Technology for producing parquet wood composite floor and its product

A technology of solid wood composite flooring and production technology, which is applied in the direction of wood processing equipment and manufacturing tools, etc., which can solve the problems of unusable leftovers of unit wood, easy cracks in mosaic units, durability and aesthetic limitations, etc., to achieve easy implementation, Rich mosaic structure, good durability and aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

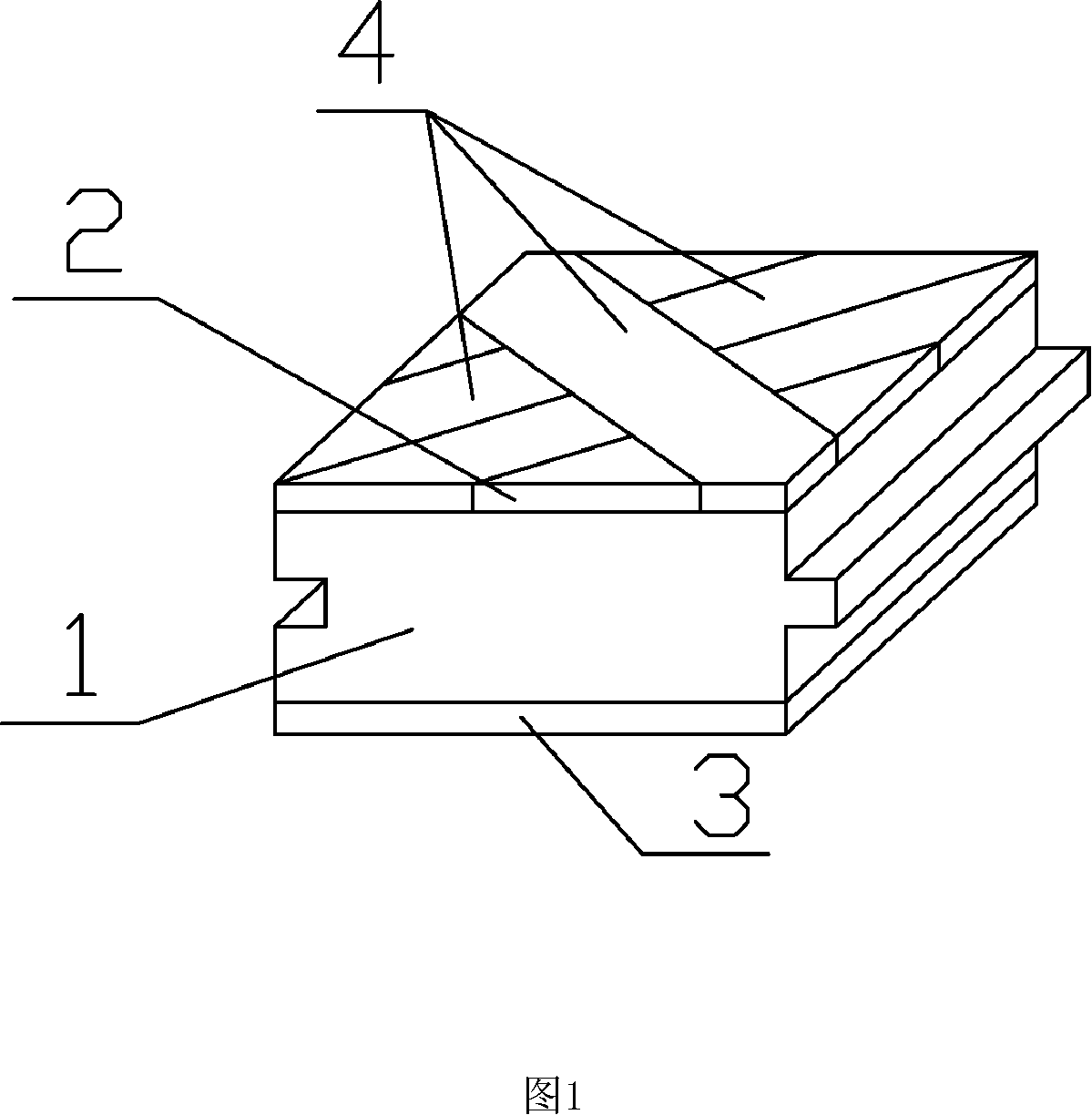

[0018] Embodiment 1 of the present invention: the production process of parquet solid wood composite flooring, it comprises that base material 1 is grooved with conventional process, comprises the following steps: material is the base material 1 of eucalyptus miscellaneous, material is the surface plate 2 of technical wood After gluing with the bottom plate 3 made of miscellaneous wood, the blank is assembled to obtain product A; the product A is mosaiced and shaped by a hot press to obtain product B; tons, the hot-pressing time is 8 minutes, and the hot-pressing temperature is 120°C to obtain product C; the product C is subjected to health preservation for 7 days to obtain product D; the edge of product D is finely sanded to obtain product E ; Import the E product into the paint line for UV lacquering processing to obtain finished products.

[0019] The structure of parquet solid wood composite flooring in this example is shown in Figure 1, and it comprises base material 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com