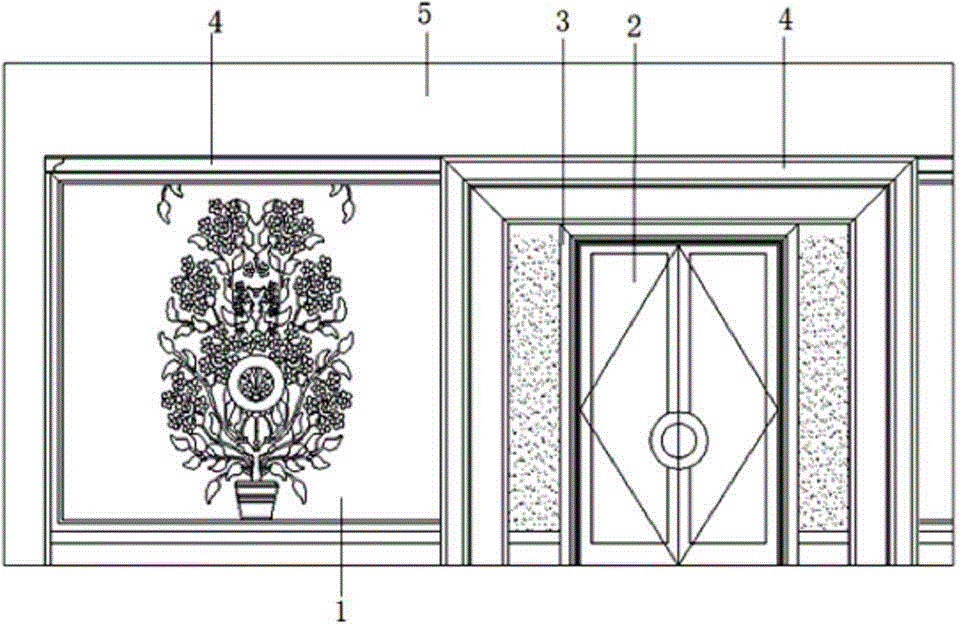

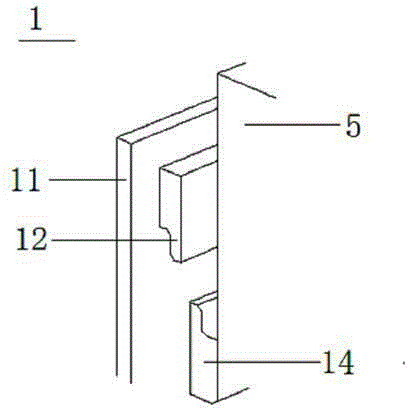

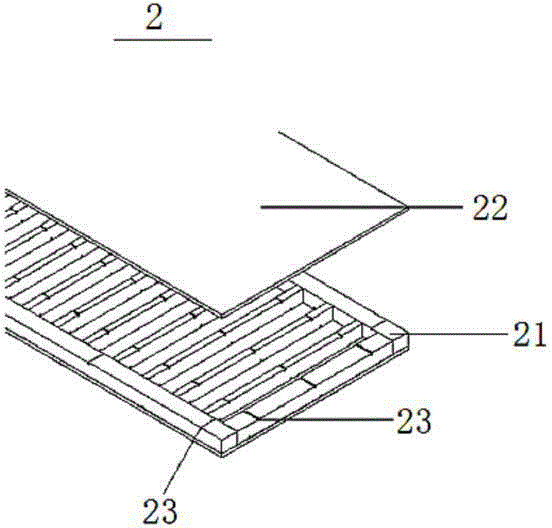

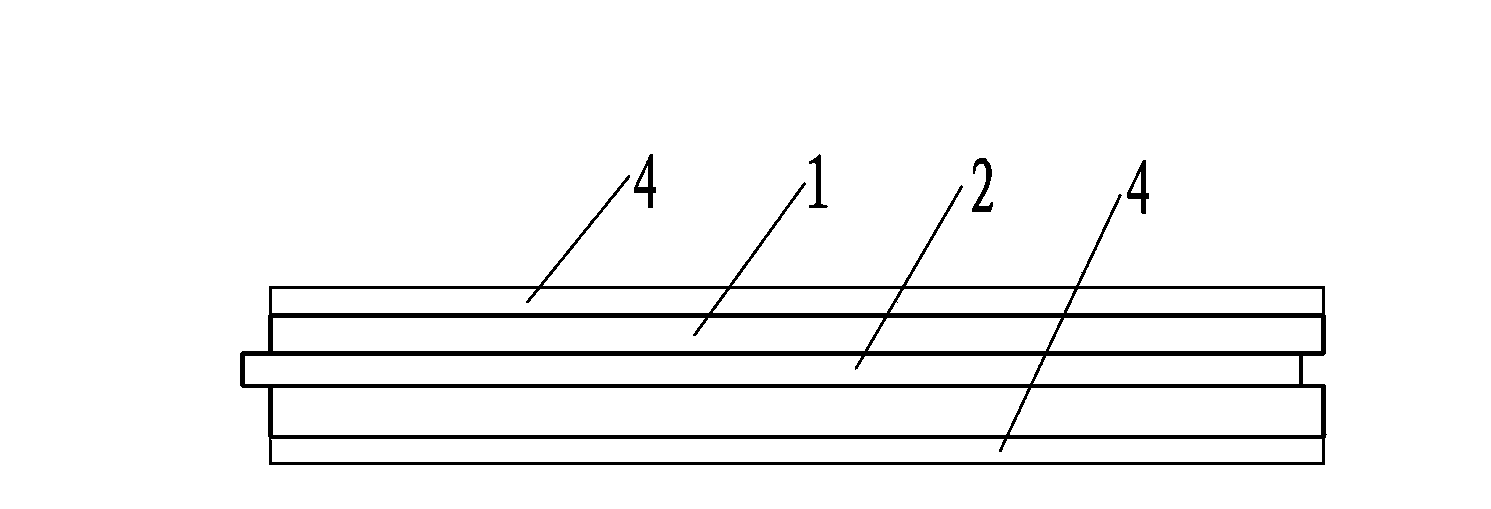

Integrated production process of fixedly-assembled furniture

InactiveCN103061461AIncreased speed of on-site installationReduce some inevitable defects of on-site assemblyCovering/liningsWindow/door framesIndustrial engineeringManufacturing engineering

An integrated production process of fixedly-assembled furniture includes first conducting accurate measurement of upper thread and elevation line according to onsite basic level, recording size on the wall face to serve as an accordance for review and onsite assembly and transmitting drawing size resources to a factory to place an order and produce the furniture after a design party, a decoration party and an owner party confirm. Various wall face veneer panels, doors, door pockets, wire frames and furniture are produced in the factory according to the drawing and are transmitted to the construction site for assembly. The process can reduce onsite construction, is less in pollution and capable of saving cost due to unified production in the factory, shortens erection time, and is stable in quality. The integral style is coordinated in unified mode.

Owner:SHANGHAI TAIYI ENTERPRISE

Process for integrally forming simulated wood grain patterns through die pressing

InactiveCN101670674AHigh degree of light junctionFeel goodDomestic articlesGlass fiberPolyester resin

The invention provides a one-off press forming process for integrally forming simulated wood grain patterns through die pressing. The process comprises: adopting an FRP (glass fiber reinforced plastics)-body die formed by piecing a plurality of block; installing a specially-made heating element in the die; allowing the temperature of the die to reach 68 DEG C; coating the the surface of an inner