PU transparent wood combination paint and its coating process

A coating process and technology of transparent primer, applied in the field of furniture decoration paint, can solve the problems of high coating cost, slow drying speed of the surface of the paint film, no three-dimensional effect, etc. Cost, the effect of reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A PU transparent wood combination paint, which comprises PU sealing primer, PU transparent primer, colorant and PU transparent topcoat;

[0070] Wherein, the PU sealing primer is prepared by the PU sealing primer main agent, curing agent I and diluent in a weight ratio of 1:0.5:0.65;

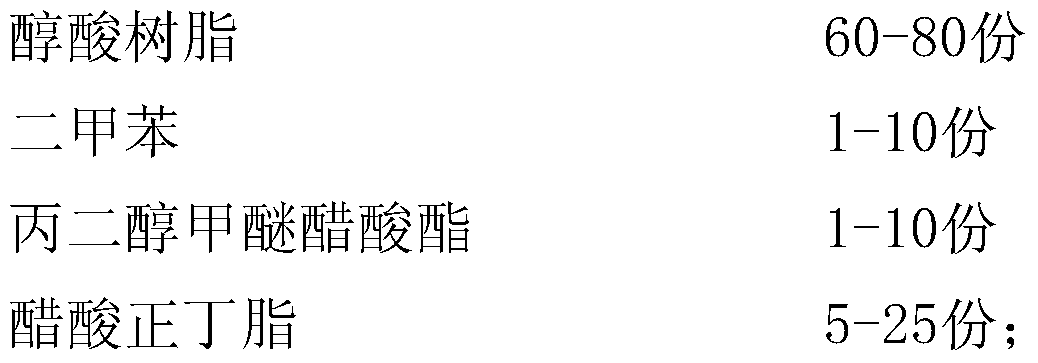

[0071] Wherein, the main agent of the PU sealing primer is prepared from the following raw materials according to the following weight ratio:

[0072]

[0073] The PU transparent primer is prepared by the PU transparent primer main agent, curing agent I and diluent in a weight ratio of 1:0.9:0.7;

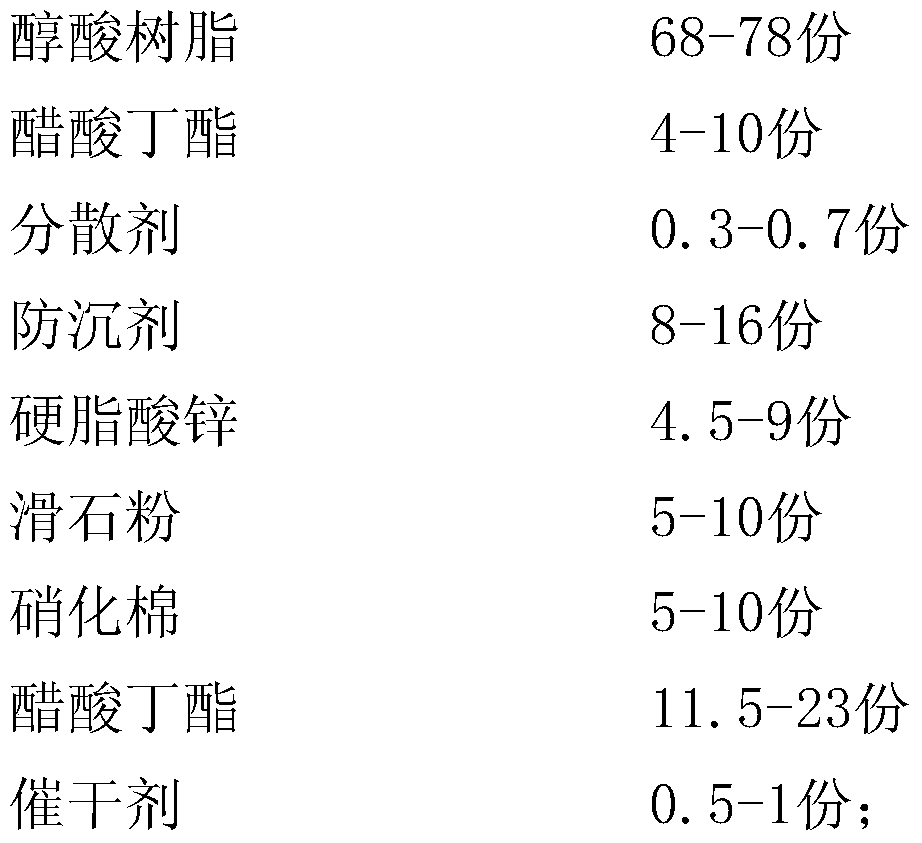

[0074] Wherein, the main agent of the PU transparent primer is prepared from the following raw materials according to the following weight ratio:

