Mask group suitable for multi-overlay multi-time sequence photoetching pattern and fabrication method of mask group

A photolithographic pattern and mask technology, which is applied to the photoengraving process of the pattern surface, the original for optical mechanical processing, optics, etc. Micro-machining flexibility and other issues, to achieve the effect of facilitating the processing process, saving the quantity and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

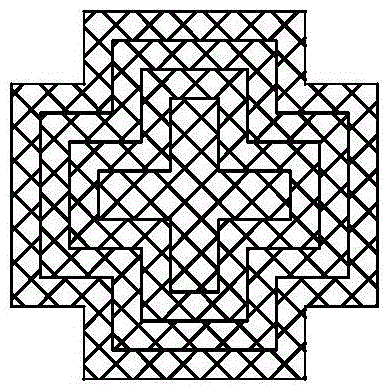

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

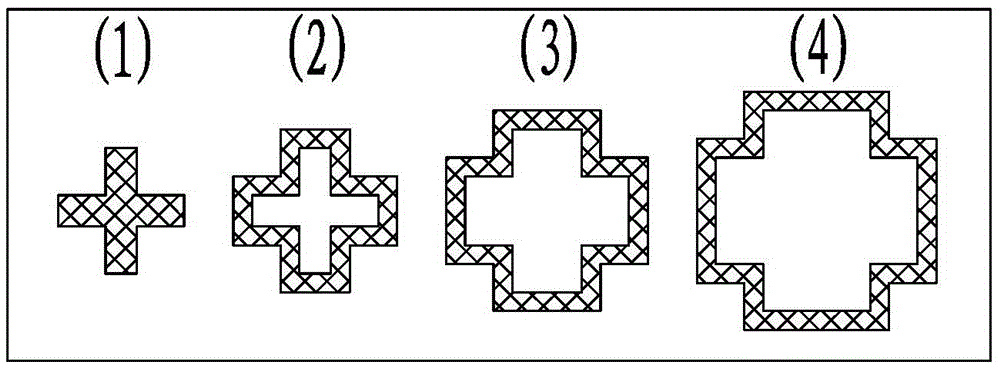

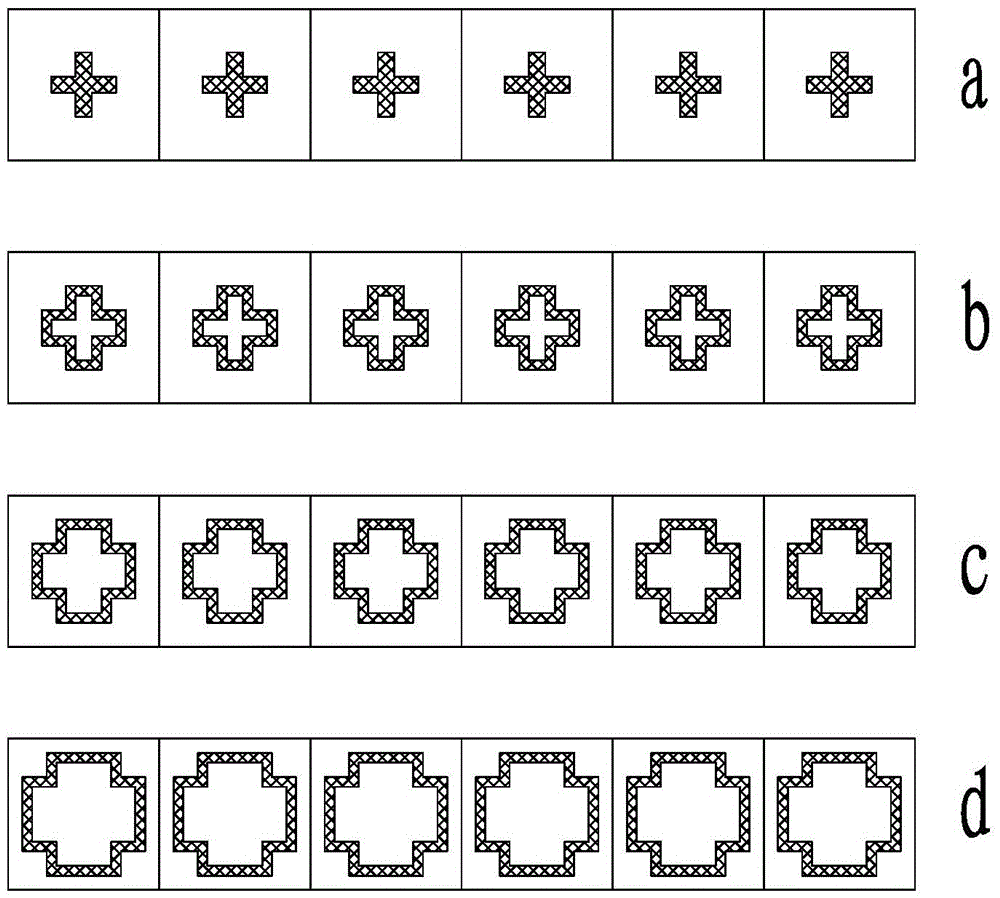

[0028] Embodiment 1 of the present invention provides a mask set suitable for multi-sequence lithography patterns for multiple overlays, including multiple masks, the number of masks is m+1, m is the number of overlays, in,

[0029] Each mask plate is evenly divided into a plurality of pattern areas, the total area of the pattern areas is equal to the surface area of the mask plate, and the number of pattern areas is at least m+1. In order to highlight the diversification of the mask processing sequence, each mask is evenly divided pattern area, and m is the number of overlays.

[0030] Each pattern area is provided with a light-shielding layer, and a light-transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com