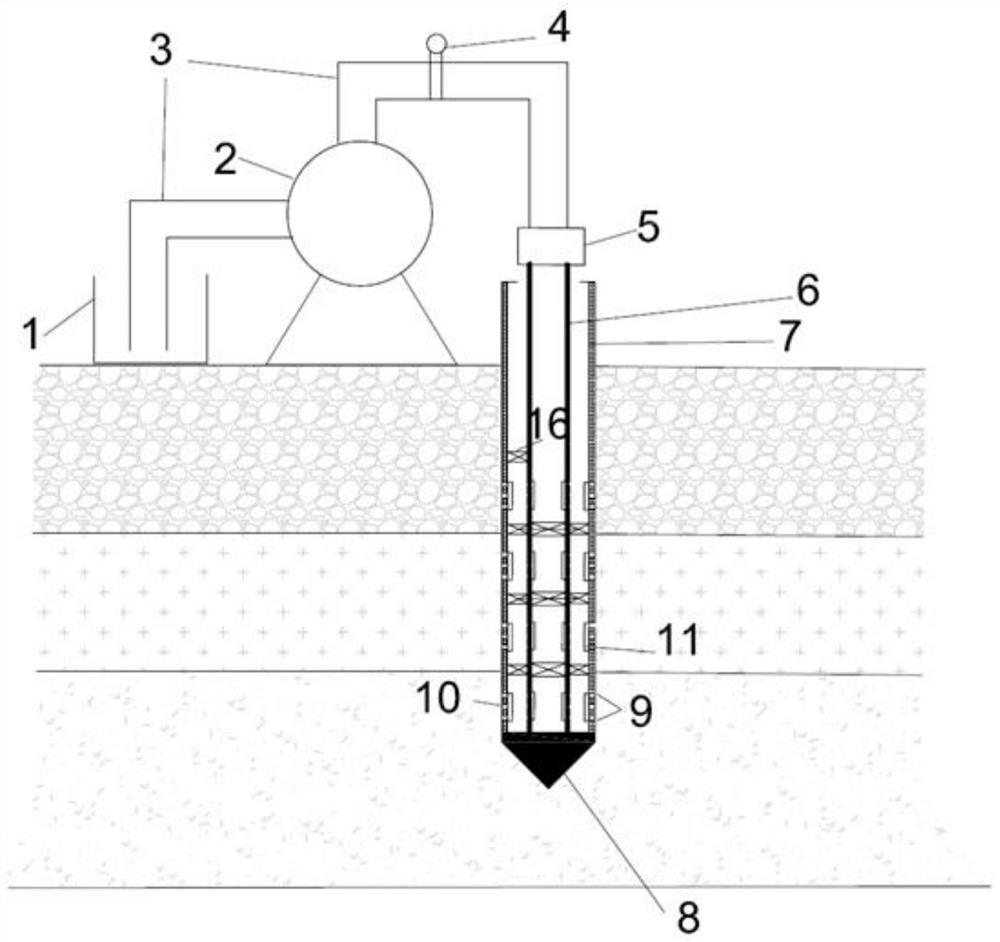

Layered double-channel underground grouting structure and method

A dual-channel, operating method of technology, applied in the field of grouting reinforcement of soft soil foundations and anti-seepage plugging, can solve the problems of grouting hole blocking, grouting hole being easily blocked, high calcium carbonate output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

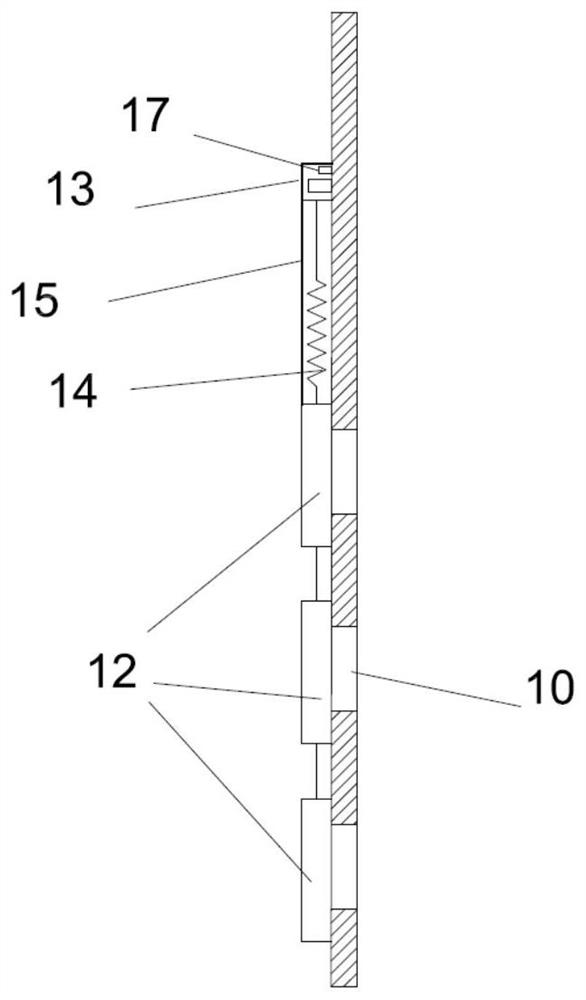

[0030] Such as Figure 1-2As shown, a layered double-channel underground grouting structure is disclosed in this example. The liquid reservoir 1 is made of a large plastic bucket, and the capacity can be adjusted in real time according to the preset grout volume. The inner diameter of the PE hose 3 is 32 mm, one end of which is placed on the bottom of the liquid reservoir, and the other end passes through the constant pressure water pump 2 and is connected to the pipe joint 5 . An electromagnetic flowmeter 4 is arranged on the PE hose 3 . The constant pressure water pump 2 can adjust the grouting pressure, and can adopt a suitable grouting pressure for areas to be grouted with different depths and different permeability....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com