Construction method of fair-faced concrete wall with wood grain finish

A technology of fair-faced concrete and construction methods, which is applied to the processing of building materials, formwork/formwork/work frame, and on-site preparation of building components. It can solve the problems of high comprehensive cost, rough concrete surface, and short service life. Achieve the effect of clear wood grain and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For the benefit of the understanding of the construction method of the present invention, below in conjunction with accompanying drawing formula is described.

[0019] The construction method of clear-faced concrete with wood grain finish of the present invention comprises the following steps:

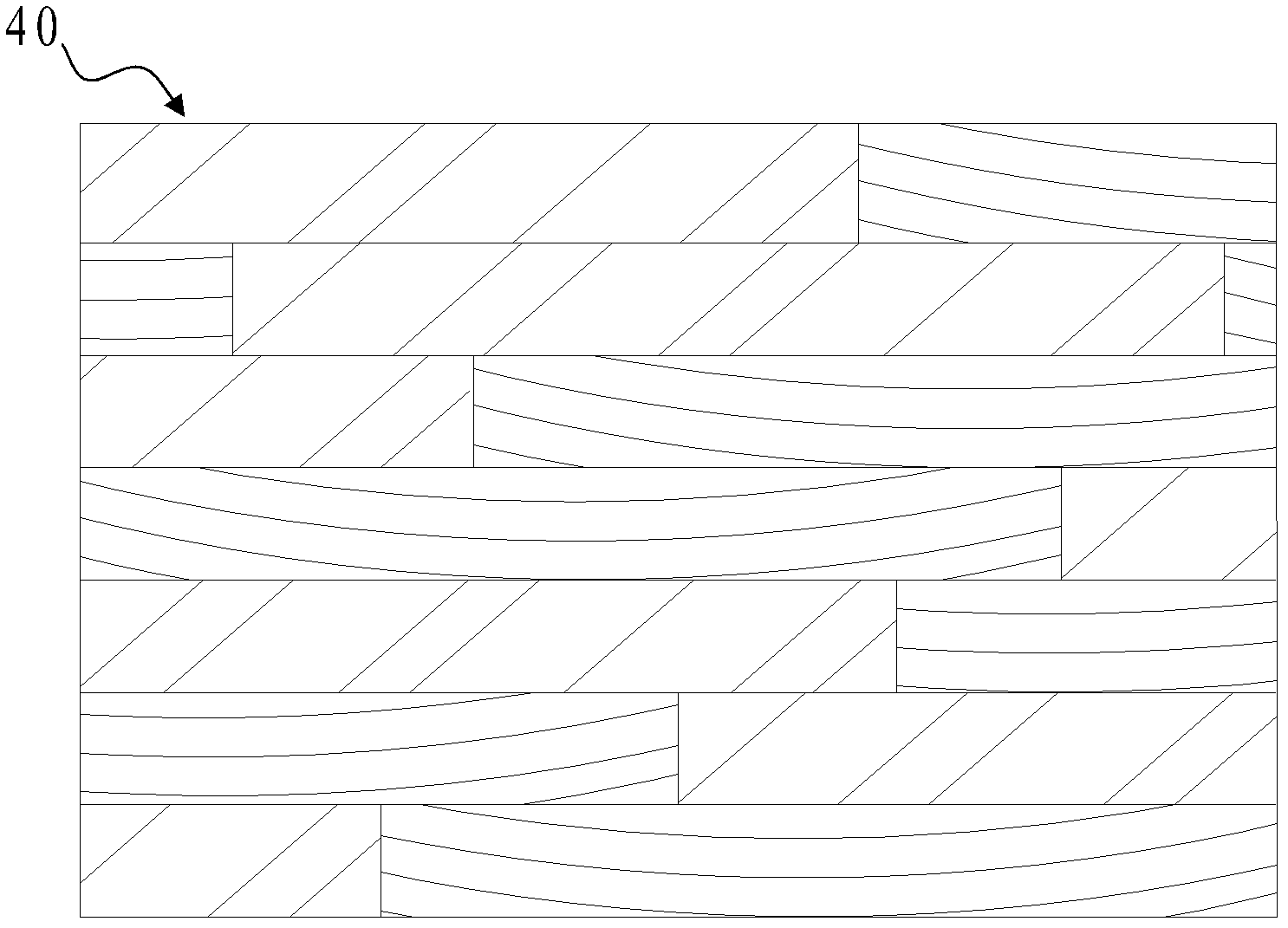

[0020] (1) Cut pine logs (or other logs with various wood grains and beautiful effects) into veneers to extract the natural wood grain effect of pine logs;

