A method for installing a corridor slab in a steel structure

An installation method and technology for walkway slabs, which are applied in building construction, construction material processing, construction and other directions, can solve the problems of inconvenient installation of walkway slabs, cost a lot of labor and welding materials, etc., so as to save welding materials and labor, improve The effect of on-site installation speed and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

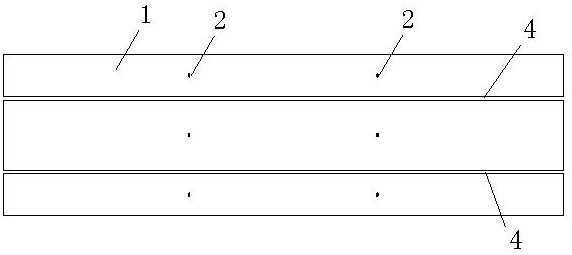

[0027] see now Figure 1-Figure 3 , the installation method of the steel structure corridor corridor plate of the present invention, comprises the following steps:

[0028] a. The steel structure manufacturing plant completes the processing of the components according to the steel structure drawings. The steel walkway plate can be processed into one section or two ends (8-12 meters long) according to the length of the corridor and the transportation requirements of the components, so as to reduce the on-site assembly workload;

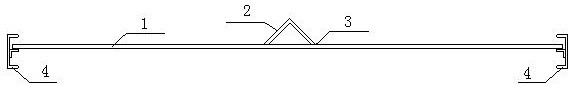

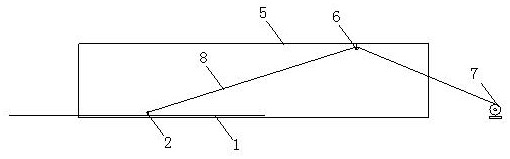

[0029] b. After the corridor frame 5 is assembled, start to install the walkway slab 1. First, take the L50 angle steel and cut it into small sections, each 30mm long. And prepare a pulley and a small winch;

[0030] c. Weld the cut small angle steel on the aisle slab to form a lifting ring, weld two angle steel lifting rings 2 on each aisle slab, and weld them to 1 / 3 positions on both sides of the aisle slab with welding seams 3;

[0031] d. Use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com