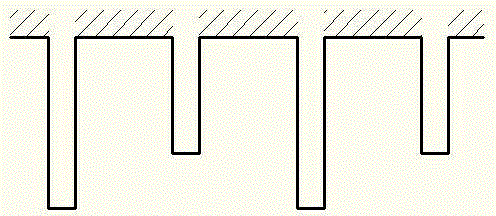

High-pressure gas multistage pre-splitting grouting transformation method for surrounding rock of deep soft rock roadways

A high-pressure gas and high-pressure air technology, used in tunnels, mining fluids, tunnel linings, etc., can solve problems such as poor injectability and poor grouting effect, achieve outstanding results, high on-site direct application value, and improve injectability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

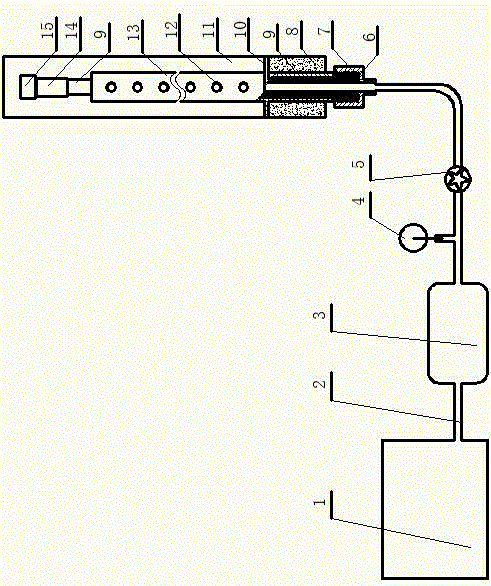

Method used

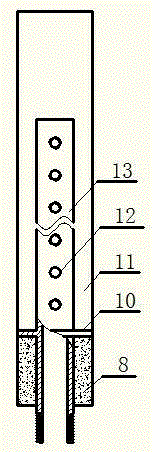

Image

Examples

Embodiment 1

[0055] Example 1: A mine in Shandong Province mainly mines 3 coals, the average thickness of which is 7.78m, and fully mechanized caving mining is used to mine full height at one time. The -650 level south wing roadway is the horizontal development roadway of the mine. Due to the influence of the fault structure, the roadway passes through multiple mudstone layers during the excavation process. The buried depth of the main road is about 700m, the section shape is a straight wall and semicircular arch, the wall height is 1.8m, the arch height is 2.4m, and the clear width is 4.8m. Initially, anchoring and grouting support is used as permanent support. Since the cracks in the surrounding rock of the roadway are not developed, and the existing cracks are closed under the action of the ground stress, the grouting effect is very poor. Three months after the construction of the roadway, the deformation and damage were serious, and the section of some sections shrank by more than 80%....

Embodiment 2

[0065]Example 2: The floor elevation of a three-level roadway in a mine in Huaibei is -1000m, the roadway is located on the 10th coal floor, and the lithology is siltstone and mudstone. Affected by the deep high ground stress, the surrounding rock of the roadway is seriously deformed and damaged. The shape of the cross-section is a straight wall semi-circular arch, with a wall height of 1.8m, an arch height of 2.35m, and a clear width of 4.7m. Initially, anchoring and grouting support is used as permanent support. On-site detection shows that the roadway surrounding rock joints and fissures are well developed, but under the action of high ground stress, most of the fissures are closed, and the effect of grouting reinforcement is not good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com