[0075]

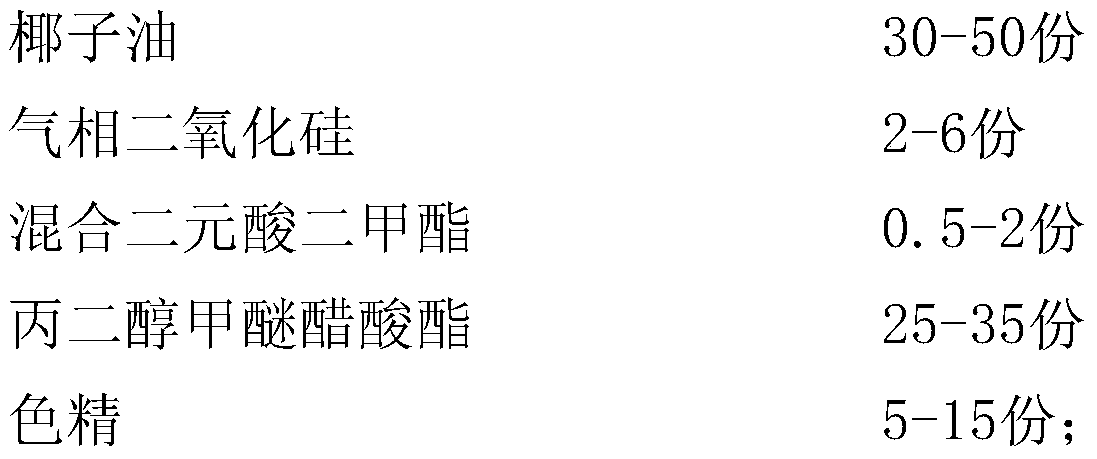

[0076] The coloring agent is prepared from the following raw materials according to the following weight ratio:

[0077]

[0078] The PU transparent topcoat is prepared from the main agent of the PU transparent topcoat, curing ag...

Embodiment 2

[0112] A PU transparent wood combination paint, which comprises PU sealing primer, PU transparent primer, colorant and PU transparent topcoat;

[0113] Wherein, the PU sealing primer is prepared by the PU sealing primer main agent, curing agent I and diluent in a weight ratio of 1:0.4:0.5;

[0114] Wherein, the main agent of the PU sealing primer is prepared from the following raw materials according to the following weight ratio:

[0115]

[0116] The PU transparent primer is prepared by the PU transparent primer main agent, curing agent I and diluent in a weight ratio of 1:0.8:0.6;

[0117] Wherein, the main agent of the PU transparent primer is prepared from the following raw materials according to the following weight ratio:

[0118]

[0119] The coloring agent is prepared from the following raw materials according to the following weight ratio:

[0120]

[0121] The PU transparent topcoat is prepared by the main agent of the PU transparent topcoat, curing agent...

Embodiment 3

[0155] A PU transparent wood combination paint, which comprises PU sealing primer, PU transparent primer, colorant and PU transparent topcoat;

[0156] Wherein, the PU sealing primer is prepared by the PU sealing primer main agent, curing agent I and diluent in a weight ratio of 1:0.6:0.8;

[0157] Wherein, the main agent of the PU sealing primer is prepared from the following raw materials according to the following weight ratio:

[0158]

[0159] The PU transparent primer is prepared by the PU transparent primer main agent, curing agent I and diluent in a weight ratio of 1:1:0.8;

[0160] Wherein, the main agent of the PU transparent primer is prepared from the following raw materials according to the following weight ratio:

[0161]

[0162] The coloring agent is prepared from the following raw materials according to the following weight ratio:

[0163]

[0164] The PU transparent topcoat is prepared by the PU transparent topcoat main agent, curing agent II and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com