Precise aluminum profile extrusion forming equipment

A technology of extrusion molding and aluminum profiles, applied in the direction of metal extrusion, metal extrusion dies, metal processing equipment, etc., can solve the problems of energy waste, reduce work efficiency, etc., to avoid dangerous accidents, save energy, and improve material utilization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

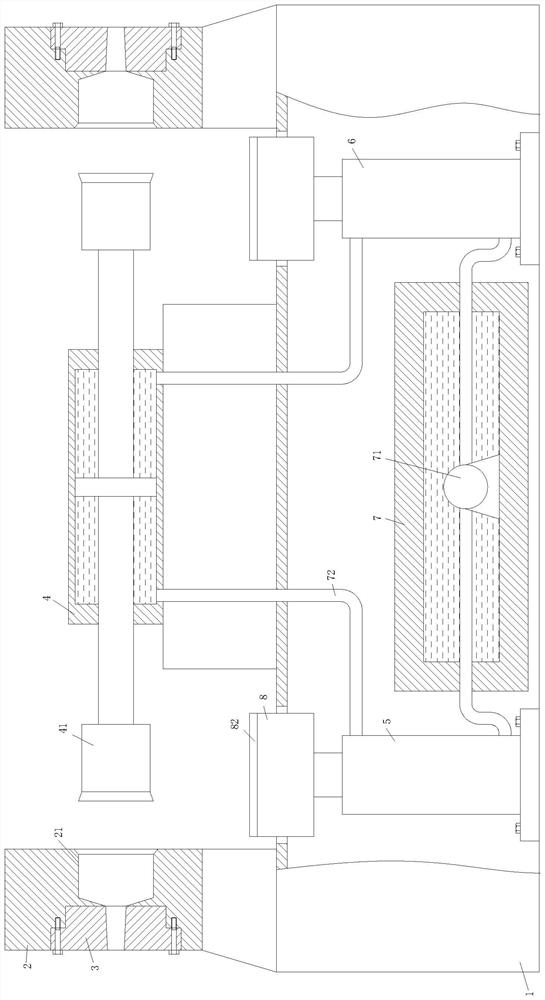

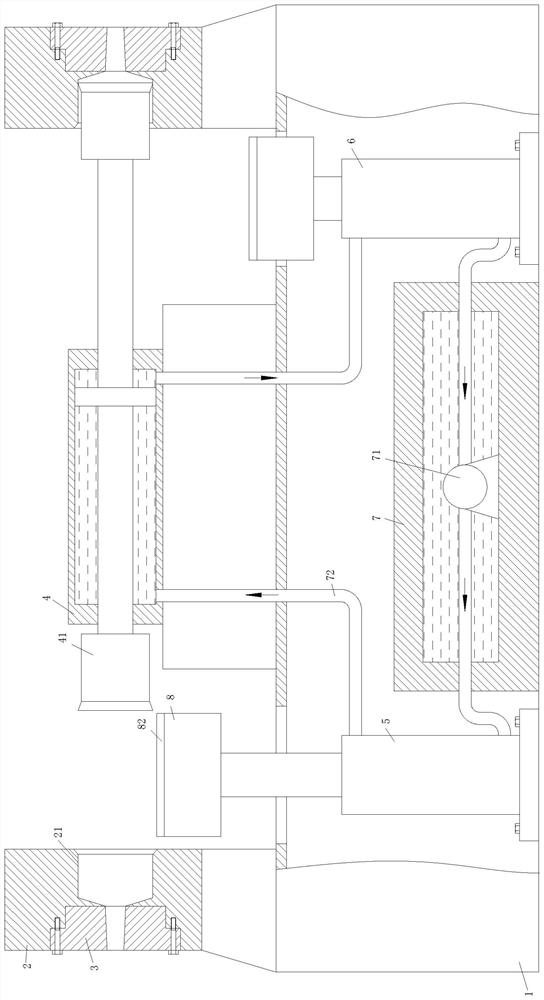

Method used

Image

Examples

Embodiment approach

[0046] As an embodiment of the present invention, the hose 72 is a steel wire braided hose;

[0047] The steel wire braided hose 72 has high pressure resistance and corrosion resistance, which can ensure the safety of the A hydraulic cylinder 5, the B hydraulic cylinder 6 and the two-way hydraulic cylinder 4 during high pressure operation, and avoid high pressure cracking of the oil circuit.

