High-mountain narrow-valley arch dam foundation segmented and staged grouting method

A technology for dam foundation and narrow valley is applied in the field of foundation treatment of high and steep bank slope and bedrock surface of high mountain and narrow valley arch dam foundation, which can solve the problem of damaging cooling water pipes and safety monitoring and burying equipment, increasing the amount of concrete drilling works, and dam body concrete. It can avoid problems such as pouring interference, and achieve the effect of avoiding the amount of heavy concrete drilling, ensuring the pouring quality, and reducing the difficulty of construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Include the following steps:

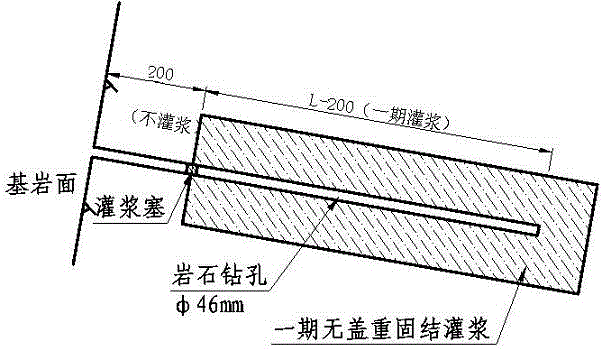

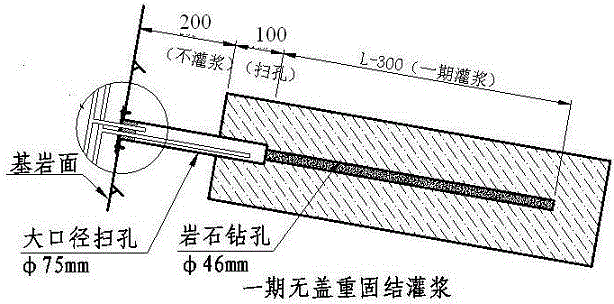

[0038] (1) The first phase of uncapped heavy consolidation grouting

[0039] The first step: drilling, flushing:

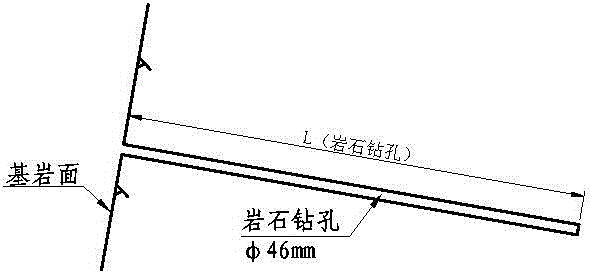

[0040] In the area below 2.0m of the rock surface of the high and steep slopes on both sides of the dam foundation, after the dam foundation is excavated and accepted, the first-stage uncapped heavy-consolidation grouting holes are drilled. The diameter of the first-stage uncapped heavy-consolidation grouting holes is ≥ 46mm depth Lcm;

[0041] The grouting hole should be drilled and flushed before grouting. The thickness of the sediment in the hole should not exceed 20cm. The flushing of the cracks in the consolidated grouting hole should be flushed with pressure water until the backwater is clear. The flushing pressure can be 80% of the grouting pressure. If the value is greater than 1MPa, use 1MPa, and the fissure flushing should be completed 10 minutes after the return water is clarified, and the total time requirement i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com