layer of the die with a transparent resin glue coat and forming a semi-solidified state; brushing wood grain paint (pigment, resin, curing agents and accelerators) prepared in advance on the glue coatand allowing the wood grain paint to be in a semi-solidified state at the same time; and forming auxiliary layers according to product size (auxiliary-layer materials are polyester resin, glass fiber,filling powder, flame retardant, flame-retardant powder and anti-aging agents) so as to form products.

Owner:刘健

Aqueous acrylic flame retardant coating, preparation method thereof and construction process

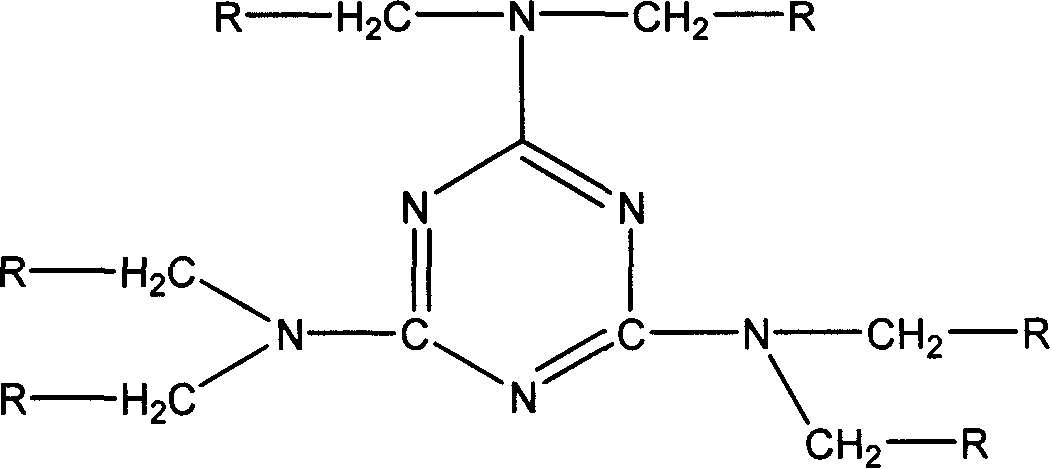

InactiveCN109251615AHigh glossWater resistantFireproof paintsLiquid surface applicatorsPre treatmentMelamine

The invention discloses an aqueous acrylic flame retardant coating. The coating comprises the following components in parts by mass: 30-50 parts of aqueous acrylic acid, 5-10 parts of ammonium polyphosphate, 10-20 parts of asbestos powder, 5-10 parts of melamine, 8-15 parts of coated mica powder, 5 to 8 parts of temperature resistant pigment, and 30 to 40 parts of deionized water. The preparationmethod comprises the following steps: S1: weighing aqueous acrylic acid, ammonium polyphosphate, asbestos powder, melamine, coated mica powder and temperature-resistant pigment to obtain a preliminarymixture; S2: grinding the preliminary mixture, adding deionized water to mix and stir the materials, and finally filtering the material with a 200-mesh screen; and S3: packaging. The construction process comprises the following steps: A1: pretreatment of a part to-be-painted; A2: preparation of the aqueous acrylic flame retardant coating, and applying the primary coating to the part to-be-painted; and A3: performing the secondary coating, wherein a coating thickness in the primary coating and the secondary coating is 80 to 120 microns.

