Acetylene production system with high utilization rate and production method

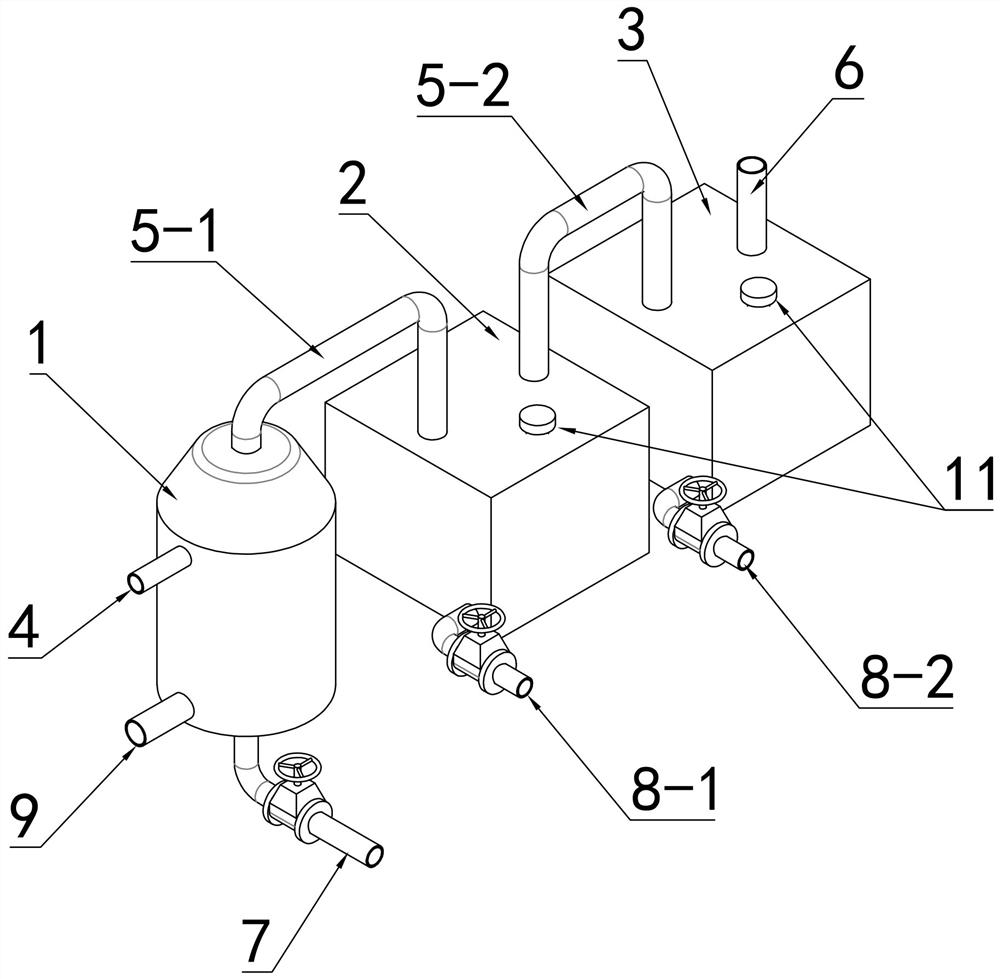

A technology of production system and production method, which is applied in the direction of acetylene generator, parts of acetylene gas generator, petroleum industry, etc., which can solve the problems of large volume, inability to fully contact and react with water, severe reaction that is difficult to control, and purification equipment occupying Large ground and other issues, to achieve the effect of preventing liquid splashing, increasing polarity, and saving site space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

