Oily brush-off agent as well as preparation method and application thereof

A color-wiping, oil-based technology, applied in coatings and other directions, can solve the problems of paint and workload waste, monotonous polyurethane coatings, etc., to achieve the effect of simple construction, clear wood grain, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2、 comparative example 1-5

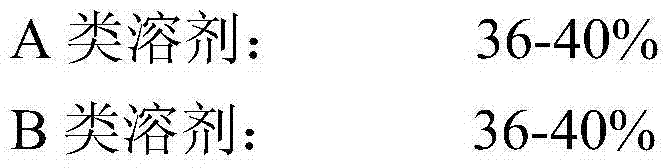

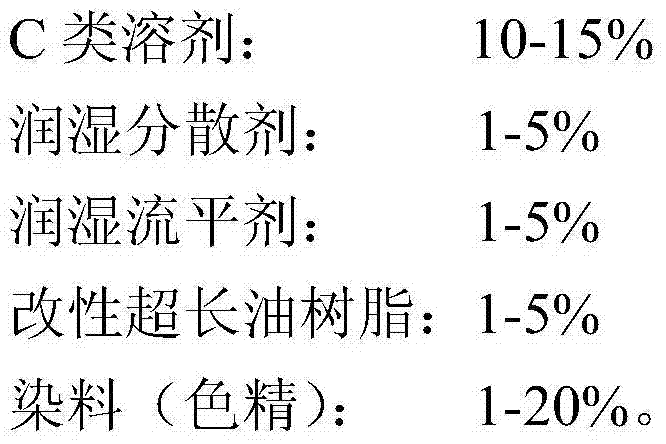

[0033] The raw material formulations of the oil-based rubbing treasures of Examples 1-2 and Comparative Examples 1-5 are shown in Table 1, and the preparation method comprises the following steps:

[0034] Mix and stir the three types of solvents A, B, and C; then add wetting and dispersing agent and wetting and leveling agent, and stir slowly (500-600r / min) for 5-10min; then add modified super long oleoresin, slowly (500-600r / min) stirring for 5-10min; finally add the color essence and slowly (500-600r / min) stir for 5-10min to obtain the oily color rubbing treasure of the present invention.

[0035] The oily rubbing treasure that embodiment and comparative example make is used for wooden furniture coloring, comprises the following steps:

[0036] The first step: wood, board (furniture white body) grinding;

[0037] Step 2: Apply PU primer on the wood and board, and dry the PU primer thoroughly (more than 24 hours);

[0038] The 3rd step: adopt spraying, brushing, roller coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com