Manufacturing process of thrust washer

A manufacturing process and thrust piece technology, applied in mechanical equipment, connecting components, etc., can solve the problems of unitary production and manufacturing of components, cannot guarantee product quality and required product functions, etc., and meet strict requirements, simple machining process, and technical standards. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

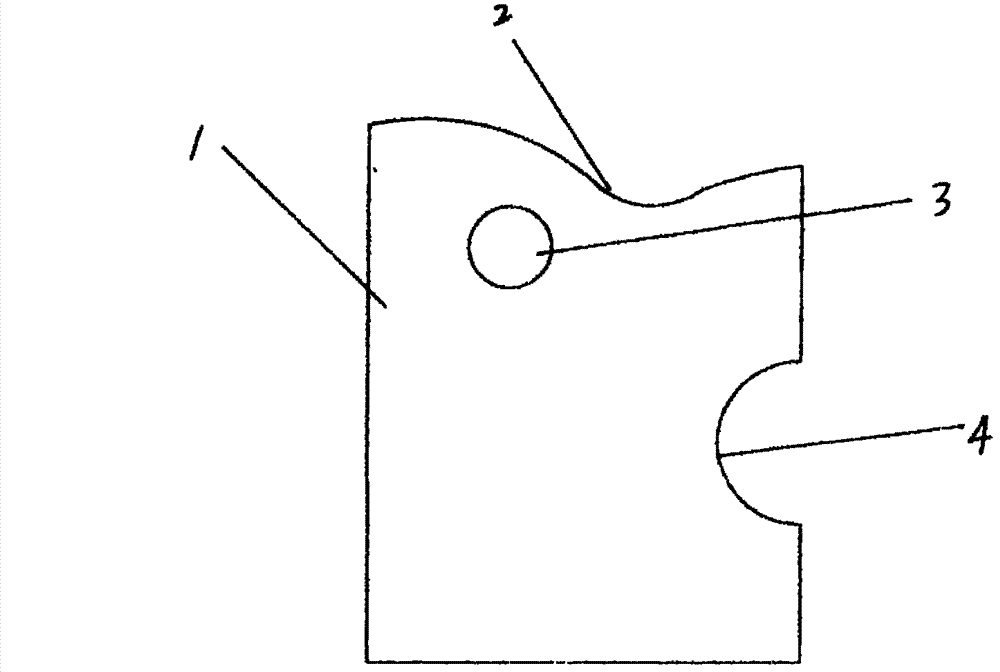

[0009] The invention will be further described below in conjunction with the accompanying drawings.

[0010] In the view, take a thrust plate as an example: Use a stainless steel plate with a thickness of 0.5 mm to stamp out the thrust plate on the cold press die of the punching machine 1 Shape-fine undulating edge 2, semicircular stop of the shaft sleeve 4-drilling Shaft hole 3-removal of processing sharp corners, burrs-surface polishing-surface degreasing, rust removal-surface electropolishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com