Owner:CHONGQING QICAIHONG CHEM

Semitransparent mahogany calcined umber smell cleaning type polyurethane woodenware paint and preparation method thereof

InactiveCN104726003AAnti-scratch hasHigh hardnessPolyurea/polyurethane coatingsPigment pastesBenzeneKetone

The invention relates to a semitransparent mahogany calcined umber smell cleaning type polyurethane woodenware paint and a preparation method thereof. The paint comprises a component A and a component B according to a weight ratio of 1:0.5; the component A is composed of smell cleaning type alkyd resin, extinction powder, a dispersant, an imitation mahogany color paste, a leveling agent, an antifoaming agent, an anti-settling agent and a solvent; and the component B is a non-benzene curing agent based on TDI and HDI trimer or adduct. The semitransparent mahogany calcined umber smell cleaning type polyurethane woodenware paint prepared in the invention does not contain aromatic hydrocarbons, aldehyde, ketone or heavy metals, and can reach a smell cleaning effect 48h after a film is formed by coating the paint; the paint has the advantages of no settlement, good levelability, good handle, high scratch resistance and no ghosting in the storage process; and the paint can be coated on woodenware to realize clear and intensive wood grains and make furniture elegant, noble, natural and comfortable, adapts to modern aesthetics, is popular in the market and is loved by users. The paint can be widely used to realize surface decoration protection of woodenwares, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Environmental friendly natural color solid wood floor and machining method thereof

The invention provides an environmental friendly natural color solid wood floor. The environmental friendly natural color solid wood floor adopts original ecological solid wood floor and a bee wax layer covers the surface of the floor or a moisture proof bee wax layer covers the rear side of the floor and a brightening bee wax layer covers the front side of the floor. The environmental friendly natural color solid wood floor has the advantages of being free of paint, natural in color, tasteless, poisonous-free, smooth and moisture in hand feeling, clear in wood grain, moisture proof and free of deformation, overcoming the disadvantages that two ends or the periphery of the paint solid floor is downward buckling deformed, having bright and attractive effect as the paint floor and being environmental friendly. A machining method of the environmental friendly natural color solid wood floor has the advantages of improving the production efficiency by 80 % and reducing the production costs by 20 %.

Owner:曹玉仁

Wear-resistant wood finish paint

The invention discloses a wear-resistant wood finish paint, belonging to the technical field of paints. The wear-resistant wood finish paint is prepared from 40-50 parts of cellulose nitrate, 2-10 parts of modified rosin resin, 1-3 parts of alkyd resin, 1-3 parts of acrylic resin, 1-3 parts of amino resin, 1-3 parts of plasticizer, 5-10 parts of solvent, 1-2 parts of cosolvent, 1-3 parts of diluter and 20-40 parts of inorganic aluminum oxide. Compared with the prior art, by using the reasonable component matching, the wear-resistant wood finish paint has the advantages of high drying speed, hard paint film, high wear resistance and clear wood grains.

Owner:DRAGON FISH PAINT

A translucent chestnut red calcined amba odor-cleaning type polyurethane wood lacquer and its preparation method

InactiveCN106811097AHigh hardnessSmall steric hindrancePolyurea/polyurethane coatingsSolventChemistry

The invention relates to a translucent chestnut red calcined amba odor-clearing type polyurethane wood lacquer and a preparation method thereof. Composed of resin, matting powder, dispersant, chestnut red color paste, leveling agent, defoamer, anti-settling agent and solvent; component B is a benzene-free curing agent mainly composed of TDI, HDI trimer or adduct; The translucent chestnut red calcined amba deodorizing polyurethane wood lacquer prepared by the present invention does not contain aromatic hydrocarbons, aldehydes, ketones, and heavy metals, and achieves deodorizing effect after 48 hours of coating and film formation; and does not precipitate during storage, Good leveling, good hand feeling, high scratch resistance, no ghosting; the wood grain is clear and thorough when painted on wood, making the furniture look elegant, noble, simple and natural, giving people an elegant and comfortable feeling, and adapting to modern aesthetics , very popular with the market and customers. Widely used in wood, metal, plastic and other surface decoration and protection.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

