Straw concrete light steel keel self-insulation wallboard and construction method thereof

A light steel keel and concrete technology, which is applied in the processing of building materials, construction, building components, etc., can solve the problems of wall board cold bridge, wall board hollowing feeling, insufficient hanging force of wall board, resource consumption, etc., and achieve good results Thermal insulation performance, shortening the construction period, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

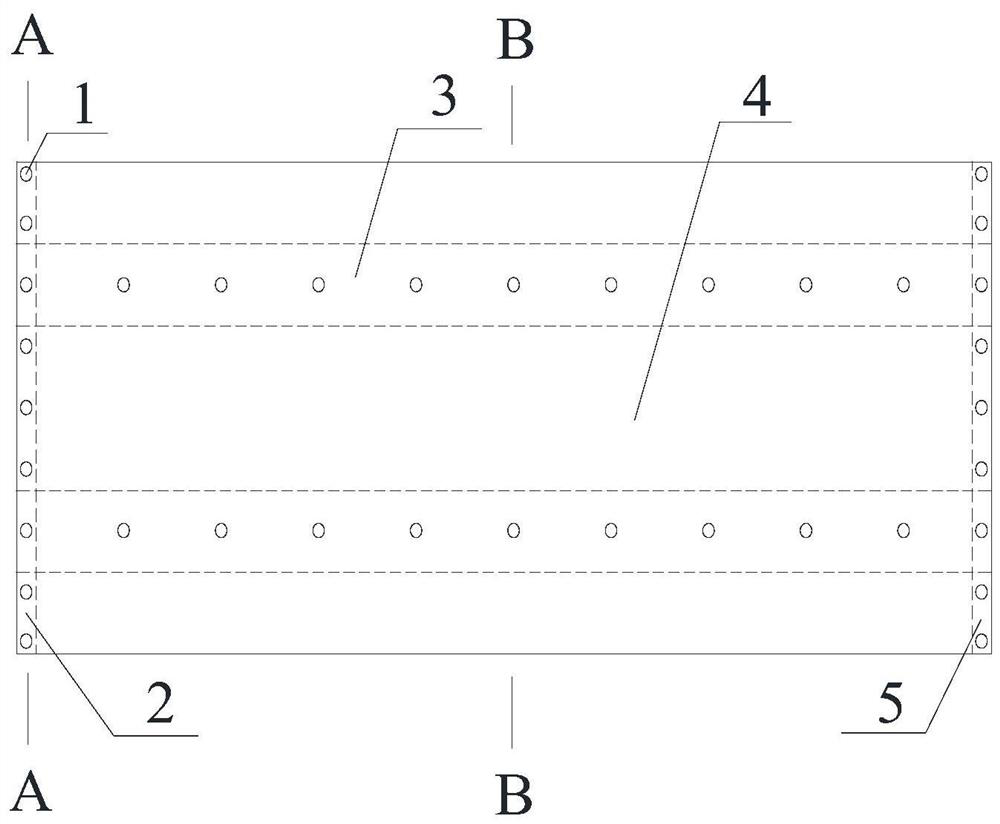

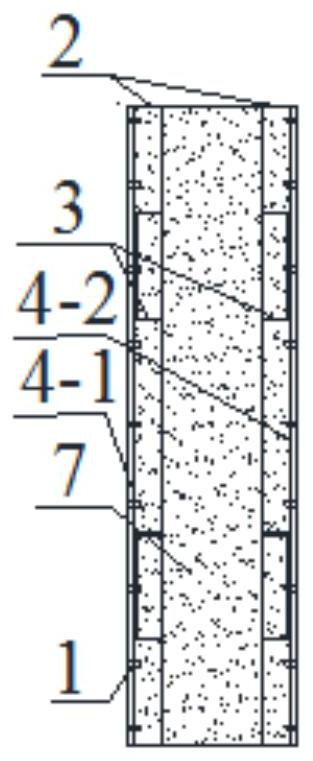

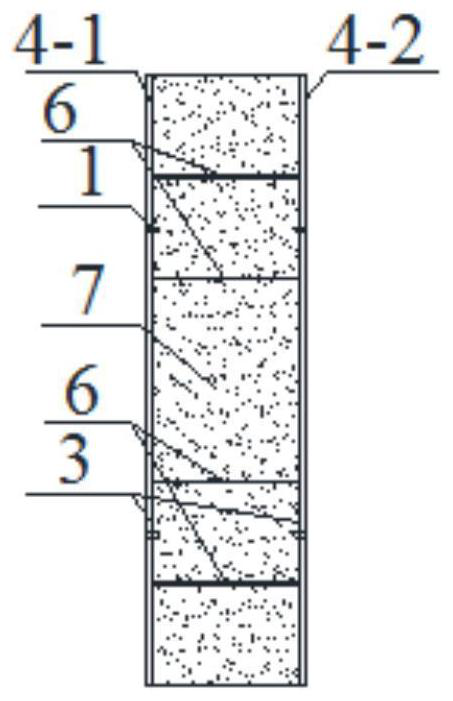

[0029] Such as Figure 1-Figure 6 As shown, a straw concrete light steel keel self-insulation wallboard includes a sky keel 2, an opposite C-shaped cold-formed thin-walled steel keel 3, an OSB board 4, a ground keel 5 and straw concrete 7, and the OSB board 4 is set Two pieces, respectively the lower OSB board 4-1 and the upper OSB board 4-2, two sets of opposed C-shaped cold-formed thin-walled steel keels 3 are provided, and the two groups of opposed C-shaped cold-formed thin-walled steel keels 3 are arranged in parallel , and both ends are respectively fixedly connected with the sky keel 2 and the ground keel 5 to form a keel frame, and the upper OSB board 4-1 and the lower OSB board ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com