Flat die and stand die combined product line for producing wallboard

A production line and combination line technology, applied in the direction of mixing operation control, mixing operation control device, control device, etc., to achieve the effects of accelerating pouring speed, high production efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

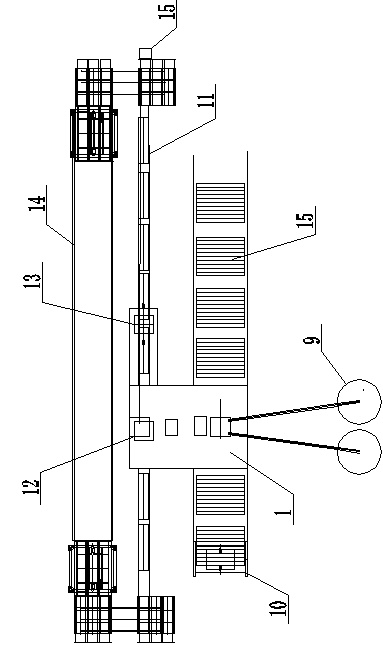

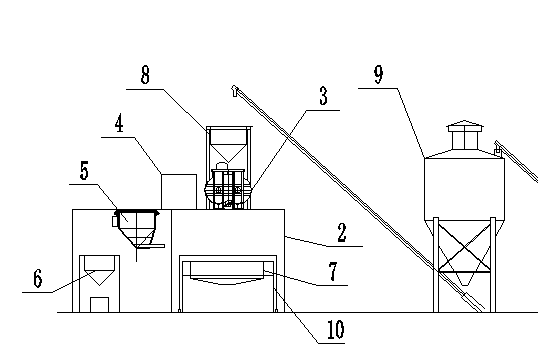

[0026] There are multiple sensors on the console 2, which are respectively installed in the discharge device of the flat mold casting production line; the water supply metering device of the combined line feeding device 1; 8 electronic metering hoppers; the joint of the laterally moving slurry hopper 5 and the mixer 3 ; Transverse movement of the slurry hopper 5 and vertical mold silo 7, flat mold silo 6 docking; flat mold mold in place.

[0027] The water supply metering device is communicated with the mixer 3, and the water supply metering device is connected with a water supply source through a water pipe.

[0028] The combined line feeding device 1 is provided with an electric control system, and is connected with the feeding machine, the water supply metering device, the mixer 3, the foaming machine 4, the vertical mold silo 7, the flat mold silo 6 and various sensors.

[0029] The production line is also equipped with an information control center connected to the flat m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com