Processing method of chaenomeles sinensis koehne clear juice

A light-skinned papaya and processing method technology, applied in the field of food processing, can solve problems affecting the taste and quality of fruit juice, easily browning fruit juice components, adverse reactions, etc., to improve appearance and color quality, increase light transmittance and stabilize performance, and the effect of improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

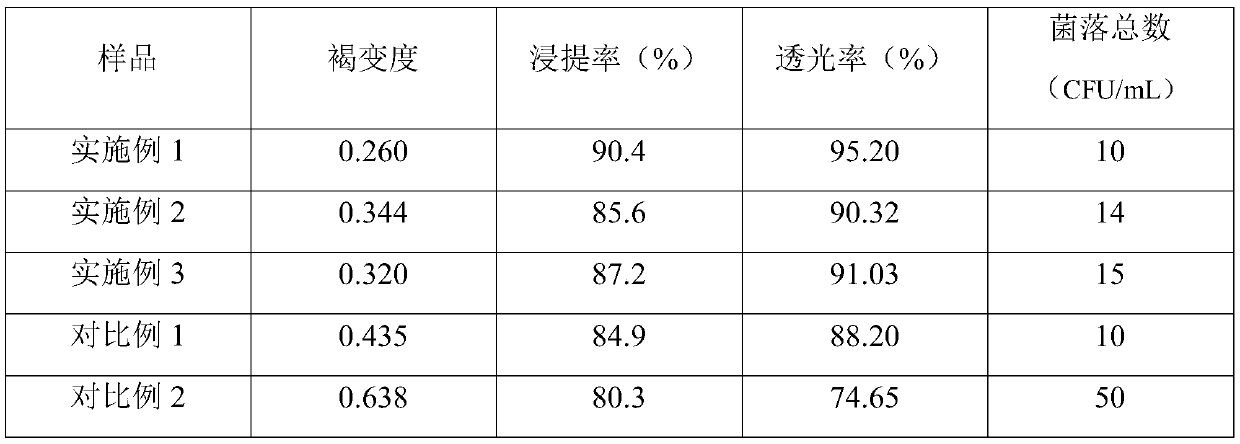

Embodiment 1

[0046] Embodiment 1: the preparation of clarified fruit juice of papaya with light skin

[0047] (1) Crushing papaya with light skin to a particle size of 3-5mm, adding a composite color-protecting agent during the crushing process, the composite color-protecting agent is composed of CaCl 2 , EDTA-2Na, sodium erythorbate and L-cysteine are composed in a weight ratio of 100:2:15:10, and the addition amount is 0.5% of the weight of papaya papaya.

[0048] (2) Mix the crushed papaya with deionized water at a weight ratio of 1:3 to obtain a mixed slurry, add cellulose compound enzyme and pectinase to the mixed slurry for enzymatic extraction, and the fiber The addition of the element compound enzyme is 0.076% of the weight of the mixed slurry, and the addition of pectinase is 0.052% of the weight of the mixed slurry; the enzymolysis temperature is 50°C, the enzymolysis time is 1.5h, and the enzymolysis is carried out at 90°C Inactivate the enzyme for 15 minutes, cool and filter...

Embodiment 2

[0051] Embodiment 2: the preparation of clarified fruit juice of papaya with light skin

[0052] (1) Crushing papaya with light skin to a particle size of 3-5mm, adding a composite color-protecting agent during the crushing process, the composite color-protecting agent is composed of CaCl 2 , EDTA-2Na, sodium erythorbate and L-cysteine are composed in a weight ratio of 100:2:15:10, and the addition amount is 0.4% of the weight of papaya papaya.

[0053] (2) Mix the crushed papaya with deionized water at a weight ratio of 1:2 to obtain a mixed slurry, add cellulose compound enzyme and pectinase to the mixed slurry for enzymatic extraction, and the fiber The addition of the compound enzyme is 0.06% of the weight of the mixed slurry, and the addition of pectinase is 0.08% of the weight of the mixed slurry; the enzymolysis temperature is 45°C, the enzymolysis time is 2h, and the enzymolysis is extinguished at 90°C. Enzyme for 15 minutes, cool and filter, collect the filtrate, a...

Embodiment 3

[0056] Embodiment 3: the preparation of clarified fruit juice of papaya with light skin

[0057] (1) Crushing papaya with light skin to a particle size of 3-5mm, adding a composite color-protecting agent during the crushing process, the composite color-protecting agent is composed of CaCl 2 , EDTA-2Na, sodium erythorbate and L-cysteine are composed in a weight ratio of 100:2:15:10, and the addition amount is 0.45% of the weight of papaya papaya.

[0058] (2) Mix the crushed papaya with deionized water at a weight ratio of 1:4 to obtain a mixed slurry, add cellulose compound enzyme and pectinase to the mixed slurry for enzymatic extraction, and the fiber The addition of the element compound enzyme is 0.1% of the weight of the mixed slurry, and the addition of pectinase is 0.04% of the weight of the mixed slurry; the enzymolysis temperature is 55°C, the enzymolysis time is 1.0h, and the enzymolysis is carried out under the condition of 90°C Inactivate the enzyme for 15 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com