Concrete warehousing pouring construction equipment and method

A technology of construction equipment and construction methods, which is applied in construction, bridge construction, building construction, etc., can solve the problems of easy blockage of conduits, large pollution, and low work efficiency, and achieve the effect of ensuring quality, excellent quality, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

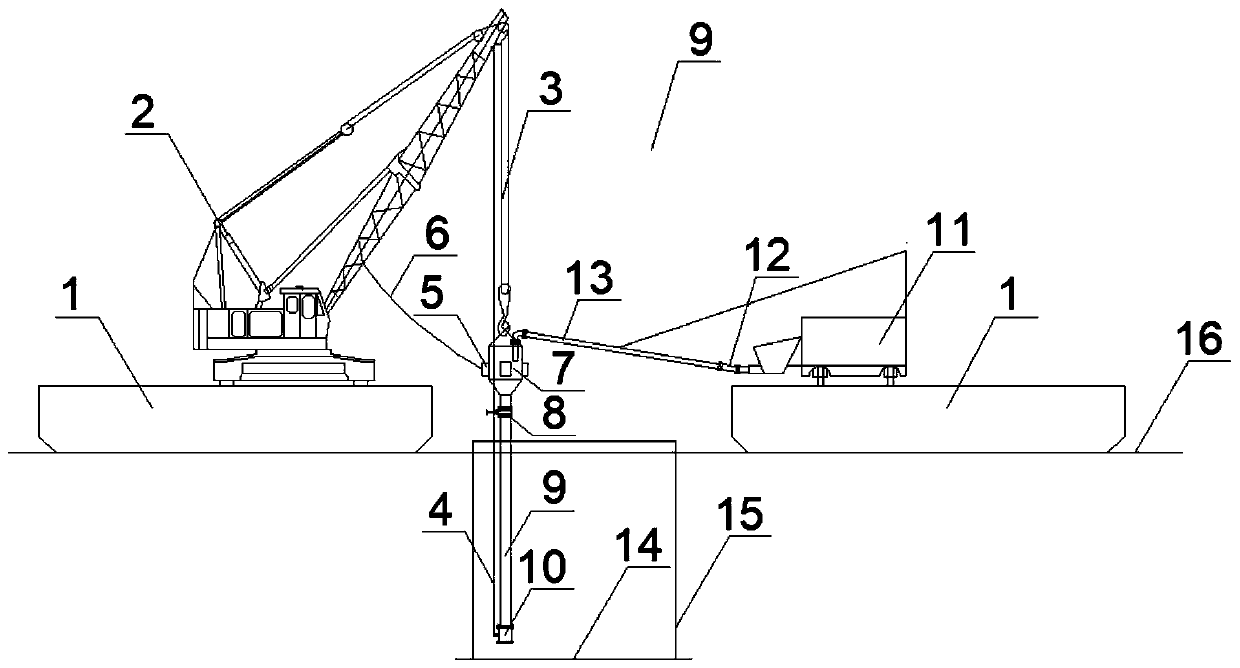

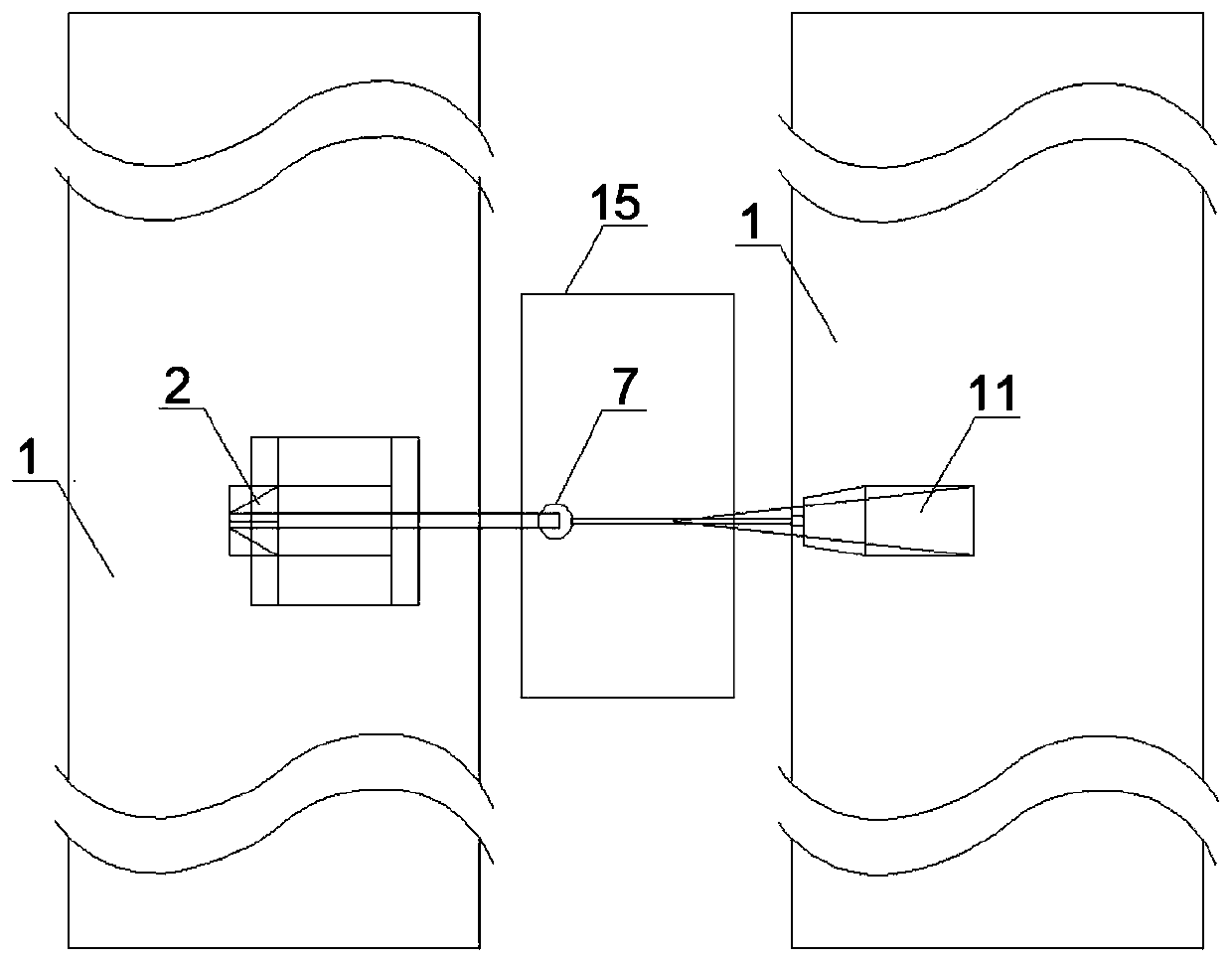

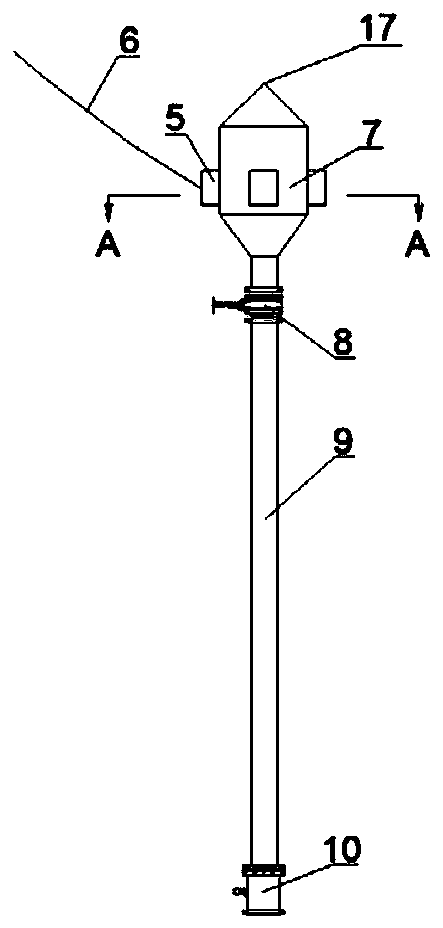

[0035] The construction equipment for pouring concrete into warehouses according to the present invention includes an engineering ship 1, a crane 2, a main winch 3, an auxiliary winch 4, an attached vibrator 5, a vibrator power cord 6, a vibrating hopper 7, and a vibrating hopper valve 8 , conduit 9, conduit valve 10, concrete pump truck 11, braided rubber pipe 12, concrete delivery pipe 13, base 14, formwork 15, water surface 16 and vibrating hopper lug 17. The specific structure and connection method are:

[0036] The engineering ship 1 is provided with a crane 2 and a concrete pump truck 11. The crane 2 includes a main hoist 3 and an auxiliary hoist 4. The main hoist 3 is connected to the vibrating hopper lug 17, the auxiliary hoist 4 is connected to the conduit valve 10, and the auxiliary hoist 4 Control the opening and closing of the conduit valve 10, the vibrating hopper 7 is equipped with an attached vibrator 5, the lower end of the vibrating hopper 7 is connected with ...

Embodiment 2

[0040] A construction method for pouring concrete into silos, comprising the steps of:

[0041] (1) Pre-construction preparation

[0042] According to the volume of poured concrete, prepare cement, sand, gravel and additives, engineering ship 1, crane 2, vibrating hopper 7, concrete pump truck 11, measuring instruments, and determine the capacity of vibrating hopper 7 and conduit valve 10 according to the construction conditions Diameter, delivery flow rate of concrete pump truck 11;

[0043] (2) Equipment and personnel are in place

[0044] The engineering ship 1 is positioned, the concrete pump truck 11 on the engineering ship 1 is moved to a suitable position, the concrete delivery pipe 13 is put down, the crane 2 positions the vibrating hopper 7 and the conduit 9 to the predetermined pouring position, and the pipe of the concrete delivery pipe 13 The outlet is docked with the vibrating hopper 7, the control room of the crane 2 can control the vibration of the vibrating h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com