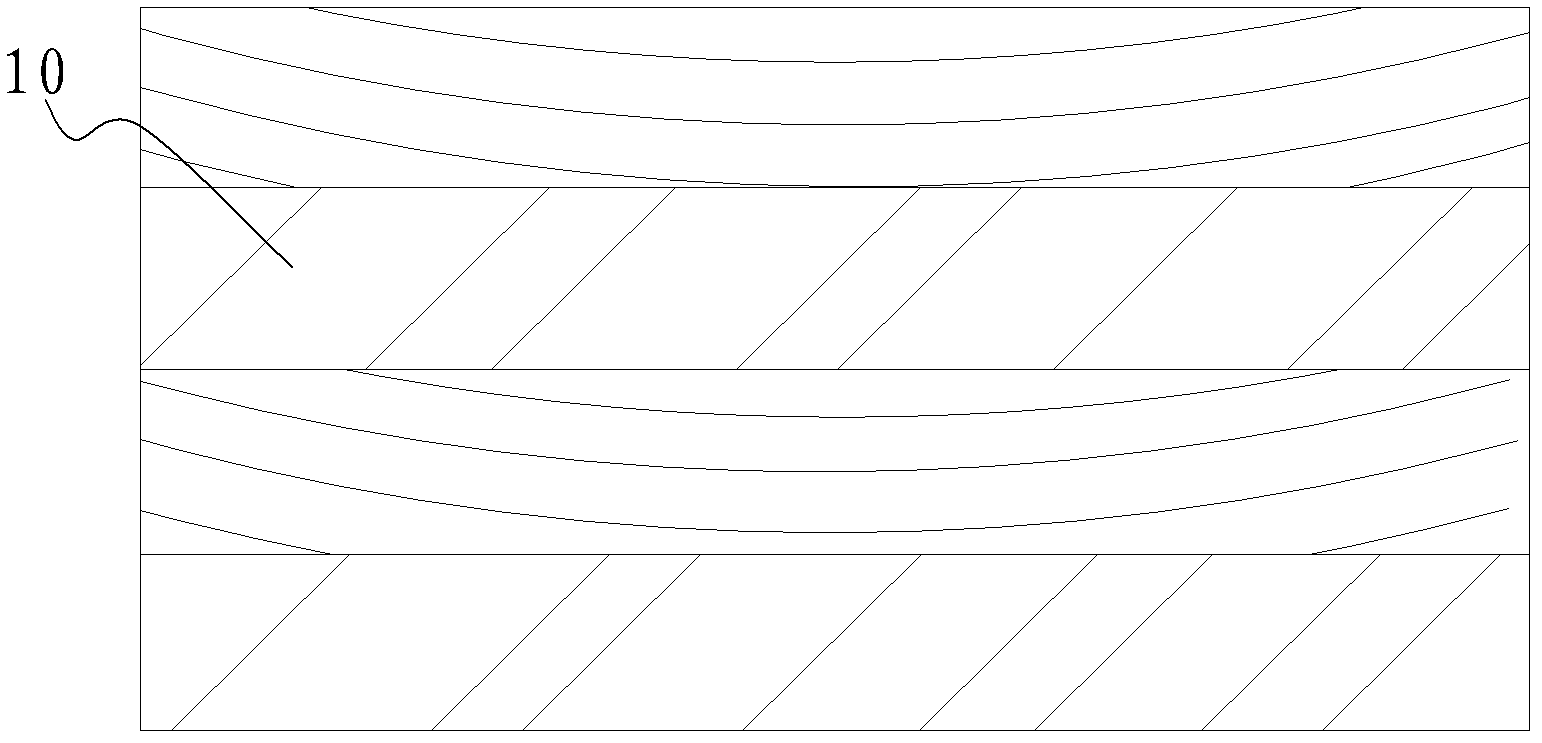

[0021] (2) scan the wood grain effect of the sylvestris sylvestris log to the computer with computer scanning technology, then adopt the engraving technology to engrave the wood grain effect of the sylvestris sylvestris log into a steel mold, and press it with a steel mold to form a high-density board 10 (see figure 1 );

