Ultraviolet light solidified wear resistant lacquer in use for coating layer on surface of dense board plastes

A technology of surface coating and ultraviolet light, which is applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of poor wear resistance, and achieve the effect of excellent wear resistance, clear wood grain and soft matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

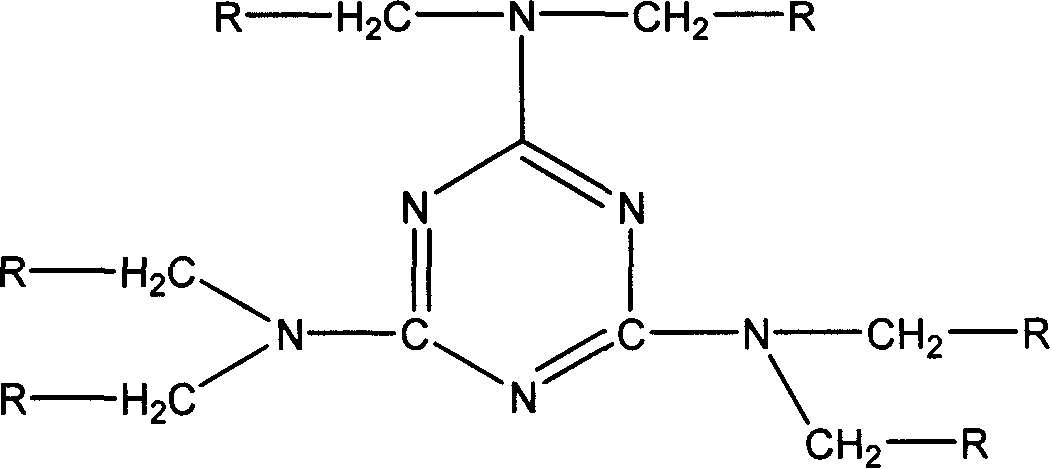

[0037] Hexafunctional acrylate modified amino resin 30%

[0038] Hexafunctional Urethane Acrylate 10%

[0039] Bisphenol A epoxy acrylate 10%

[0040] Trimethylolpropane Triacrylate 30%

[0041] 2-Methyl-2-hydroxyester-1-oxyphenylpropane (Darocure 1173 Ciba product) 5%

[0042] Matting Powder (OK 500 Degussa, Germany) 8%

[0043] Al 2 o 3 Powder (KD203 Hangzhou Xinglong) 7%

[0044] Mix the above components in a reaction kettle, heat to a temperature of 50-60°C, stir evenly for 0.5-3 hours, and disperse and emulsify for 0.5-3 hours. After cooling, the UV-curable wear-resistant coating specially used for the density plate of the heat-pressed paper film of the present invention is obtained. The paint was coated on the tinplate plate and the density plate with heat-pressed paper film with a wire bar, and its performance was measured after UV curing. The results are shown in Table 1.

Embodiment 2

[0046] Trifunctional acrylate modified amino resin 35%

[0047] Hexafunctional Urethane Acrylate 10%

[0048] Bisphenol A epoxy acrylate 15%

[0049] Trimethylolpropane Triacrylate 30%

[0050] 2-Methyl-2-hydroxyester-1-oxyphenylpropane (Darocure 1173 Ciba product) 3%

[0051] Matting powder (OK 500 Germany Degussa) 2%

[0052] Al 2 o 3 (KD 203 Hangzhou Xinglong) 5%

[0053] Prepared according to the method of Example 1, the UV-curable wear-resistant coating dedicated to the density plate of the present invention was obtained.

Embodiment 3

[0055]Hexafunctional acrylate modified amino resin 30%

[0056] Hexafunctional Urethane Acrylate 10%

[0057] Bisphenol A Epoxy Methacrylate 5%

[0058] Pentaerythritol Triacrylate 20%

[0059] Propoxylated Trimethylolpropane Trimethacrylate 10%

[0060] Ethoxylated Trimethylolpropane Triacrylate 5%

[0061] 2-Methyl-2-hydroxyester-1-oxyphenylpropane (Darocure 1173 Ciba product) 5%

[0062] Matting Powder (OK 500 Degussa, Germany) 8%

[0063] al 2 o 3 Powder (KD 203 Hangzhou Xinglong) 7%

[0064] Prepared according to the method of Example 1, the UV-curable wear-resistant coating dedicated to the density plate of the present invention can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com