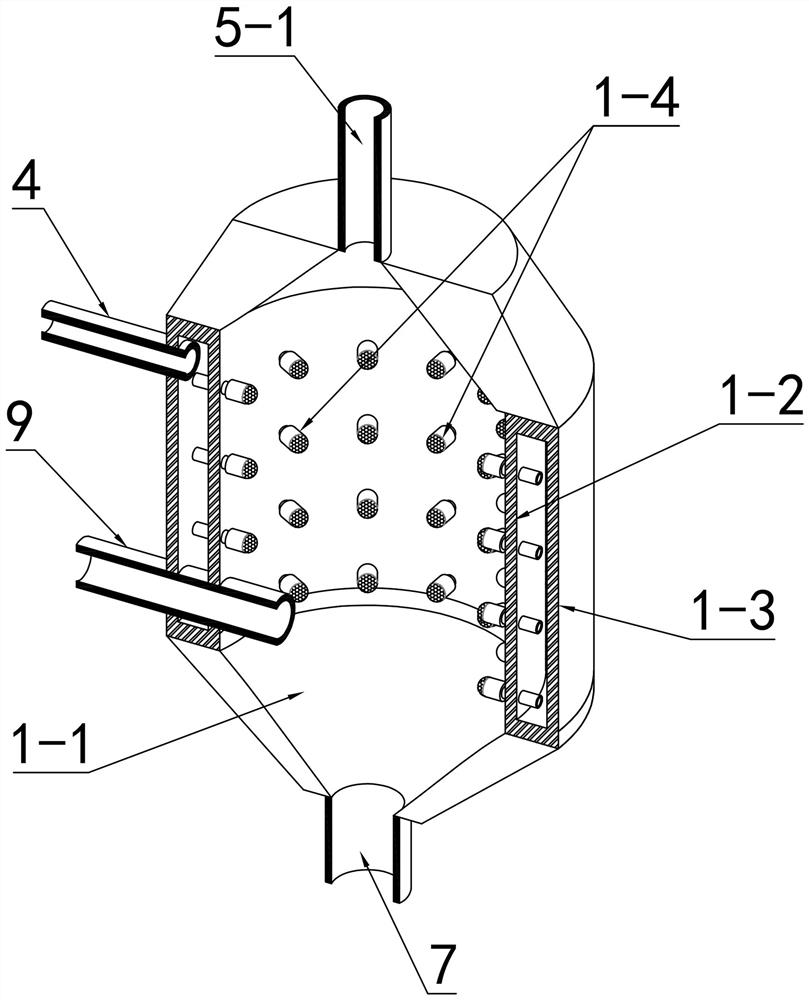

[0033] When the corresponding preparation is carried out in the reaction kettle 1, the calcium carbide powder is first blown into the interior of the reaction kettle 1 from the feed pipe 9 with nitrogen, and then through the water inlet pipe 4 to the chamber inner wall 1-2 and the chamber outer wall 1- The space between 3 is filled with the mixed solution, and the mixed solution is finally sprayed into the reaction kettle 1 through the atomizer 1-4, and fully mixed with the calcium carbide powder and reacts to generate acetylene gas, and the completely reacted calcium carbide powder will fall into the storage tank. In the water cavity 1-1, the mixed solution remaining in the water storage cavity 1-1 continues to react to generate gas, and the generated mixed gas is finally output by the first gas delivery pipe 5-1.

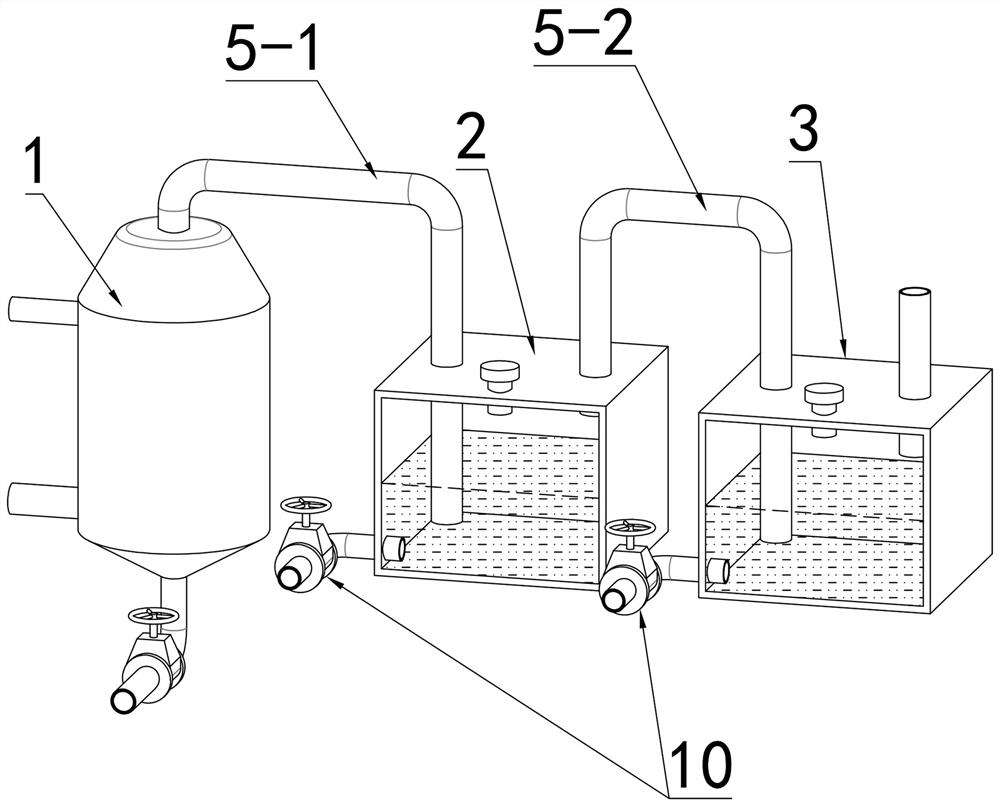

[0034] The preferred solution is as image 3 As shown, the bottom of the filter box 2 is connected to the first liquid discharge pipe 8-1, the bottom of the dryin...

Embodiment example

[0037] A production method of a high utilization rate acetylene production system, comprising the following steps during implementation:

[0038] The first step: inject 15% HCI solution into the interior of the filter box 2 through the liquid injection port 11, and then inject a concentrated sulfuric acid solution with a mass fraction of 98.3% into the drying box 3 through the liquid injection port 11.

[0039] Second step: close the stop valve 10 on the waste liquid pipe 7, the first liquid discharge pipe 8-1 and the second liquid discharge pipe 8-2, and make the filtered solution in the filter box 2 and the drying box 3 not pass through the second step The air outlet ends of the first air delivery pipe 5-1 and the second air delivery pipe 5-2.

[0040] Step 3: inject a mixed solution between the cavity walls of the reactor 1 through the water inlet pipe 4, the composition of the mixed solution is respectively: 35% NaCl solution, 55% NaOH solution and 10% pure aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com