Variable angle coupling mechanism

A technology of connecting mechanism and changing angle, applied in the direction of building components, building structures, walls, etc., can solve problems such as construction design is difficult to achieve, and achieve the effect of eliminating mutual restraint and welding stress, small error, and wide practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

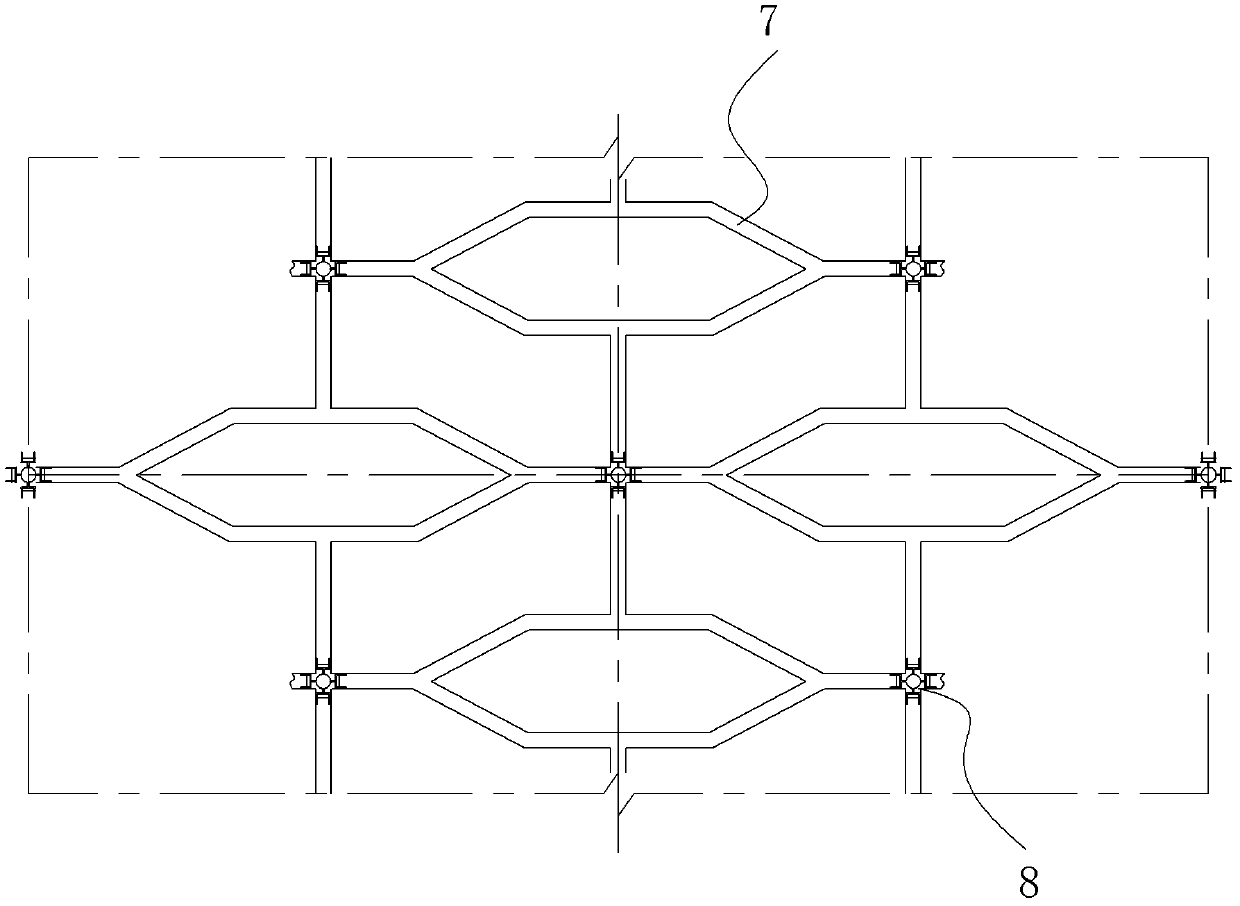