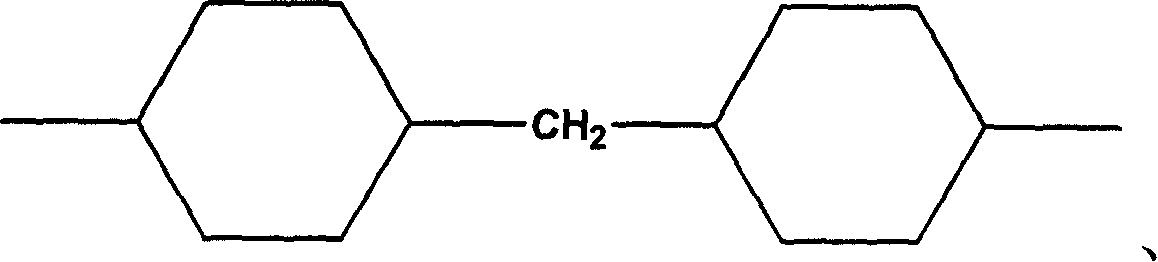

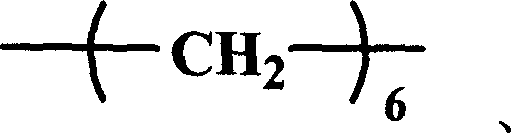

Semi-transparent light maple color calcined sienna tasteless polyurethane wood lacquer and preparation method

InactiveCN108610938AImprove the level ofFeel goodPolyurea/polyurethane coatingsAdditive ingredientExtinction

The invention relates to a semi-transparent light maple color calcined sienna tasteless polyurethane wood lacquer and a preparation method. The wood lacquer is prepared from a component A and a component B, and the weight ratio of the component A to the component B is 1:0.5; the component A is prepared from tasteless alkyd resin, extinction powder, a dispersing agent, light maple color paste, a leveling agent, a defoaming agent, an anti-settling agent and a solvent; and the component B is a benzene-free curing agent taking TDI (toluene diisocyanate) and HDI (hexamethylene diisocyanate) tripolymers or addition products as main ingredients. The prepared semi-transparent light maple color calcined sienna tasteless polyurethane wood lacquer is free of aromatic hydrocarbon, free of aldehyde ketone and free of heavy metal and can achieve a tasteless effect after being coated to form a film for 48 hours; the wood lacquer does not settle during storage, has good fluidity, good hand feeling andhigh scratch resistance, and is free of ghosting; by coating wooden ware with the wood lacquer, wood grains are clear and transparent, so that the furniture is elegant, noble, rustic and natural, brings graceful and comfortable feeling for people, adapts to the modern aesthetics, and is very popular with the market and loved by customers; and the wood lacquer can be widely applied to surface decoration and protection of wooden ware, metal, plastic and the like.

