Method for forming laminated composite material by laser impact and application of method

A laser shock, composite material technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of complex forming process, high preparation cost, low processing efficiency, etc., to achieve simple processing flow, laminated bonding strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

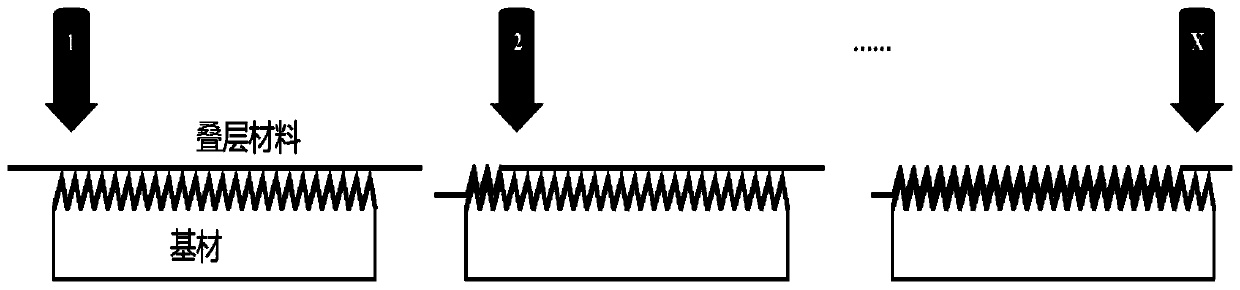

[0031] One of the characteristics of the preparation of laminated composite materials proposed by the present invention is that the pulsed laser can cause plasma explosion on the surface of the material, thereby forming an impact pressure of GPa level. During laser shock processing, thicker substrates undergo significant surface plastic deformation, while thinner laminates undergo significant global plastic deformation. The present invention proposes to use a metal material with higher hardness or higher thickness as the base material, and after preparing a rough surface with higher surface roughness on the surface of the base material, the laminated material with low hardness or low thickness covered on the rough surface of the base material Laser shock treatment is carried out, and the final base material and laminated materials form a state of close contact or welding under the impact pressure.

[0032] The second characteristic of the preparation of the laminated composite...

Embodiment 1

[0036] A preparation method of laser shock forming laminated composite material, comprising the steps of:

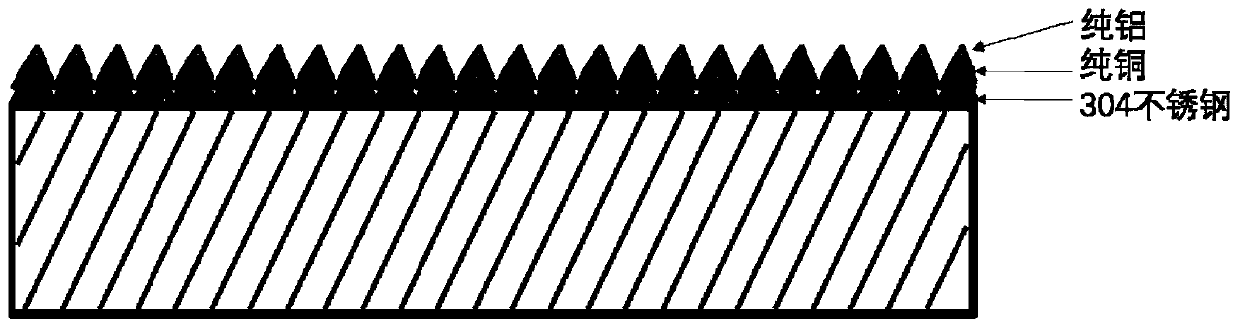

[0037] (1) 304 stainless steel with a thickness of 5mm is used as the base material; the surface of the base material is ground with 150 mesh sandpaper to obtain a surface roughness of about Ra1; then the base material after the grinding process is ultrasonically cleaned, and the cleaning solution is Ethanol, wash at room temperature for 5 minutes to remove impurities on the surface of the substrate; after completion, a clean substrate is obtained for future use.

[0038] (2) Select pure copper and pure aluminum foils as laminated materials. The thickness of the two foils is about 0.1mm, and they have a smooth surface. Before lamination, the two foils are ultrasonically cleaned. The cleaning solution is ethanol, room temperature Clean for 30 seconds under the same conditions to remove impurities on the surface of the substrate, and set aside; since the substrate stainles...

Embodiment 2

[0042] A preparation method of laser shock forming laminated composite material, comprising the steps of:

[0043] (1) Take the TC4 titanium alloy sheet with a thickness of 0.5mm as the substrate; the surface of the substrate is ground with 150 mesh sandpaper to obtain a surface roughness of about Ra0.8; then the ground substrate is ground Ultrasonic cleaning, the cleaning solution is ethanol, at room temperature for 1 minute, and set aside.

[0044] (2) Select duralumin 2A11 sheet and pure aluminum sheet as laminated materials. The thickness of duralumin 2A11 sheet is about 0.2mm, and the thickness of pure aluminum sheet is about 0.15mm. The two sheets have smooth surfaces. Ultrasonic cleaning is performed on the two foils before combining, the cleaning solution is ethanol, and it is cleaned at room temperature for 20 seconds, and then set aside.

[0045] (3) Reference figure 1 , Place a smooth-surfaced duralumin 2A11 sheet (ie laminate) on a rough-surfaced TC4 titanium all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com