Device for expanding pouring range of ground pump distributing machine

A spreader and range technology, which is applied in the field of equipment to expand the pouring range of the ground pump spreader, can solve the problems affecting the construction period and concrete quality, the dead angle of the sky pump pouring surface, and the inability to use automobile pumps, etc., so as to make up for the limitations and reduce The effect of labor and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

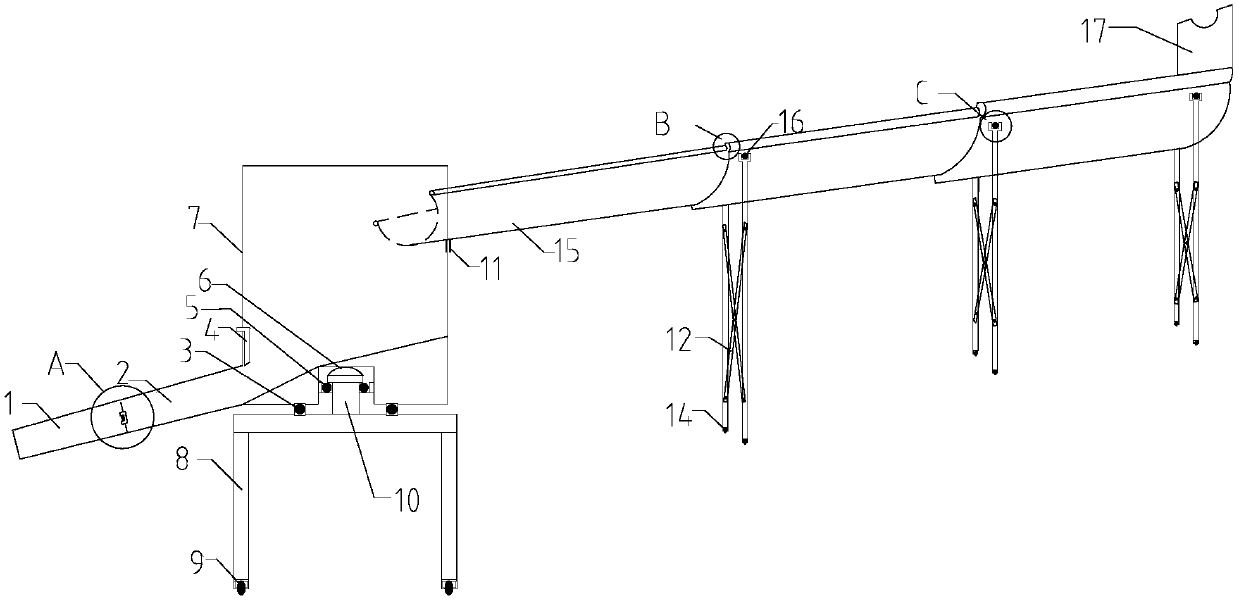

[0026] like Figure 1-7 As shown, the device used to expand the pouring range of the ground pump distributor in the present invention includes a telescopic chute 15, a distribution bucket 7 and a sliding track.

[0027] The telescopic chute 15 is spliced by a plurality of chutes 15, the bottom of the telescopic chute 15 is connected with the shear brace 12 through the bolt 16, the bottom of the shear brace 12 is provided with a first universal wheel 14, and the telescopic chute 15 passes through the card Plate 11 is connected with distribution bucket 7 . The end of the telescopic chute 15 is provided with a pipe clamping notch 17 for fixing the pipe head and controlling the discharge direction.

[0028] A slide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com