Owner:QINGDAO XIANGZHI ELECTRONICS TECH CO LTD

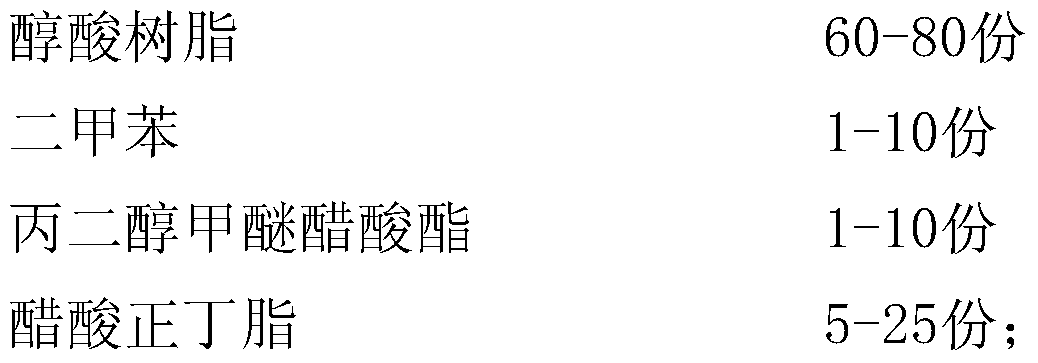

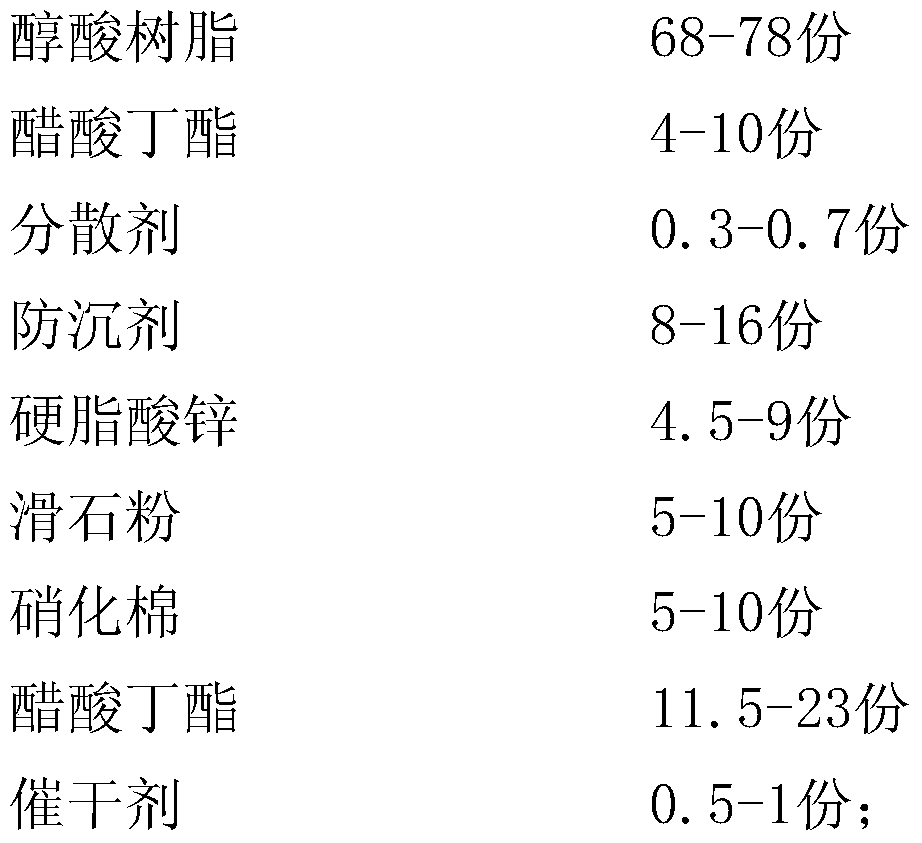

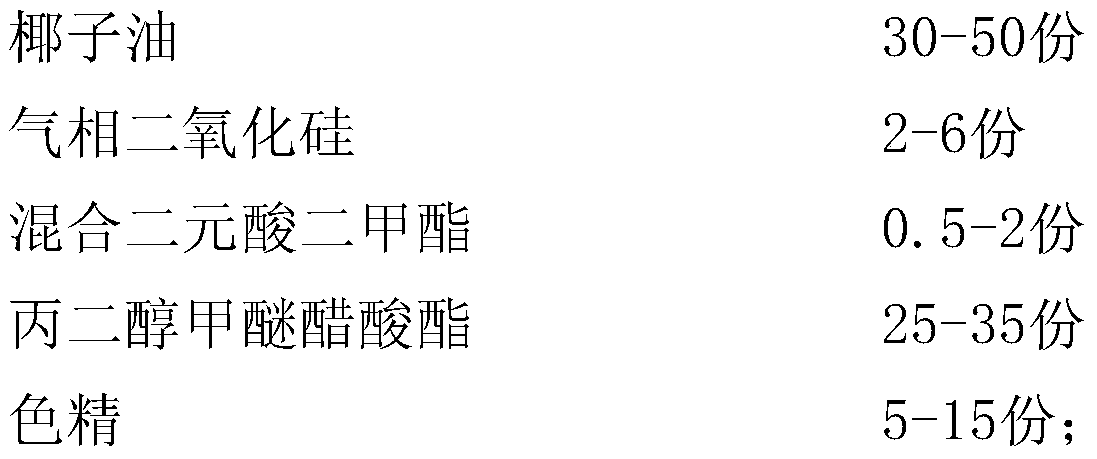

PU transparent wood combination paint and its coating process

ActiveCN104263214BExcellent color sealingPrevent muscle swellingPretreated surfacesPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The invention relates to woodware combined paint and a coating process of the combined paint, in particular to PU transparent woodware combined paint and a coating process of the combined paint, and belongs to the field of paint for furniture decoration. The PU transparent woodware combined paint comprises a PU seal primer, a PU transparent primer, a colorant and a PU transparent finishing coat, wherein the PU seal primer is prepared from a PU seal primer main agent, a curing agent I and a diluent according to the weight ratio of 1:(0.4-0.6):(0.5-0.8). The PU transparent woodware combined paint disclosed by the invention is not only excellent in color sealing, high in drying speed, fine in grain size and capable of preventing a base material from rib expanding and deforming, but also good in sanding property, and capable of protecting the base material from damage; in addition, the coating process of the PU transparent woodware combined paint disclosed by the invention not only is less in technical procedures, simple in operation, capable of reducing a lot of manpower and material resources to reduce the coating cost, but also can be used to coat the product to enable the finished product to be with clear wood grain, strong stereoscopic impression, and natural and fresh feeling.

