Contact type connected electronic equipment

A kind of electronic equipment, contact technology, applied in the direction of connection, fixed connection, branch equipment, etc., can solve the problems of circuit connection instability, poor conductivity, high processing precision, etc., to achieve good contact circuit conduction performance, circuit conduction Good performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

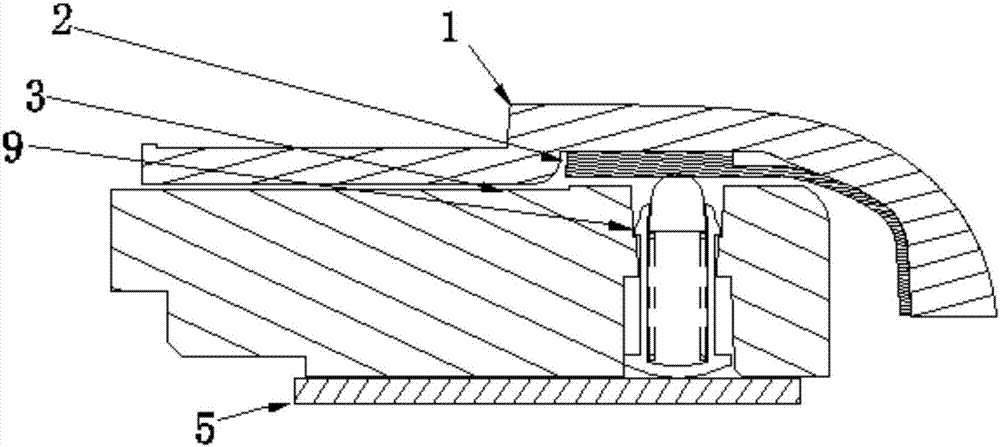

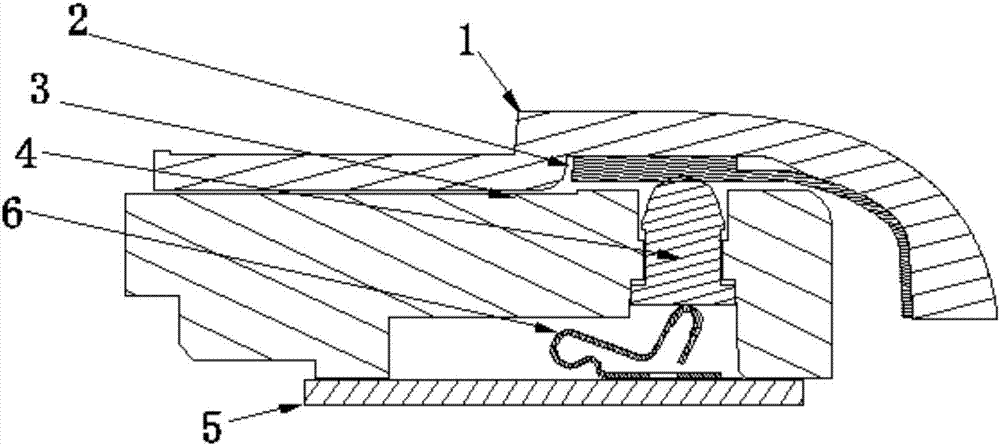

[0035] see image 3 , Figure 4 , the present invention discloses a contact-connected electronic device, said electronic device comprising: flexible circuit board FPC 2 (also can be rigid circuit board), FPC support 1, spring pin (POGO PIN) 4, spring pin (POGO PIN) 4, spring pin (POGO PIN) PIN) bracket 3, patch shrapnel 6, PCB board 5.

[0036] The FPC 2 is arranged on one side of the FPC support 1 , and the pin support 3 is provided with a through hole corresponding to the size of the pin 4 . The pin support 3 is provided with a groove, the groove communicates with the through hole, and the patch shrapnel 6 is arranged in the groove.

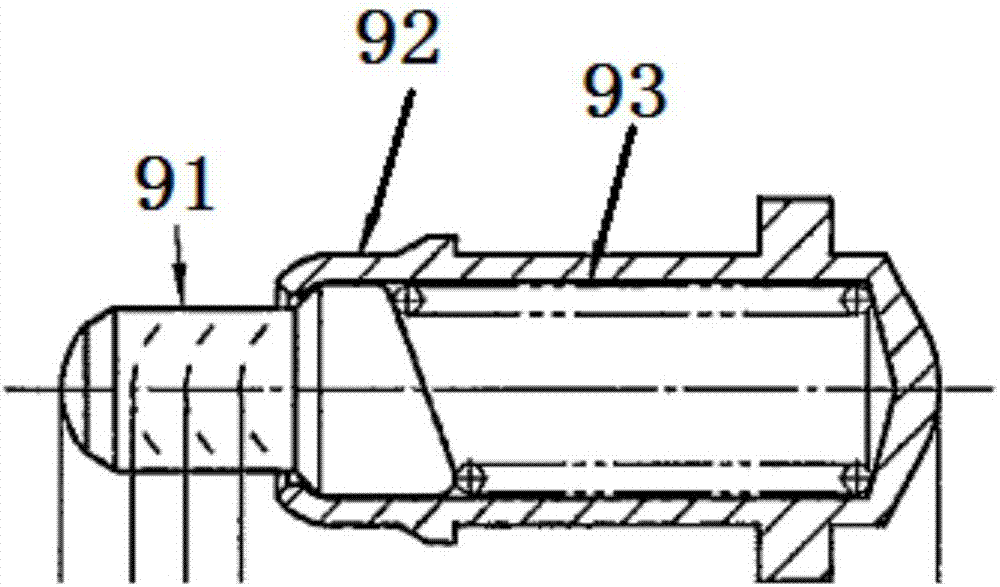

[0037] see Figure 5 , Image 6 , the elastic pin 4 is a solid structure; the length and diameter of the elastic pin can be adjusted accordingly according to the requirements of the structure. see Figure 7 , Figure 8 , the patch elastic piece 6 includes an elastic component and a seat body, and the elastic component is connected with t...

Embodiment 2

[0040] An electronic device connected by contact, the electronic device comprising: a circuit board, a circuit board support, a spring pin, a spring pin support, an elastic mechanism, and a PCB board; the circuit board is arranged on one side of the circuit board support, and the spring pin The bracket is provided with a through hole; one end of the elastic pin is connected to the circuit board through the corresponding through hole, and the other end is connected to the first end of the elastic mechanism; the second end of the elastic mechanism is fixedly connected to the PCB board.

[0041] To sum up, the electronic device with contact connection proposed by the present invention achieves better conduction performance of the contact circuit by simplifying the POGOPIN processing and assembling process. The present invention adopts solid POGOPIN, which is simple in processing, post-processing, and low in cost; the combined structure of solid POGOPIN and patch shrapnel is conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com