Wind power blade connecting device

A technology of connecting device and wind power blade, which is applied to wind power generation, wind turbines that are consistent with the wind direction, wind turbines, etc., can solve the problem of reducing the fatigue life of bolts, increasing the connection load factor and bearing fatigue load, and increasing the dead weight of segmented blades. and other problems, to achieve the effect of simplifying the machining process, solving the increase in self-weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the drawings and specific embodiments.

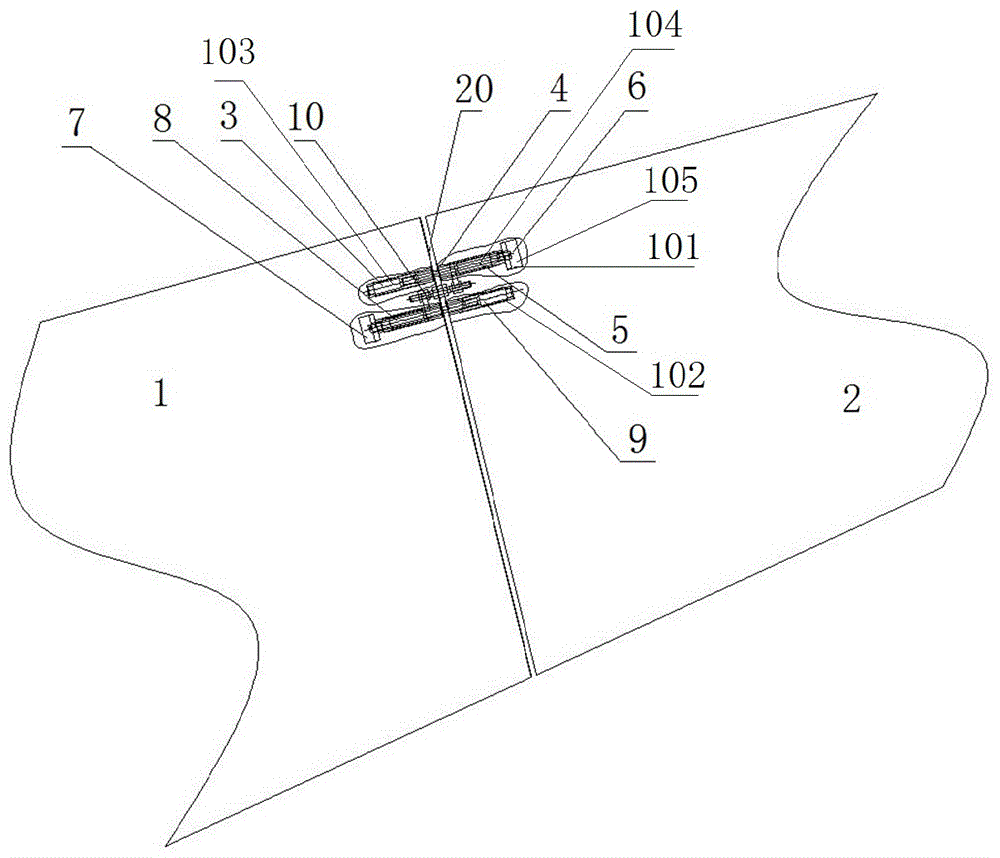

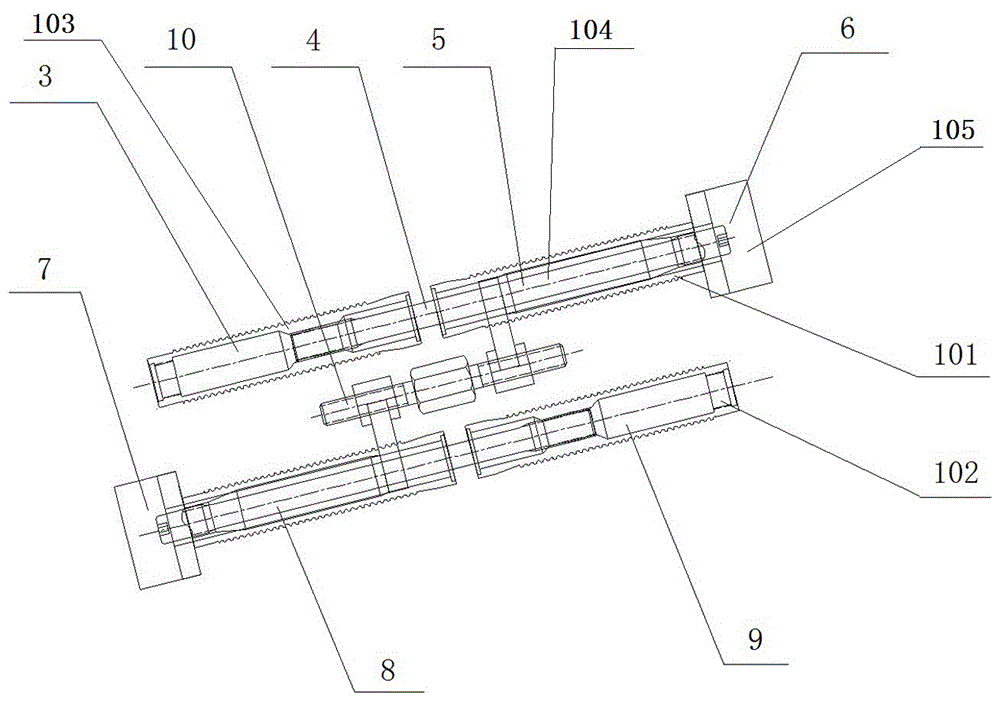

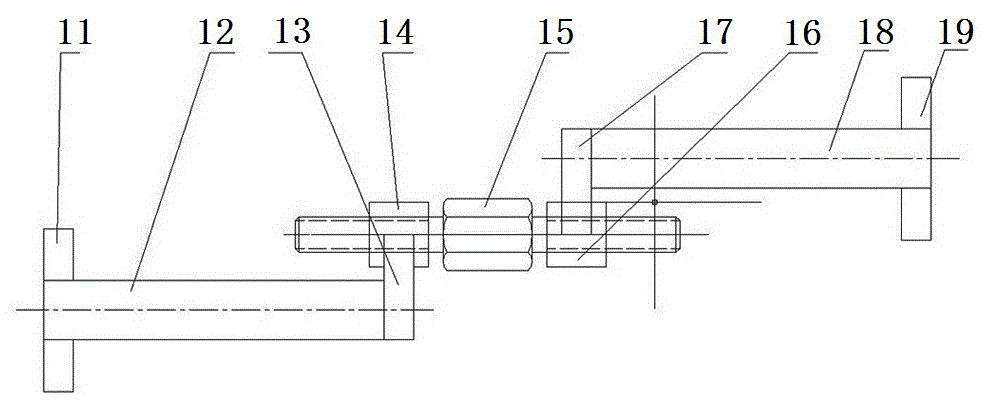

[0021] Such as figure 1 with 2 A wind turbine blade connecting device is shown. There are at least two sets of connecting devices. The adjacent two sets are arranged in forward and reverse directions and are connected by a tensioner 10. The bolt assembly 4 of the connecting device connects the segmented blade root section 1 and the segmented blade. The blade tip section 2 is connected, one end of the bolt assembly 4 is connected to the bolt sleeve 103, the other end of the bolt assembly 4 is connected to the light sleeve 104, the end of the light sleeve 104 is provided with a wrench space 105, the structure of the light sleeve 104 and the bolt sleeve 103 Same, but without thread inside and open at both ends. One end of the bolt assembly 4 connected to the light sleeve 104 passes through the light sleeve 104 and extends into the wrench space 105; the segmented bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com