Novel grouting drill pipe and use method thereof

A drill pipe and grouting technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve problems such as engineering waste, and achieve the effects of ensuring construction safety, reducing construction costs and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] As an embodiment of the present invention, the grouting method includes two methods:

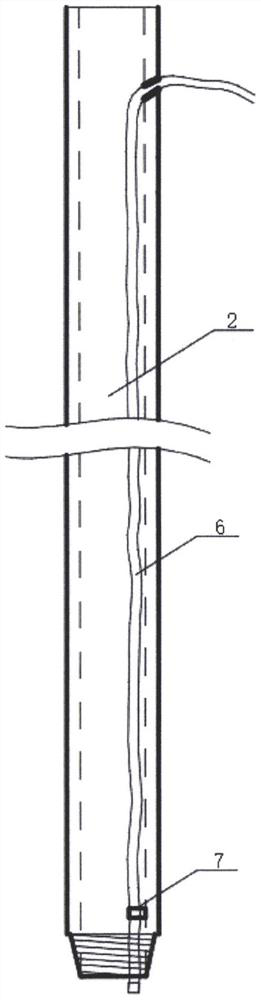

[0047] ①Advance grouting, specifically, after drilling a certain distance, the drill is pulled out, a new type of grouting drill pipe is lowered, the air bag 10 is inflated to the design pressure, grouting is performed on the target hole section, and the drill pipe is pressed by water after grouting. The inner grout is replaced, the new grouting drill pipe is pulled out, the drill is lowered and the drilling is continued, and the above steps are repeated to complete the grouting of the entire borehole.

[0048] ②Backward grouting, specifically, the drilling is completed at one time. After drilling to the design hole depth, the drill is pulled out. After the grouting hole section is determined, a new type of grouting drill pipe is lowered, and the air bag 10 is inflated to the design pressure. Grouting, pressurize water after grouting to replace the slurry in the drill pipe, connect th...

Embodiment example

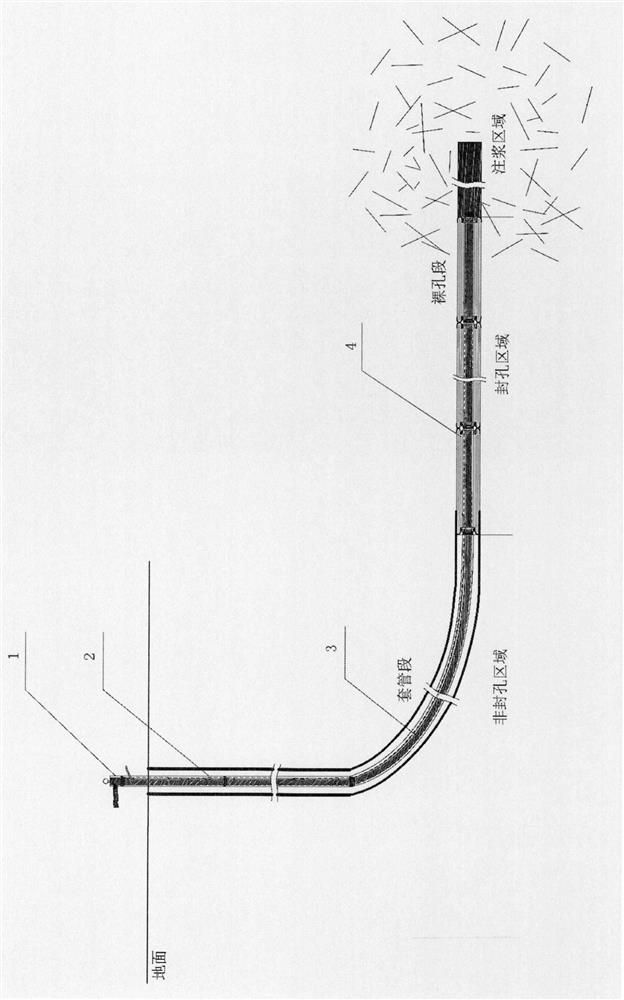

[0050] In the actual operation of the forward and backward grouting methods, the operation steps used in the present invention are the same, so this time the 1600m hole depth is used as an example to describe, and the casing depth is 800m, and the grouting hole section is selected to be 1500-1600m.

[0051] Step 1: After drilling to the target hole section, select the grouting hole section, and pull out all the drill pipes in the hole.

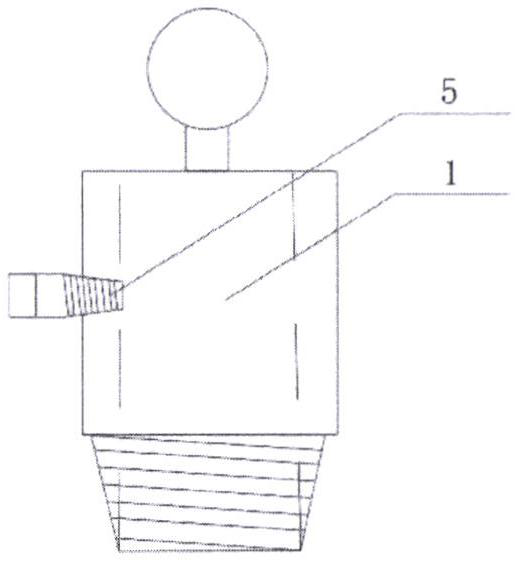

[0052] Step 2, the sealing area is 700m-1500m, and 800m is selected for description this time. Select the number of three-stage grouting drill pipes, connect and install them, and run them one by one; determine the orientation when running in, that is, the side of the three-stage grouting drill pipe with wear-resistant rubber must be at the bottom of the horizontal section hole,

[0053] Step 3: After the previous drill pipe is lowered into the hole, it is stuck on the slips of the operating table. After the power head lifts the next drill pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com