High-end wood seamless mirror treatment equipment

A mirror treatment and wood technology, applied in wood treatment, wood treatment details, impregnated wood, etc., can solve problems such as shrinkage, dryness and brittleness, surface cracking and deformation, etc., to achieve clear wood grain, prevent wet swelling and dry shrinkage, and eliminate The effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

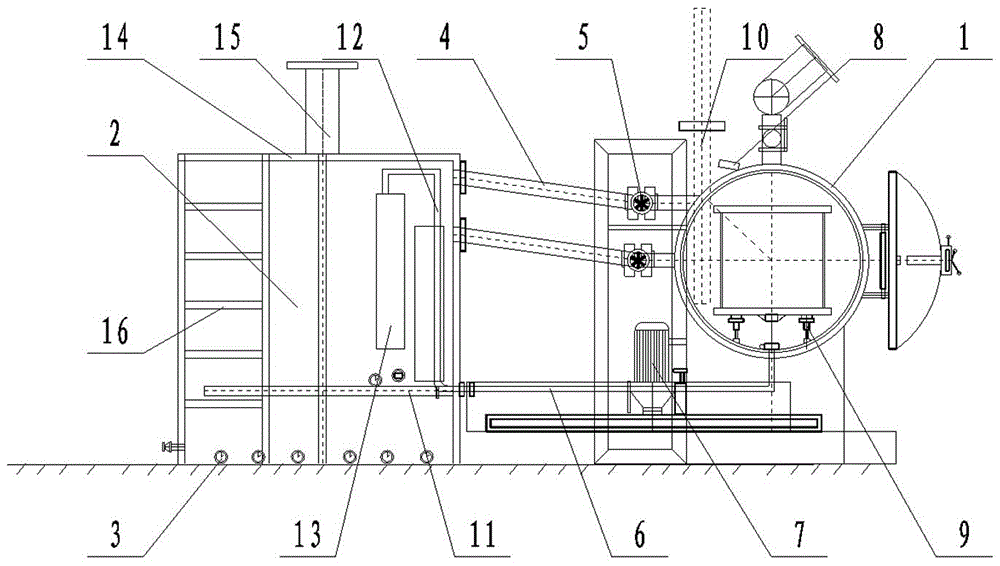

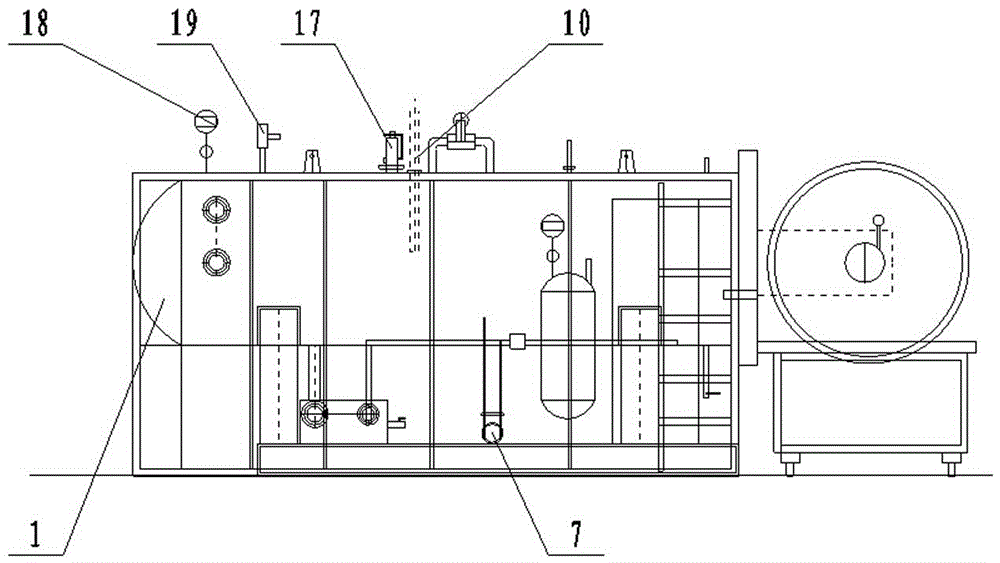

[0015] High-end wood seamless mirror treatment equipment, including horizontal wood tank 1 and columnar liquid tank 2, the bottom of columnar liquid tank 2 is provided with heating pipe 3, between the upper part of the side wall of horizontal wood tank 1 and the upper part of the side wall of columnar liquid tank 2 A liquid inlet pipe 4 communicating with the two is provided, and a gate valve 5 is provided on the liquid inlet pipe 4, and a liquid return pipe communicating with the two is provided between the bottom of the horizontal wood tank 1 and the lower part of the side wall of the columnar liquid tank 2 6. A circulation pump is provided on the liquid return pipe 6, a vacuum pump 7 communicating with it is provided on the horizontal wood tank 1 and an exhaust pipe 8 located on the upper part of the horizontal wood tank 1 and distributed obliquely upward, and the horizontal wood tank 1 is provided with a There is a slide rail 9 located at its bottom, and a liquid level tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com