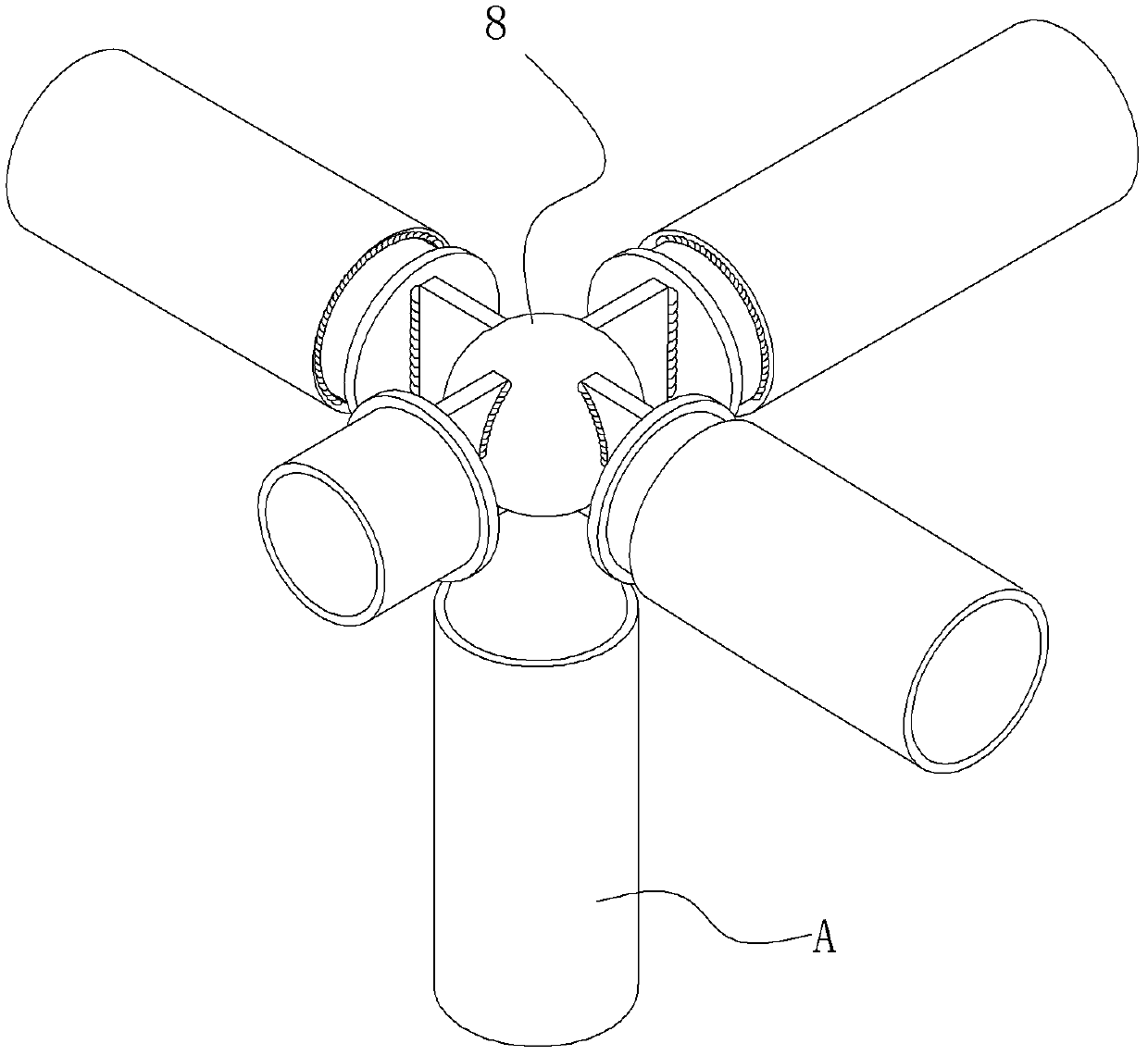

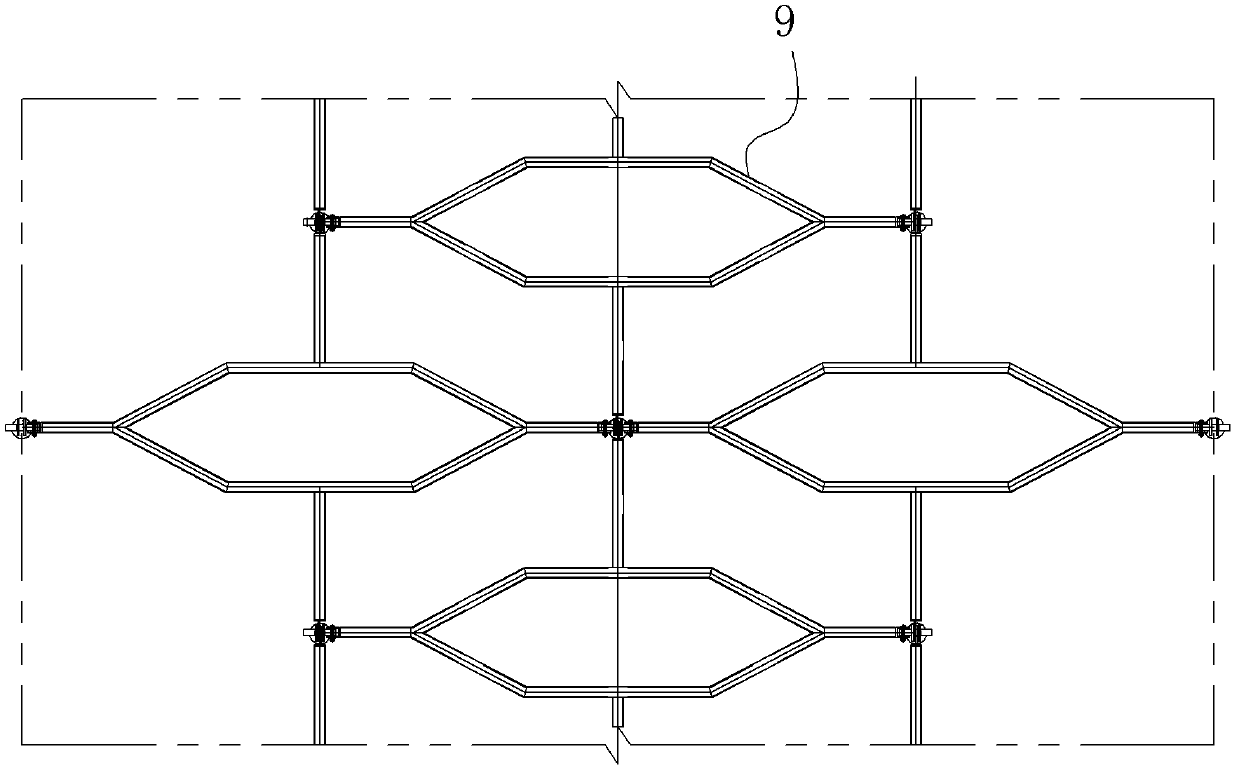

[0050] Such as Figure 3 to Figure 11As shown, a variable-angle coupling mechanism of the present invention includes a base 1 fixedly coupled to the main body structure (i.e., the support rod A), and a first coupling 21, a second coupling 22, and a third coupling connected to the base 1 23. The fourth coupling piece 24. The base 1 includes a bottom plate 11, two support plates 12A, 12B arranged above the bottom plate 11, and a central shaft 3 connected with the two support plates 12A, 12B. The first coupling piece 21, The second coupling part 22 is hingedly connected with the central shaft 3; the inner ends of the first coupling part 21 and the second coupling part 22 are respectively provided with a first hinged hole 210 and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com