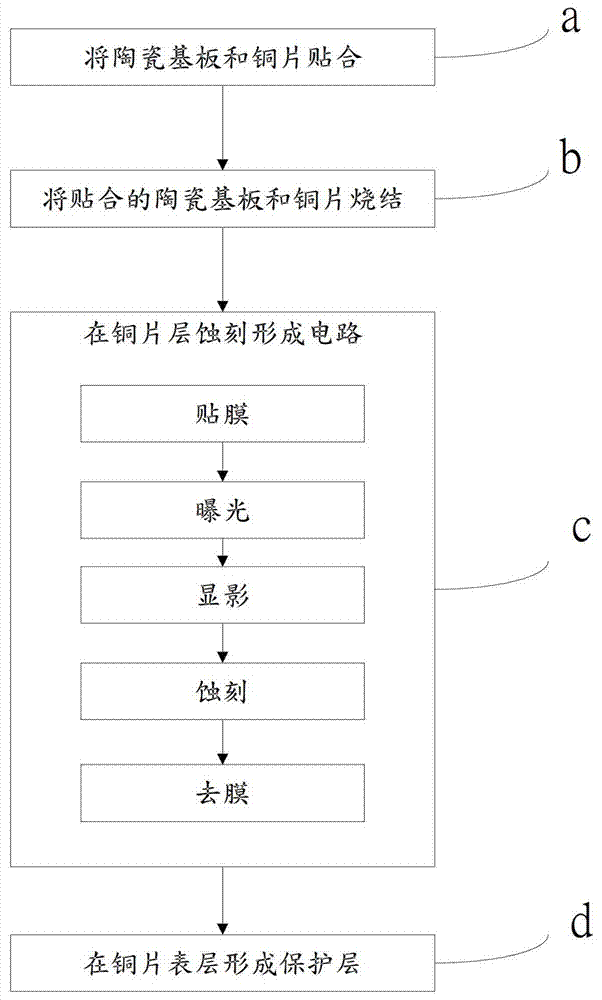

Copper-clad ceramic substrate manufacturing method

A technology of copper-clad ceramic substrate and manufacturing method, which is applied in printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problems of increasing environmental pressure, inconvenient recycling, complex process, etc., to reduce the pressure of wastewater treatment and facilitate recycling. , the effect of good isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

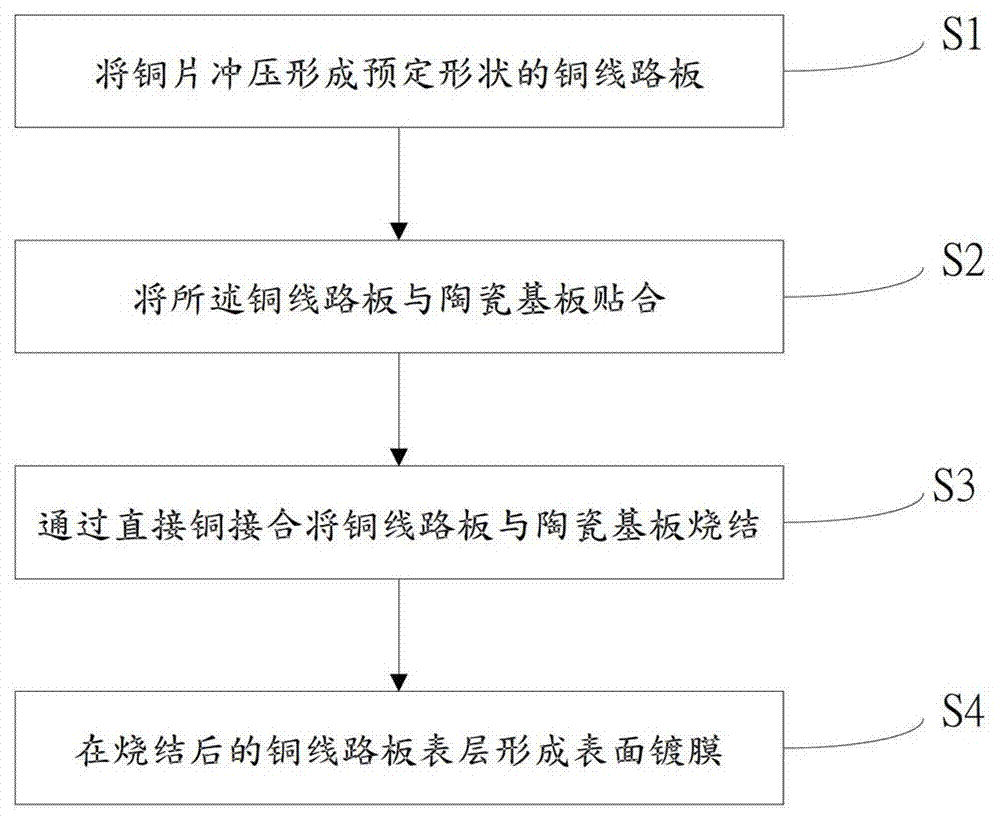

[0020] refer to image 3 As shown, the manufacturing method of the copper-clad ceramic substrate disclosed in the present invention comprises:

[0021] S1, stamping the copper sheet to form a copper circuit board 1 of a predetermined shape;

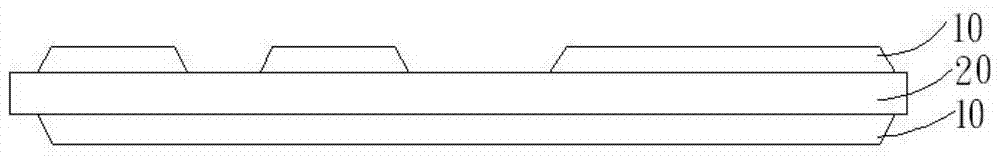

[0022] S2, laminating the copper circuit board 1 and the ceramic substrate 2;

[0023] S3 , sintering the copper circuit board 1 and the ceramic substrate 2 by direct bonding copper (Direct Bonding Copper, DBC). The copper circuit board 1 formed by stamping has neat side walls and is perpendicular to the ceramic 2 substrate, has good isolation performance, and has a simple process and low cost. In specific implementation, the copper circuit board 1 and the ceramic substrate 2 can be sintered by heating oxidation method, wherein the oxidation temperature is 950°C-1100°C, and the oxidation time is 20min-35min. During the heating oxidation process, the oxidation atmosphere can be preferably It is a weak oxygen atmosphere under the protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com