Wind power blade and manufacturing technology thereof

A wind power blade and manufacturing process technology, which is applied in the field of wind power blades and their manufacturing processes, can solve the problems of increasing the processing process and increasing the weight of the blade in the production of the blade-shaped skeleton, so as to simplify the machining process, improve the fatigue strength, and ensure smooth transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] The following uniaxial fabrics, biaxial fabrics and triaxial fabrics are all commercially available in the market.

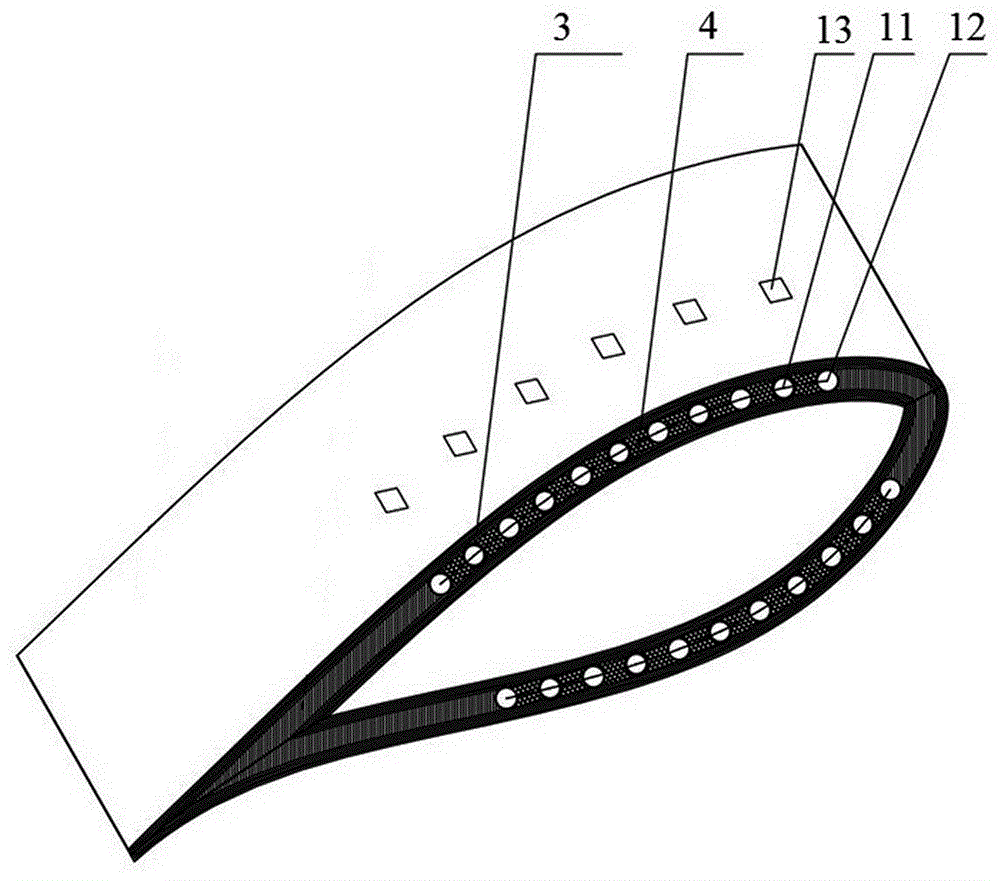

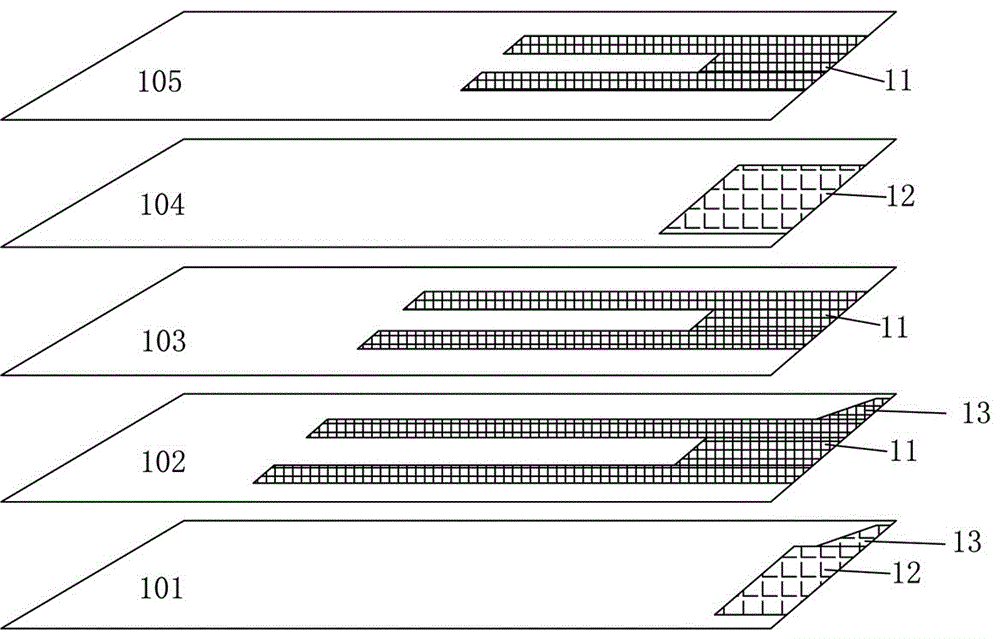

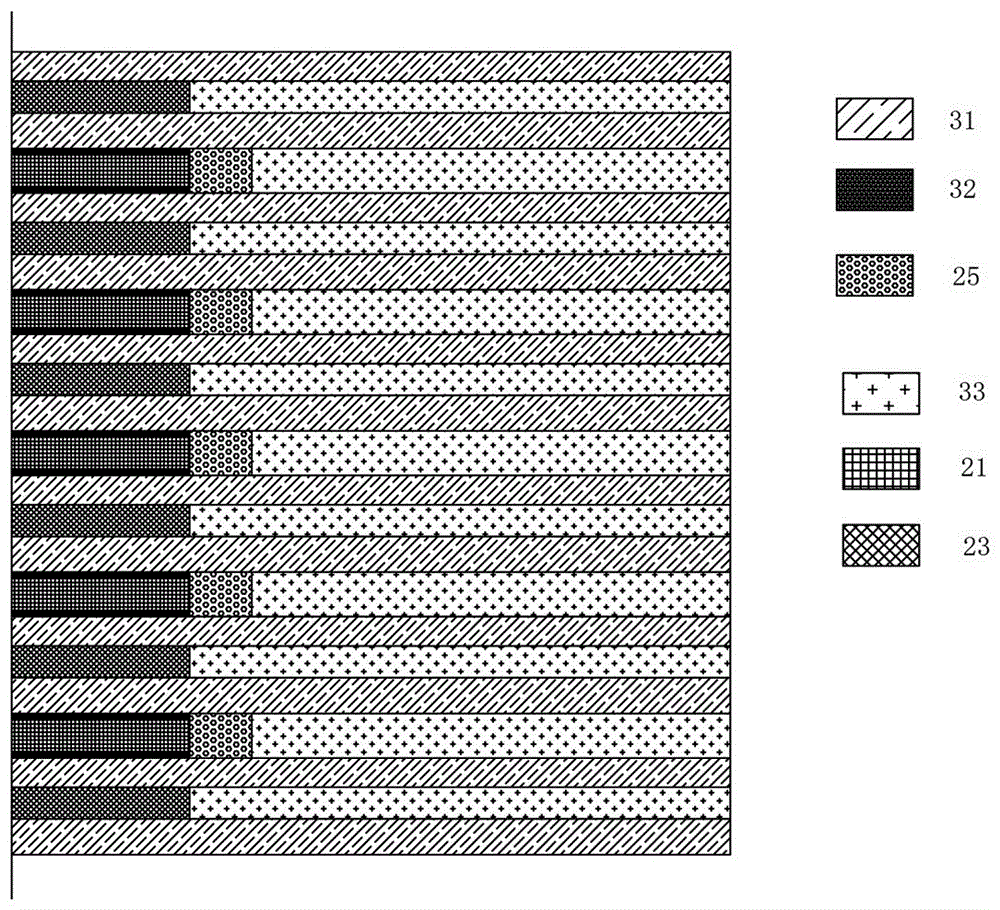

[0039] A wind turbine blade, such as figure 1 As shown, it includes at least two blade sections, the blade section includes a blade root section 201 and a blade tip section 202, a connecting device is provided between each blade section to connect the blade as a whole, and a reinforcement layer 205 under the embedded part is laid at the section connection. , the reinforcement layer is composed of at least 3 layers of uniaxial fabric 11 and at least 2 layers of triaxial fabric 12 between layers, uniaxial fabric 11 is chord-wise butted, triaxial fabric 12 is chord-wise lapped, and laying at segmental joints The trailing edge reinforcement cloth 15, the tail edge reinforcement cloth 15 is approximately triangular; the embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com