Owner:SKSHU PAINT

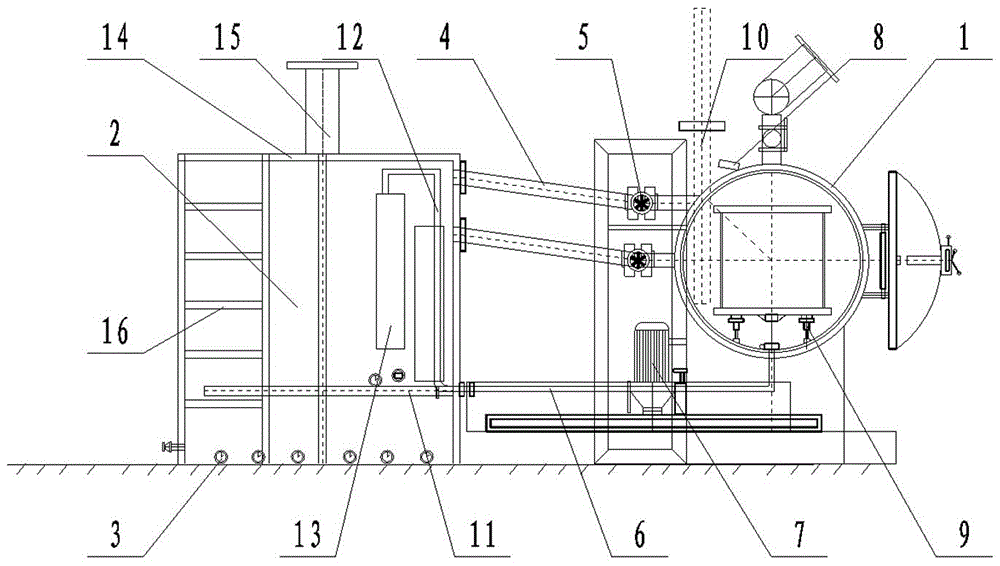

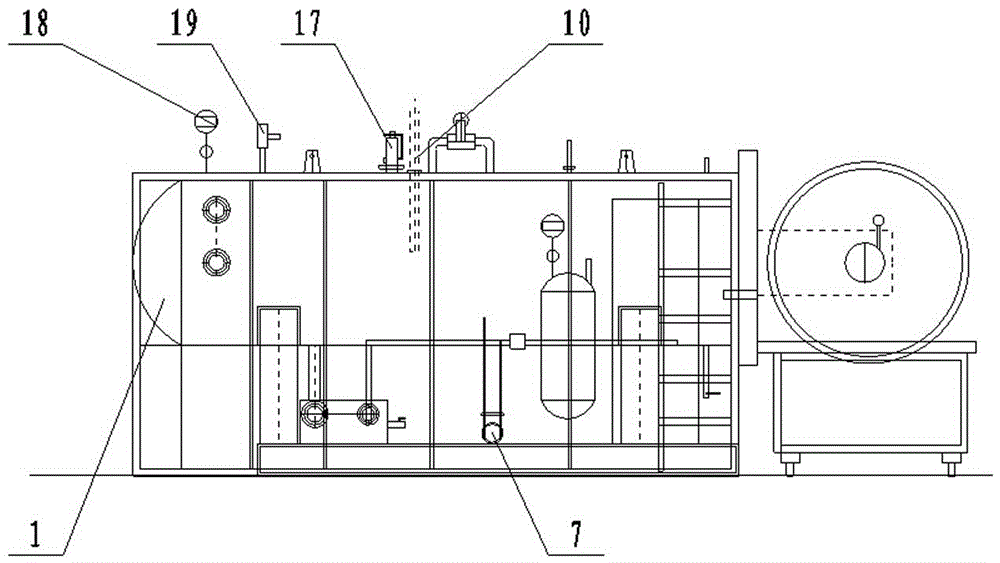

High-end wood seamless mirror treatment equipment

ActiveCN104942947BDo not change propertiesDoes not cause charringWood treatment detailsWood impregnation detailsHardnessLiquid tank

Owner:山西马峪河古建砖瓦有限公司

Translucent orange-brown calcined Sienna odorless polyurethane wood lacquer and preparation method thereof

The invention relates to a translucent orange-brown calcined Sienna odorless polyurethane wood lacquer and a preparation method thereof, wherein the translucent orange-brown calcined Sienna odorless polyurethane wood lacquer comprises a component A and a component B according to a weight ratio of 1:0.5, the component A comprises an odorless alkyd resin, matting powder, a dispersing agent, an orange-brown pigment paste, a leveling agent, an antifoaming agent, an anti-settling agent and a solvent, and the component B is a benzene-free curing agent using TDI, HDI trimer or an adduct as a main component. According to the present invention, the prepared translucent orange-brown calcined Sienna odorless polyurethane wood lacquer does not contain aromatic hydrocarbons, aldehyde ketone and heavy metals, and the odorless effect is achieved at 48 h after the wood lacquer is coated to form the film; the wood lacquer does not precipitate during the storing, and further has characteristics of goodleveling property, good hand feeling, high scratch resistance and no ghost; after the woodware is coated with the wood lacquer, the wood grain is clear and thorough, and the furniture is elegant, noble, simple and natural, can make people feel elegant and comfortable, is adapted to the modern aesthetics, and is popular in the market and is loved by customers; and the translucent orange-brown calcined Sienna odorless polyurethane wood lacquer is widely used for the surface decoration protection of woodware, metals, plastics and the like.

Owner:青岛九洲千和机械有限公司

Semi-transparent santos rose wood color raw umber flavor-clearing type polyurethane wood paint and preparation method

InactiveCN104726011AAnti-scratch hasHigh hardnessPolyurea/polyurethane coatingsPigment pastesKetoneSolvent

The invention relates to semi-transparent santos rose wood color raw umber flavor-clearing type polyurethane wood paint and a preparation method, the semi-transparent santos rose wood color raw umber flavor-clearing type polyurethane wood paint comprises a component I and a component II, the weight ratio of component I to component II is 1:0.5; the component I comprises flavor-clearing type alkyd resin, matting powder, a dispersant, santos rose wood color paste, a leveling agent, a defoaming agent an anti settling agent and a solvent; the component II is a benzene free curing agent mainly comprising TDI and HDI trimer or an addition product; the prepared semi-transparent santos rose wood color raw umber flavor-clearing type polyurethane wood paint is free of aromatic hydrocarbons, aldehydes, ketones and heavy metals, can achieve the flavor-clearing effect 48 hours after coating into a film, may not precipitate during storage, and is good in leveling property, good in hand feeling, high in scratch resistance and free of ghost image; after a wooden ware is coated with the paint, the wood grain is clear and incisive, so that the furniture is elegant, simple and natural, an elegant and comfortable feeling is given to people, and the wood paint adapts to modern aesthetics, is very popular with the market and customers, and can be widely used in surface decoration protection of wood wares, metals, plastics and the like.

