A kind of water-based wood sealing primer and preparation method thereof

A sealing primer, water-based technology, applied in the field of architectural decoration coatings, can solve problems such as unreachable, and achieve the effects of fast drying speed, good sandability and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

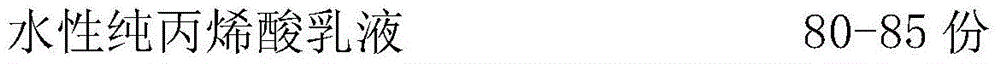

[0036] A water-based wood sealing primer prepared from the following raw materials in the following weight ratio:

[0037]

[0038] The preparation method of the water-based wood sealing primer includes the following steps in sequence:

[0039] Put 80 parts of the water-based acrylic emulsion into the dispersing tank, and then start the disperser to adjust the speed to 1000 rpm. At this speed, first add 6.8 parts of film-forming auxiliary, 0.4 parts of water-based wetting and leveling agent and 10.5 parts of water. After the addition, maintain the speed of the disperser and continue to disperse for 15 minutes until the paint is uniform.

Embodiment 1-2

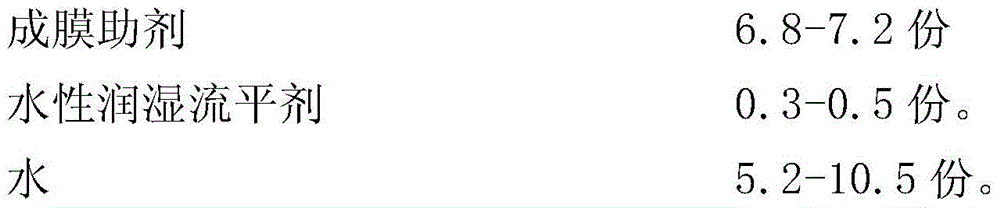

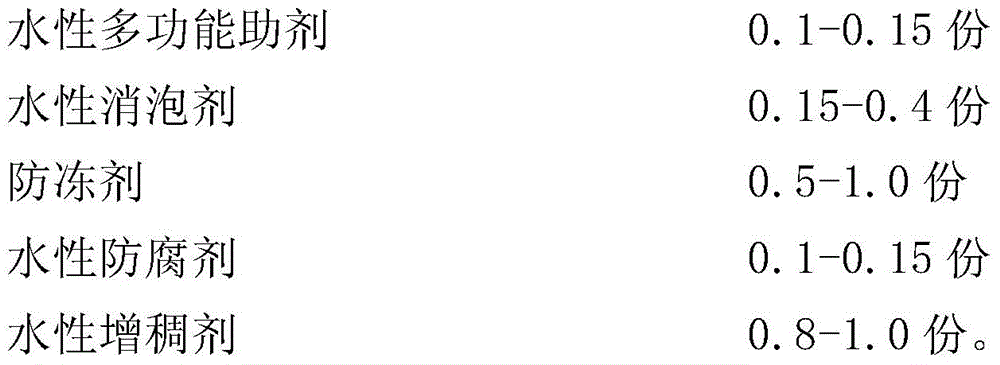

[0041] A water-based wood sealing primer prepared from the following raw materials in the following weight ratio:

[0042]

[0043] The preparation method of the water-based wood sealing primer includes the following steps in sequence:

[0044] Put 85 parts of the water-based acrylic emulsion into the dispersing tank, and then start the disperser to adjust the speed to 1000 rpm. At this speed, add 7.2 parts of the film forming aid, 0.3 parts of the water-based wetting and leveling agent, and 5.2 parts of water. After the addition, maintain the speed of the disperser and continue to disperse for 25 minutes until the paint is uniform.

Embodiment 1-3

[0046] A water-based wood sealing primer prepared from the following raw materials in the following weight ratio:

[0047]

[0048] The preparation method of the water-based wood sealing primer includes the following steps in sequence:

[0049] Put 83 parts of the water-based acrylic emulsion into the dispersing tank, then start the disperser to adjust the speed to 1100 rpm. At this speed, add 7.0 parts of the film-forming auxiliary, 0.4 parts of the water-based wetting and leveling agent, and 7.65 parts of water. After the addition, maintain the speed of the disperser and continue to disperse for 20 minutes until the paint is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com