Fixed bed production device for continuously producing 1, 4-cyclohexanedicarboxylic acid and use method

A technology for cyclohexanedicarboxylic acid and a production device, which is applied in the field of a fixed-bed production device for continuous production of 1,4-cyclohexanedicarboxylic acid, can solve problems such as cumbersome processes, and achieves simple process setting and control system, and high energy efficiency. Low consumption and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

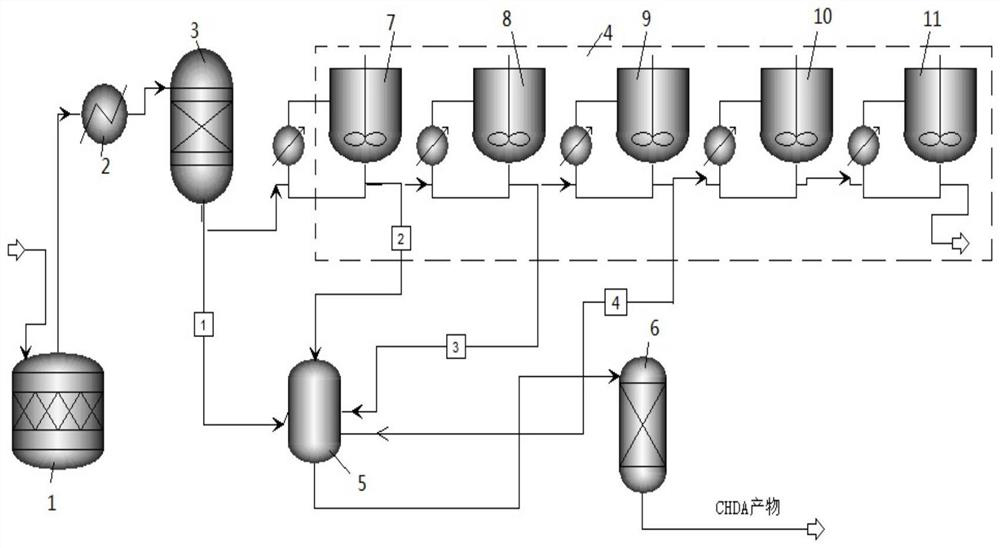

[0039] Such as figure 2 As shown, the TPA solution made by oxidation reactor 1, heat exchange dissolver 2 and refining reactor 3 is used as raw material TPA;

[0040] The prepared TPA aqueous solution with a concentration of 30% is introduced into the TPA solution storage tank 5 through the diversion line 1, and the TPA solution in the storage tank is kept in a liquid state by steam tracing. The split ratio of the split line is 3%, and the split ratio of the remaining split lines is 0%;

[0041] The raw material TPA in the TPA solution storage tank 5 is introduced into the fixed-bed hydrogenation reactor 6 to produce 1,4-cyclohexanedicarboxylic acid CHDA; the hydrogenation reactor temperature is 250°C, the pressure is 7MPa, and the conversion rate of TPA is 99.5 %, CHDA yield 98%.

Embodiment 2

[0043] Such as figure 2 As shown, the TPA solution after the first crystallizer 7 of the first crystallizer 7 of the crystallizer group 4 is introduced as raw material TPA by the TPA solution that oxidation reactor 1, heat exchange dissolver 2 and refining reactor 3 make;

[0044] The TPA aqueous solution with a concentration of 12% is introduced into the TPA solution storage tank 5 through the diversion line 2, and the TPA solution in the storage tank is kept in a liquid state by steam tracing. The temperature of the storage tank is 290 ° C, and the pressure is 40 Bar. The split ratio of the split line is 2%, and the split ratio of the remaining split lines is 0%;

[0045]The raw material TPA in the TPA solution storage tank 5 is introduced into the fixed-bed hydrogenation reactor 6 to produce 1,4-cyclohexanedicarboxylic acid CHDA; the hydrogenation reactor temperature is 250°C, the pressure is 8MPa, and the conversion rate of TPA is 99.8 %, CHDA yield 98.4%.

Embodiment 3

[0047] Such as figure 2 As shown, the TPA solution made by oxidation reactor 1, heat exchange dissolver 2 and refining reactor 3 is introduced into the TPA solution after the first crystallizer 7 and the second crystallizer 8 of crystallizer group 4 as raw material TPA;

[0048] The prepared TPA aqueous solution with a concentration of 3.7% is introduced into the TPA solution storage tank 5 through the diversion line 3, and the TPA solution in the storage tank is kept in a liquid state by steam tracing. The temperature of the storage tank is 260 ° C, and the pressure is 40 Bar. The split ratio of the split line is 1%, and the split ratio of the remaining split lines is 0%;

[0049] The raw material TPA in the TPA solution storage tank 5 is introduced into the fixed-bed hydrogenation reactor 6 to produce 1,4-cyclohexanedicarboxylic acid CHDA; the temperature of the hydrogenation reactor is 250°C, the pressure is 7-8MPa, and the conversion rate of TPA 99.9%, CHDA yield 98.3%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com