Owner:UNION FOSHAN CHEM +1

Semi-transparent deep bubinga color calcined sienna flavor-clearing type polyurethane wood paint and preparation method

InactiveCN104726010AImprove the level ofFeel goodPolyurea/polyurethane coatingsPigment pastesKetoneFood flavor

The invention relates to semi-transparent deep bubinga color calcined sienna flavor-clearing type polyurethane wood paint and a preparation method, the semi-transparent deep bubinga color calcined sienna flavor-clearing type polyurethane wood paint comprises a component I and a component II, the weight ratio of component I to component II is 1:0.5; the component I comprises flavor-clearing type alkyd resin, matting powder, a dispersant, deep bubinga color paste, a leveling agent, a defoaming agent an anti settling agent and a solvent; the component II is a benzene free curing agent mainly comprising TDI and HDI trimer or an addition product; the prepared semi-transparent deep bubinga color calcined sienna flavor-clearing type polyurethane wood paint is free of aromatic hydrocarbons, aldehydes, ketones and heavy metals, can achieve the flavor-clearing effect 48 hours after coating into a film, may not precipitate during storage, and is good in leveling property, good in hand feeling, high in scratch resistance and free of ghost image; after a wooden ware is coated with the paint, the wood grain is clear and incisive, so that the furniture is elegant, simple and natural, an elegant and comfortable feeling is given to people, the wood paint adapts to modern aesthetics, is very popular with the market and customers, and can be widely used in surface decoration protection of wood wares, metals, plastics and the like.

Owner:UNION FOSHAN CHEM +1

Semitransparent walnut-color calcined Umber odorless polyurethane wood lacquer and preparation method thereof

InactiveCN104726013AImprove the level ofFeel goodPolyurea/polyurethane coatingsPigment pastesBenzenePolymer science

The invention relates to a semitransparent walnut-color calcined Umber odorless polyurethane wood lacquer and a preparation method thereof. The polyurethane wood lacquer is composed of a component A and a component B, wherein a weight ratio of the component A to the component B is 1: 0.5, the component A comprises odorless alkyd resin, matting silica, dispersant, walnut-color color paste, a leveling agent, an antifoaming agent, an anti-settling agent and a solvent, and the component B is a benzene-free curing agent mainly comprising TDI, HDI trimer or an addition product. The prepared semitransparent walnut-color calcined Umber odorless polyurethane wood lacquer does not contain aromatic hydrocarbon, aldehyde ketone and heavy metals, achieves odorless effect in 48 h after coating and film formation and has the advantages of no deposition during storage, good levelability, good hand feeling, high scratch resistance and no ghosting phenomenon; when woodenware is coated with the polyurethane wood lacquer, the woodenware has clear and penetrating wood grains, appears to be elegant, noble, plain and natural, endows people with the feelings of elegance and comfortableness, adapts to modern aesthetic views and is favored by the market and popular among customers; and the polyurethane wood lacquer is extensively applied to surface decoration and protection of woodenware, metals, plastics, etc.

Owner:UNION FOSHAN CHEM +1

Semitransparent dark red raw umber smell cleaning type polyurethane woodenware paint and preparation method thereof

InactiveCN104725993AHigh hardnessSmall steric hindrancePolyurea/polyurethane coatingsPigment pastesSolventChemistry

The invention relates to a semitransparent dark red raw umber smell cleaning type polyurethane woodenware paint and a preparation method thereof. The paint comprises a component A and a component B according to a weight ratio of 1:0.5; the component A is composed of smell cleaning type alkyd resin, extinction powder, a dispersant, a dark red color paste, a leveling agent, an antifoaming agent, an anti-settling agent and a solvent; and the component B is a non-benzene curing agent based on TDI and HDI trimer or adduct. The semitransparent dark red raw umber smell cleaning type polyurethane woodenware paint prepared in the invention does not contain aromatic hydrocarbons, aldehyde ketone or heavy metals, and can reach a smell cleaning effect 48h after a film is formed by coating the paint; the paint has the advantages of no settlement, good levelability, good handle, high scratch resistance and no ghosting in the storage process; and the paint can be coated on woodenware to realize clear and intensive wood grains and make furniture elegant, noble, natural and comfortable, adapts to modern aesthetics, is popular in the market and is loved by users. The paint can be widely used to realize surface decoration protection of woodenwares, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Semitransparent brown calcined sienna smell cleaning polyurethane woodenware paint and preparation method thereof

InactiveCN104726005AImprove the level ofFeel goodPolyurea/polyurethane coatingsPolymer scienceFirming agent