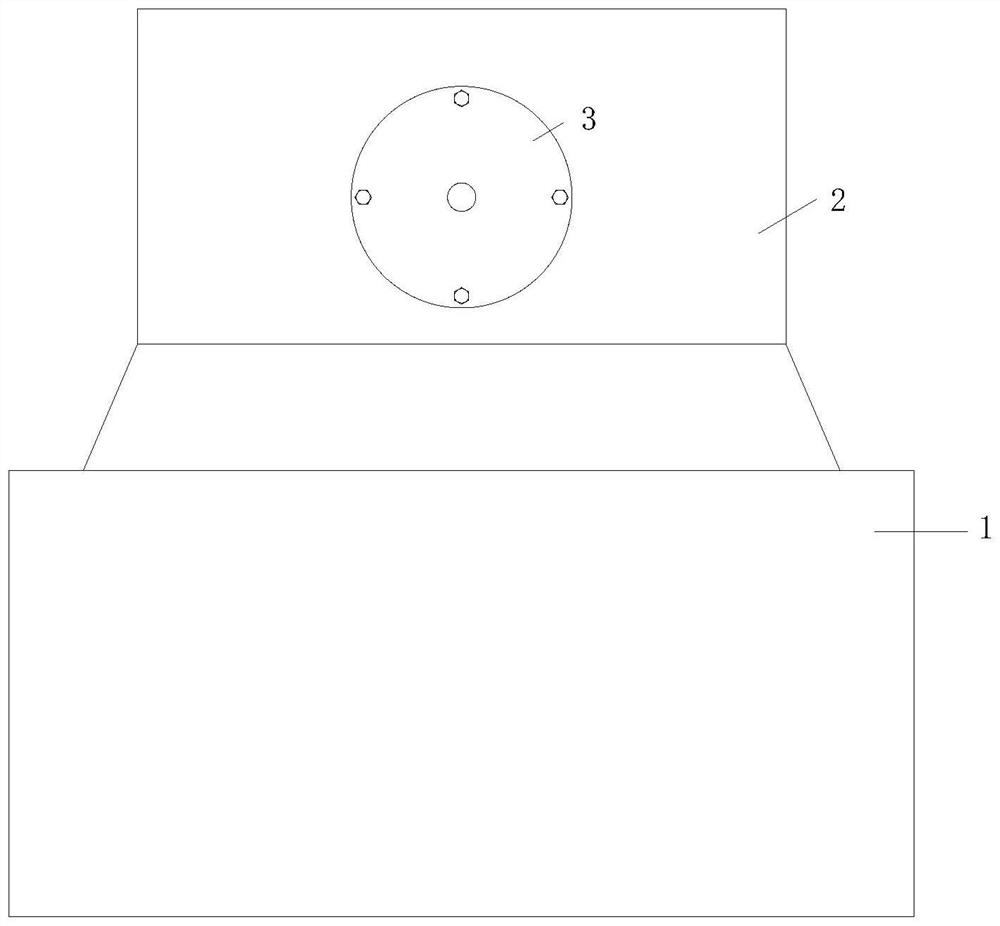

[0048] As an embodiment of the present invention, the tops of the hydraulic rods of the A hydraulic cylinder 5 and the B hydraulic cylinder 6 are fixed with a material holder 8, and the top of the material holder 8 is elastically connected with a supporting plate 82 through a spring 81, and the top radian of the supporting plate 82 is the same as this The radian of the outer wall of the aluminum rod used in the invention is the same;

[0049] As an embodiment of the present invention, the support plate 82 is made of die steel;

[0050] In the actual use process of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com