Integrated production process of fixedly-assembled furniture

A production process and furniture technology, applied in the field of home decoration, can solve the problems of labor and material waste, long construction period, difficult to buy furniture, etc., and achieve the effect of clear and natural wood grain and strong wood feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

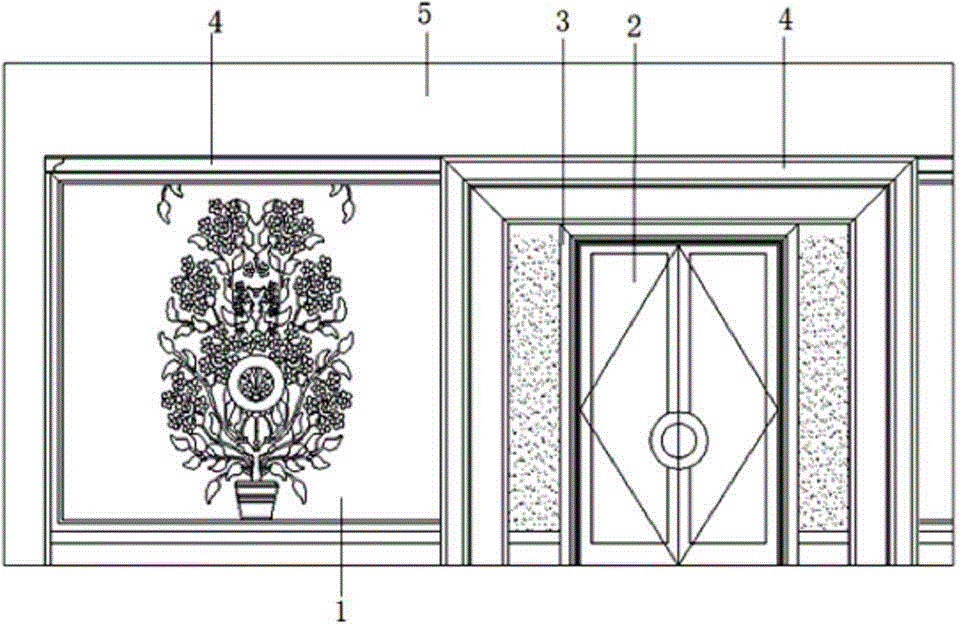

[0040] The data obtained from on-site measurement, according to the data combined with the design requirements, the drawings of wall veneer 1, door 2, door cover 3, wire frame 4, furniture and other components are designed, and the factory produces according to the design drawings. The factory sends the completed components to On-site installation.

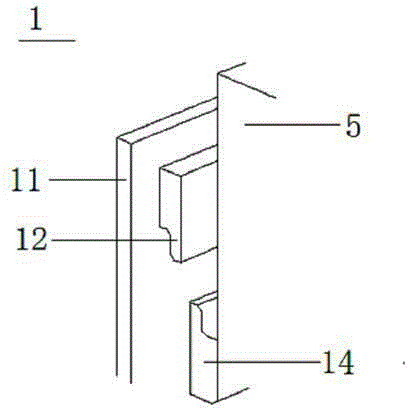

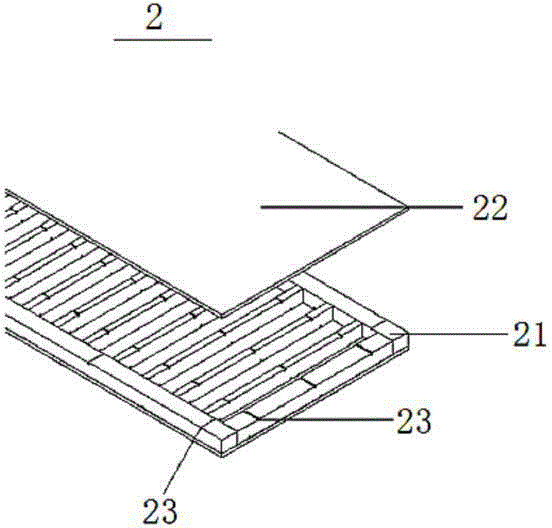

[0041] The wall 5 is provided with a built-in part 14, and the wooden veneer pendant 12 on the wooden veneer 11 is hung on the pre-embedded part 14, and the wall veneer 1 is connected with the wall 5, because the wooden veneer pendant 12 If there is, there is a gap between the wood veneer 11 and the wall 5 to prevent the wood veneer from being damp. The door pocket includes a door pocket cover line 31 and a door pocket doubler plate 32, and the door pocket cover line 31 is fixed on the wall body 5 On both sides of the door opening, there are clamping blocks 34 on the door cover doubler board 32, and the clamping block 34 is insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com