Touch screen and manufacture method thereof

A manufacturing method and touch screen technology, applied in the field of touch screens, can solve the problems of low processing efficiency, slow aerosol printing speed, cumbersome yellow light lithography process, etc., and achieve the effect of improving processing efficiency and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

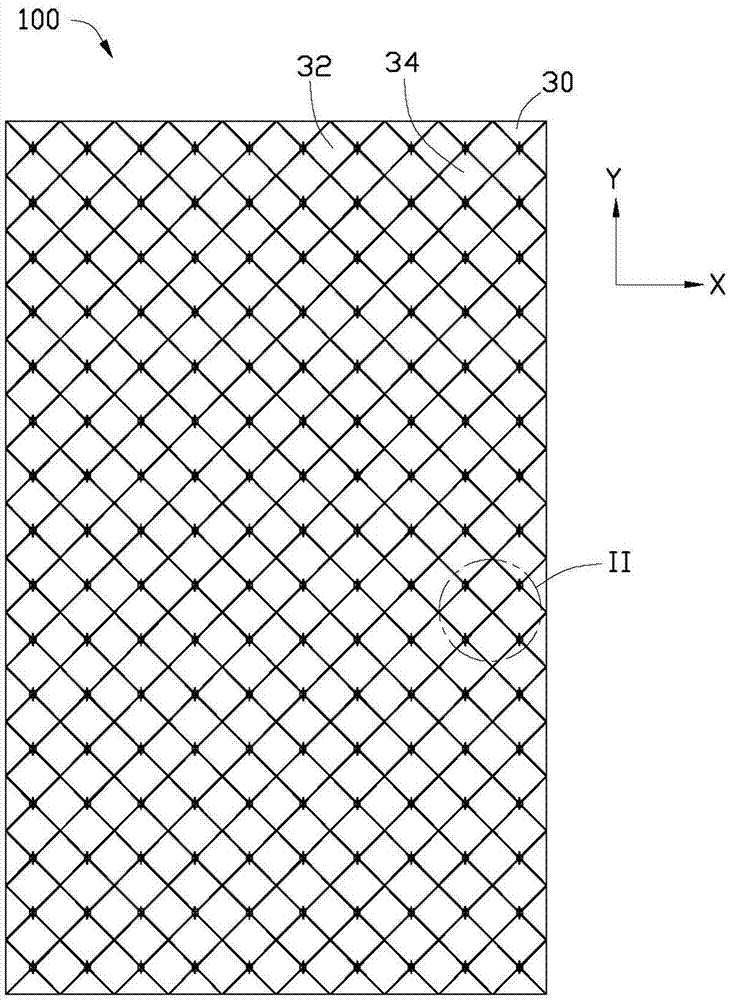

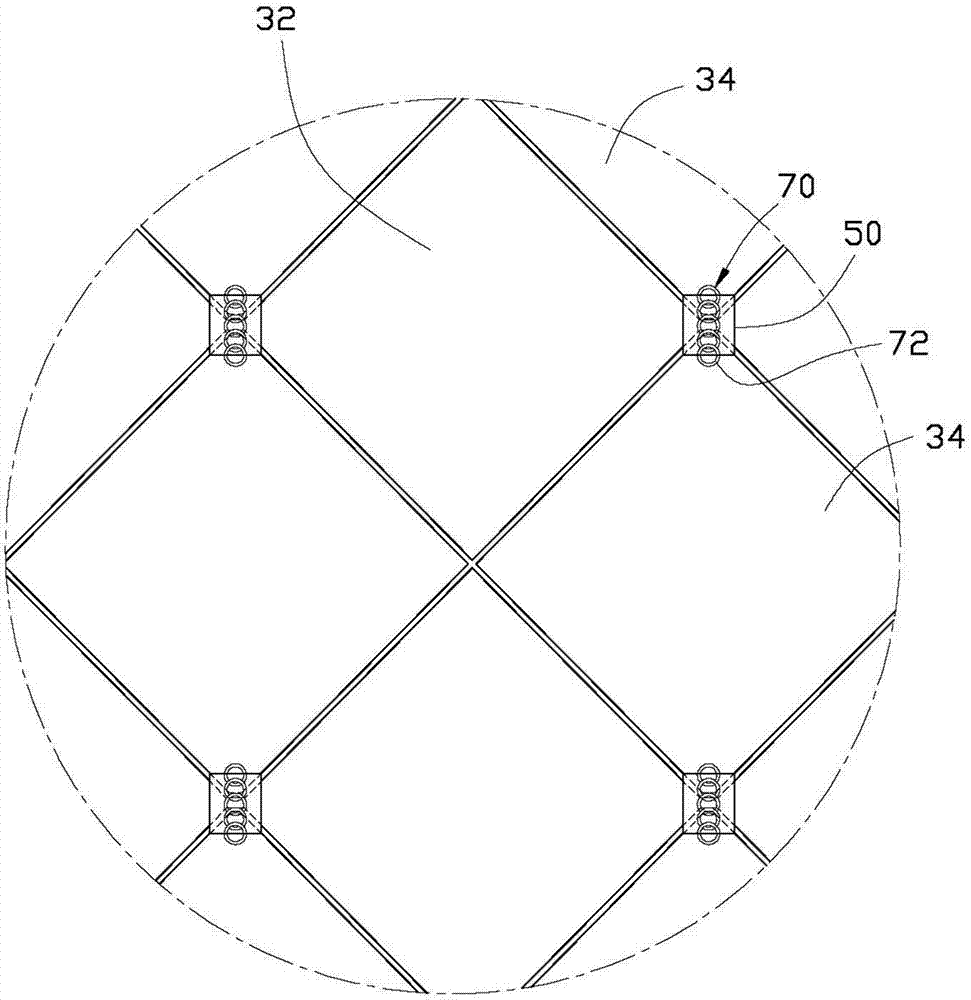

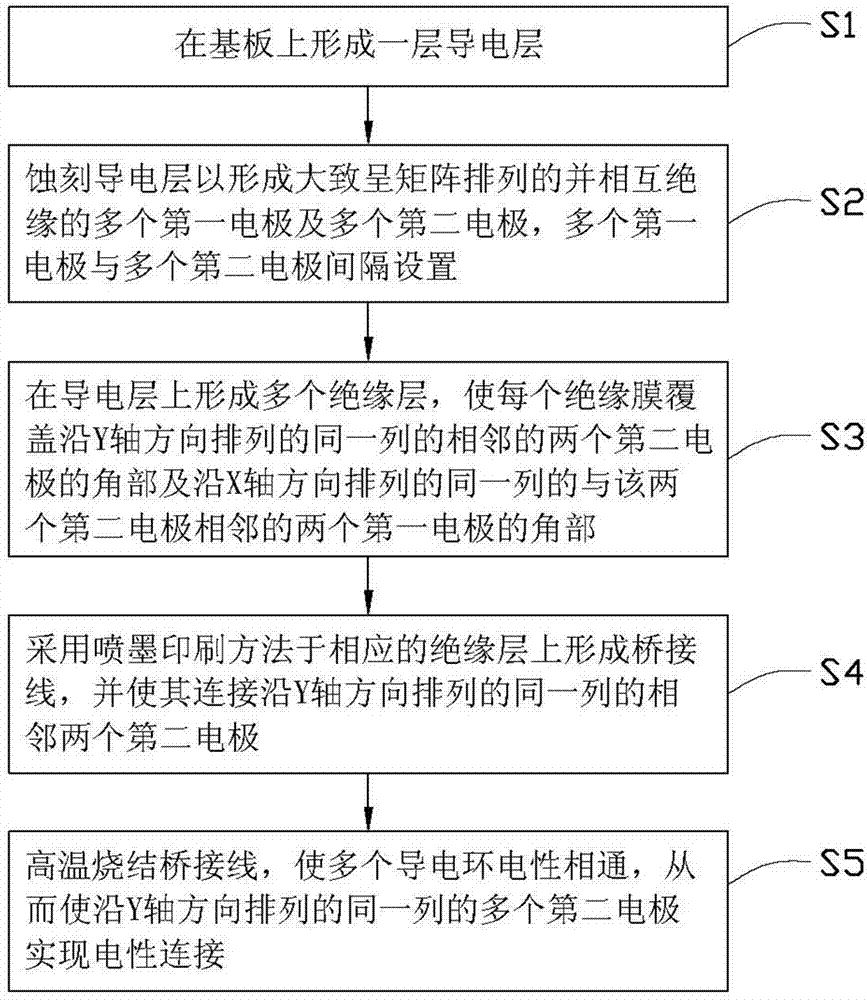

[0014] Please also refer to figure 1 and figure 2 The touch screen 100 according to the embodiment of the present invention includes a substrate 10 , a conductive layer 30 formed on the surface of the substrate 10 , a plurality of insulating layers 50 and a plurality of bridging lines 70 . In the embodiment of the present invention, the substrate 10 is made of a transparent insulating material, which may be made of transparent glass, polyethylene terephthalate (PET) and other materials.

[0015] The conductive layer 30 is formed with a plurality of first electrodes 32 and a plurality of second electrodes 34 arranged roughly in a matrix, the plurality of first electrodes 32 and the plurality of second electrodes 34 are insulated from each other, and the first electrodes 32 and the second electrodes 34 are arranged alternately with each other in columns. In the embodiment of the present invention, both the first electrode 32 and the second electrode 34 are approximately diamo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com