[0022] (3) The high-density board 10 produced by pressing is subjected to multi-layer waxing and waterproof treatment, and finally forms a template with a wood grain effect;

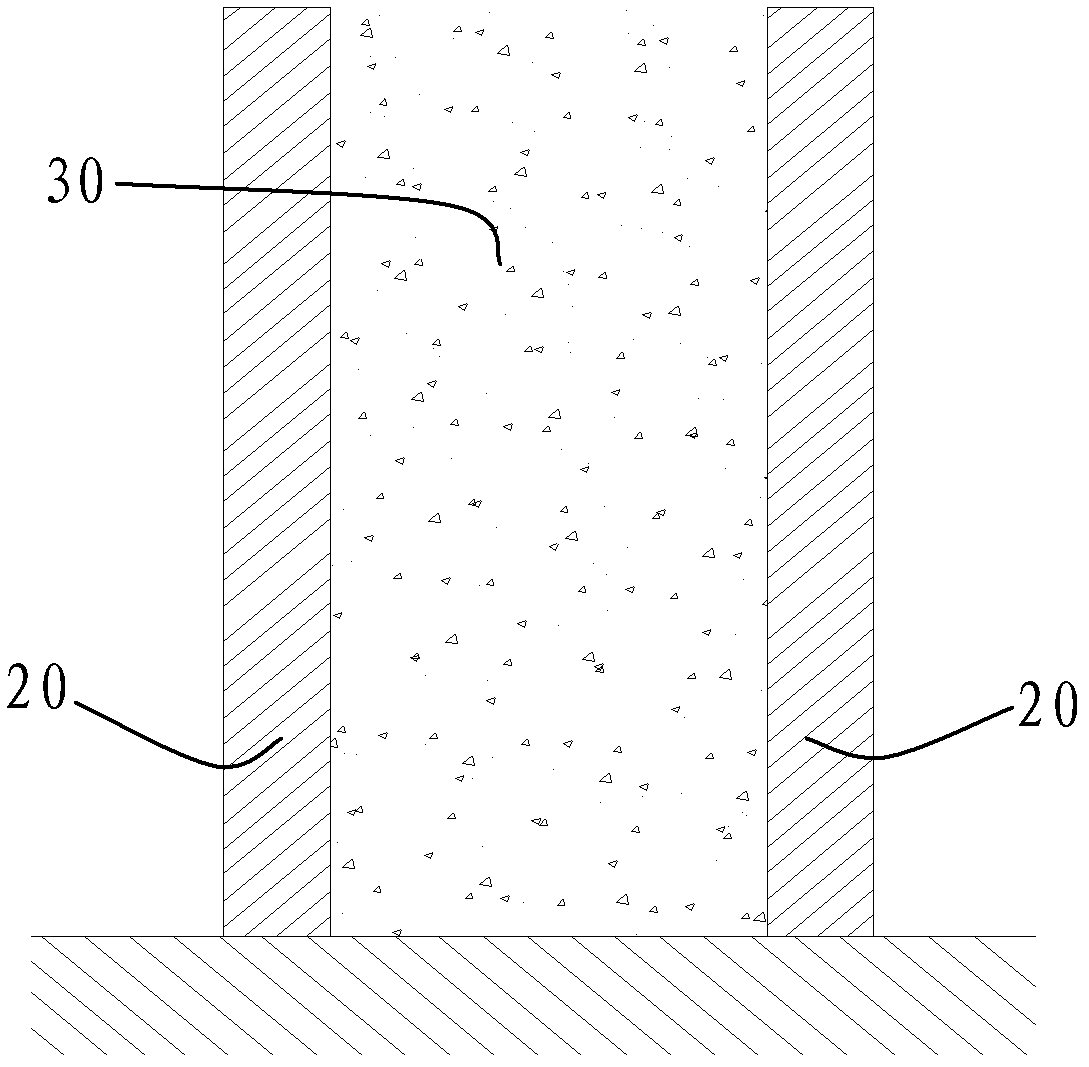

[0023] (4) form a pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com