Environmental friendly natural color solid wood floor and machining method thereof

A technology of solid wood floor and processing method, applied in the direction of floor, building, building structure, etc., can solve the problems of polluting the environment, cost, containing benzene poison, etc., and achieve the effect of improving production efficiency, clear wood grain, and overcoming warpage and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

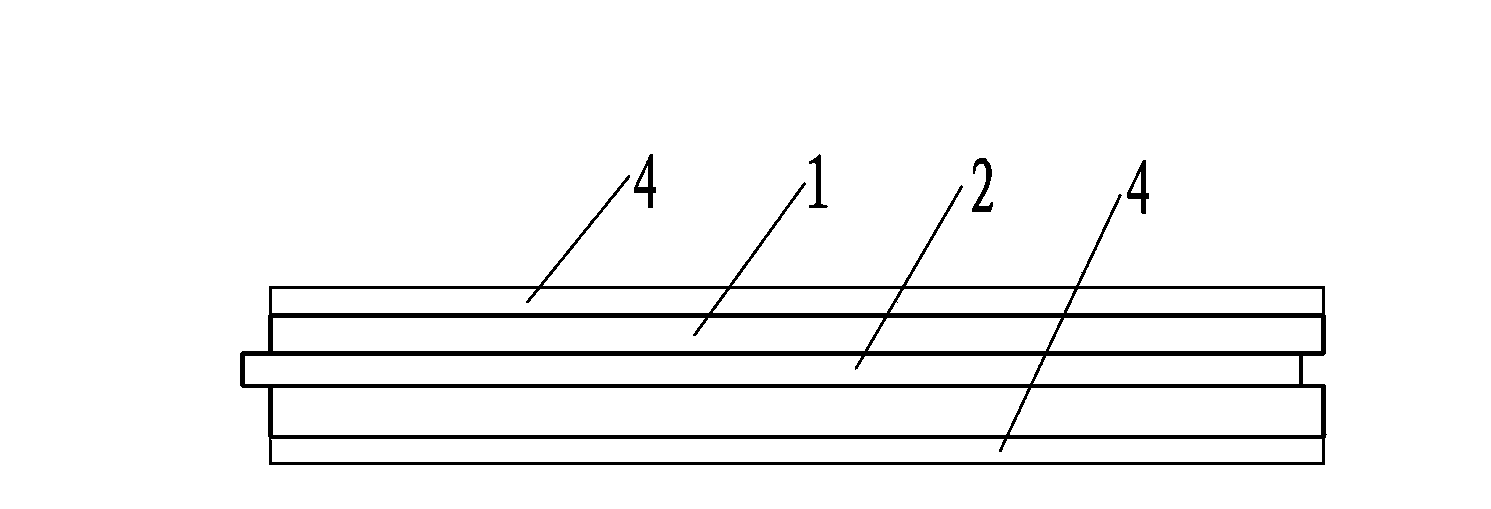

[0033] Example 1 as figure 1 As shown, an environment-friendly natural color solid wood floor adopts the original ecological solid wood floor 1, slots the tenon 2 on the solid wood floor 1 to form the slab, and then coats the surface (front and back) of the floor with a beeswax layer 4.

[0034] The processing method of this kind of environment-friendly natural color solid wood floor comprises the following steps:

[0035] 1) Sawing and cutting: Saw the original ecological solid wood according to the size requirements, and then cut;

[0036] 2) Material selection: select the available sheet materials in the floor substrate;

[0037] 3) Drying: remove excess water;

[0038] 4) Four-sided planing: determine the width and thickness dimensions;

[0039] 5) Forming: slotting, tenon making, slab forming;

[0040] 6) Sanding: fine sanding with fixed thickness;

[0041] 7) Polishing: Polishing with solid polishing paste;

[0042] 8) Surface heating of the slab: the surface heat...

Embodiment 2

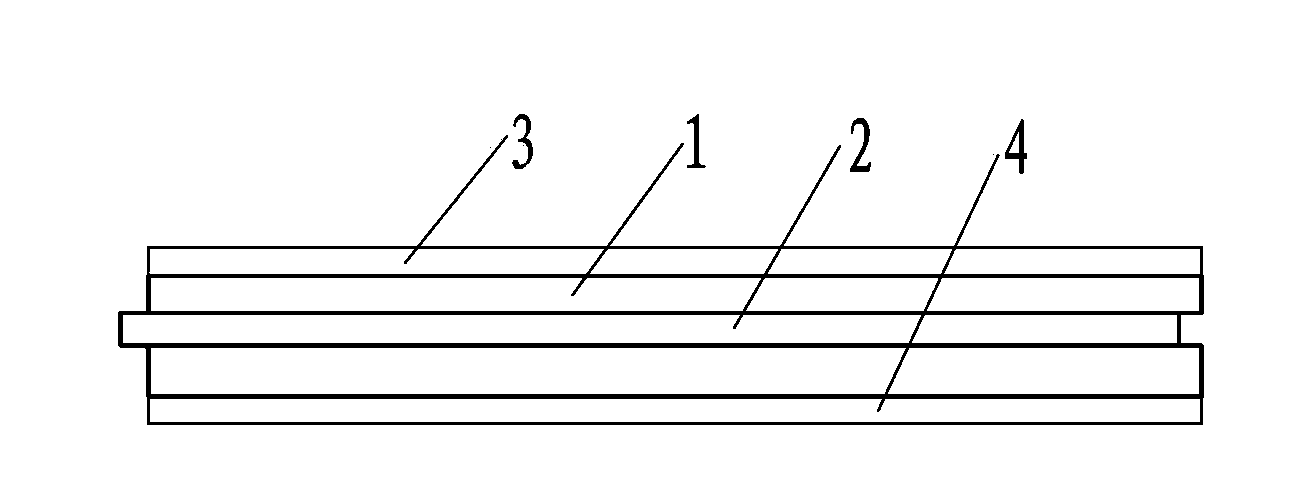

[0047] Example 2 as figure 2 As shown, another embodiment of an environmentally friendly natural color solid wood floor adopts the original ecological solid wood floor 1, slots the tenon 2 on the solid wood floor 1 to form the slab, and then the floor 1 is coated with a moisture-proof honey bee on the reverse side. Wax layer 4, the floor 1 is coated on the front side with a layer 3 of beeswax for brightening.

[0048] The processing method of this kind of environment-friendly natural color solid wood floor comprises the following steps:

[0049] 1) Sawing and cutting: Saw the original ecological solid wood according to the size requirements, and then cut;

[0050] 2) Material selection: select the available sheet materials in the floor substrate;

[0051] 3) Drying: remove excess water;

[0052] 4) Four-sided planing: determine the width and thickness dimensions;

[0053] 5) Forming: slotting, tenon making, slab forming;

[0054] 6) Sanding: fine sanding with fixed thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com