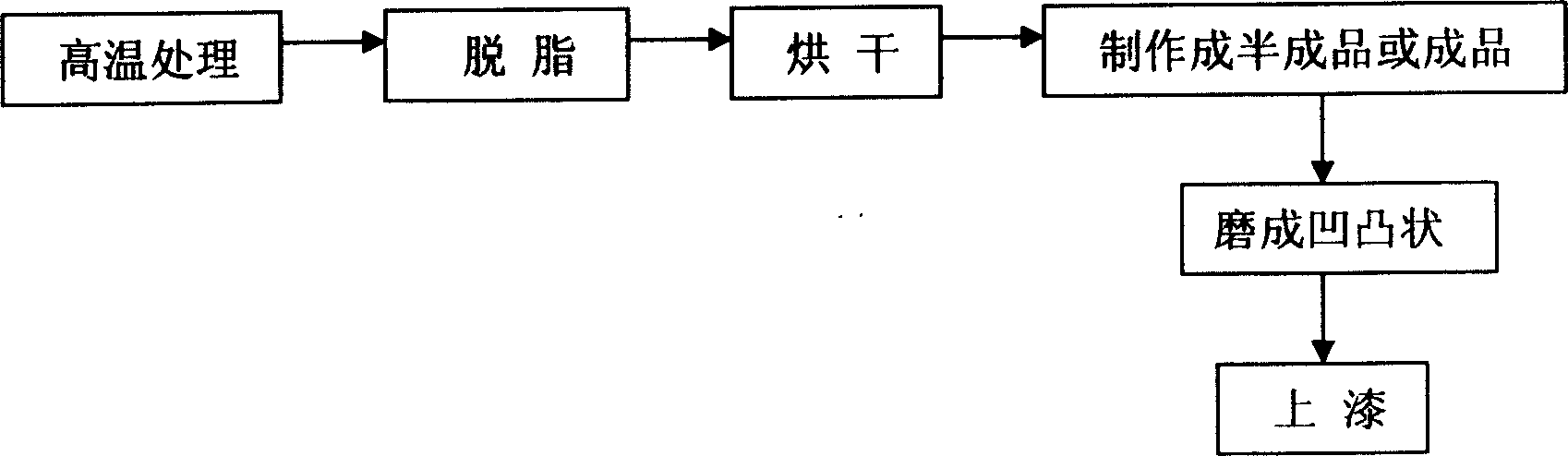

Wood semi-product or finished product working process

A processing technology and semi-finished product technology, applied in the direction of wood processing utensils, manufacturing tools, etc., can solve problems such as single color, and achieve the effect of simple and convenient processing technology, easy operation, and rich color changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] see figure 1 , this embodiment adopts Douglas pine as raw material, first carries out high temperature, degreasing and drying treatment to the wood, then makes the wood into semi-finished products, such as various parts of the wardrobe, and then uses the cup-shaped steel wire at the head of the angle grinder Brush the surface of the wood back and forth to polish it along the direction of the wood grain. When you touch it with your hands, you can feel obvious bumps. Because the wooden part of Douglas fir is hard and the wooden part is soft, under the high-speed grinding of the wire brush, the wooden part is removed by grinding, showing a concave shape, while the wooden part is still retained, showing a convex shape, so The entire surface of the wood molded product is concave-convex. Finally, the various parts of the wardrobe whose surface has been processed into a concave-convex shape are installed into a finished wardrobe, and the varnish can be applied.

[0015] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com