The invention relates to a semitransparent brown calcined sienna smell cleaning type polyurethane woodenware paint and a preparation method thereof. The paint comprises a component A and a component B according to a weight ratio of 1:0.5; the component A is composed of smell cleaning type alkyd resin, extinction powder, a dispersant, a brown calcined sienna color paste, a leveling agent, an antifoaming agent, an anti-settling agent and a solvent; and the component B is a non-benzene curing agent based on TDI and HDI trimer or adduct. The semitransparent brown calcined sienna smell cleaning type polyurethane woodenware paint prepared in the invention does not contain aromatic hydrocarbons, aldehyde ketone or heavy metals, and can reach a smell cleaning effect 48h after a film is formed by coating the paint; the paint has the advantages of no settlement, good levelability, good handle, high scratch resistance and no ghosting in the storage process; and the paint can be coated on woodenware to realize clear and intensive wood grains and make furniture elegant, noble, natural and comfortable, adapts to modern aesthetics, is popular in the market and is loved by users. The paint can be widely used to realize surface decoration protection of woodenwares, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Semi-transparent amber yellow raw umber tasteless polyurethane wood lacquer and preparation method

The invention relates to a semi-transparent amber yellow raw umber tasteless polyurethane wood lacquer and a preparation method. The wood lacquer is prepared from a component A and a component B, andthe weight ratio of the component A to the component B is 1:0.5; the component A is prepared from tasteless alkyd resin, extinction powder, a dispersing agent, amber yellow color paste, a leveling agent, a defoaming agent, an anti-settling agent and a solvent; and the component B is a benzene-free curing agent taking TDI (toluene diisocyanate) and HDI (hexamethylene diisocyanate) tripolymers or addition products as main ingredients. The prepared semi-transparent amber yellow raw umber tasteless polyurethane wood lacquer is free of aromatic hydrocarbon, free of aldehyde ketone and free of heavymetal and can achieve a tasteless effect after being coated to form a film for 48 hours; the wood lacquer does not settle during storage, has good leveling property, good hand feeling and high scratch resistance, and is free of ghosting; by coating wooden ware with the wood lacquer, wood grains are clear and transparent, so that the furniture is elegant, noble, rustic and natural, brings gracefuland comfortable feeling for people, adapts to the modern aesthetics, and is very popular with the market and loved by customers; and the wood lacquer can be widely applied to surface decoration and protection of wooden ware, metal, plastic and the like.

Owner:QINGDAO XIANGZHI ELECTRONICS TECH CO LTD

Semi-transparent madam red raw sienna flavor-clearing type polyurethane wood paint and preparation method

InactiveCN104725996AAnti-scratch hasHigh hardnessPolyurea/polyurethane coatingsPigment pastesKetoneSolvent

The invention relates to semi-transparent madam red raw sienna flavor-clearing type polyurethane wood paint and a preparation method, the semi-transparent madam red raw sienna flavor-clearing type polyurethane wood paint comprises a component I and a component II, the weight ratio of component I to component II is 1:0.5; the component I comprises flavor-clearing type alkyd resin, matting powder, a dispersant, madam red color paste, a leveling agent, a defoaming agent an anti settling agent and a solvent; the component II is a benzene free curing agent mainly comprising TDI and HDI trimer or an addition product; the prepared semi-transparent madam red raw sienna flavor-clearing type polyurethane wood paint is free of aromatic hydrocarbons, aldehydes, ketones and heavy metals, can achieve the flavor-clearing effect 48 hours after coating into a film, may not precipitate during storage, and is good in leveling property, good in hand feeling, high in scratch resistance and free of ghost image; after a wooden ware is coated with the paint, the wood grain is clear and incisive, so that the furniture is elegant, simple and natural, an elegant and comfortable feeling is given to people, and the wood paint adapts to modern aesthetics, is very popular with the market and customers, and can be widely used in surface decoration protection of wood wares, metals, plastics and the like.

Owner:UNION FOSHAN CHEM +1

Semitransparent Thai teak color raw umber air purification type polyurethane wood paint and preparation method thereof

InactiveCN104725999AImprove the level ofFeel goodPolyurea/polyurethane coatingsPigment pastesKetoneSolvent

The invention relates to a semitransparent Thai teak color raw umber air purification type polyurethane wood paint and a preparation method thereof. The polyurethane wood paint is composed of a component A and a component B in a weight ratio of 1:0.5. The component A consists of air purification type alkyd resin, matting powder, a dispersant, a Thai teak color paste, a leveling agent, a defoaming agent, an anti-settling agent, and a solvent. The component B is a benzene-free curing agent based on TDI, HDI trimer or adduct. The semitransparent Thai teak color raw umber air purification type polyurethane wood paint prepared by the invention does not contain aromatic hydrocarbon, aldehyde ketone or heavy metal, can reach the air purification effect after coating into a film, and during storage, has the characteristics of no precipitate, good leveling property, good hand feel, high scratch resistance, and no ghosting. After coating a wooden ware with the paint, the wood grains are clear and thorough, so that the furniture looks elegant and noble, plain and natural, gives people graceful and comfortable feel, and adapts to modern aesthetic view, thus being very popular with the market and customers. The semitransparent Thai teak color raw umber air purification type polyurethane wood paint provided by the invention is widely used for surface decoration and protection of wooden wares, metals, plastics and the like.

Owner:UNION FOSHAN CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com