Composite superfine cement grout slurry and preparation method thereof

An ultra-fine cement and grouting technology, applied in the field of mine and underground engineering safety, can solve the problems of lack of pertinence and specificity of ultra-fine cement grouting, buried engineering hidden dangers, and little research, etc., and achieves impermeability and The effect of good volume stability, low cost, high fluidity and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical content of the present invention, specific examples are cited and described as follows.

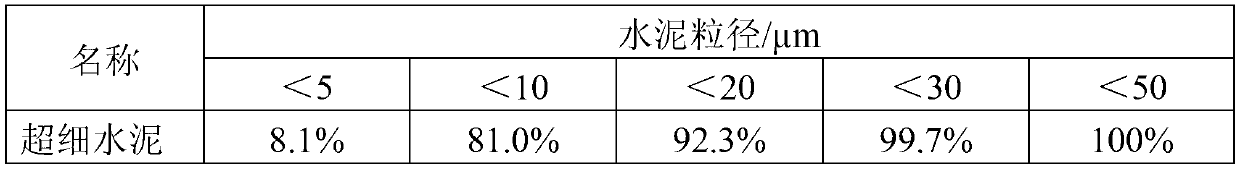

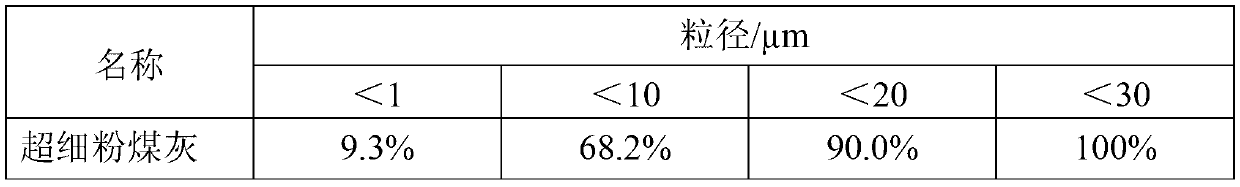

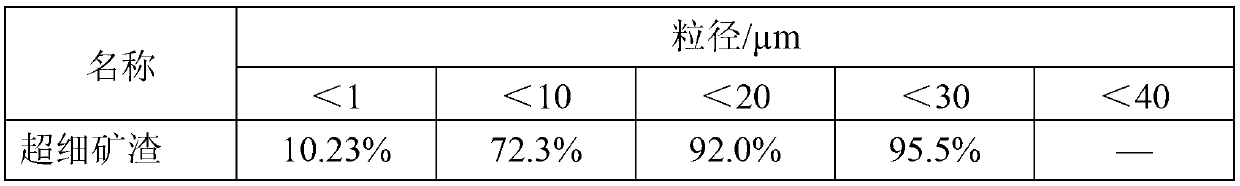

[0019] The composite ultra-fine cement grouting slurry of this embodiment is prepared by ball milling the ultra-fine composite grouting material from the matrix component and the external component, and then the slurry is prepared according to the predetermined water-cement ratio. The matrix component includes ordinary Portland cement, Fly ash, slag and water, external components include grinding aids, active activators, composite high-efficiency water reducers, expansion agents and retarders. Wherein, the mass ratio of ordinary Portland cement and fly ash is 3:2, based on the total mass of ordinary Portland cement and fly ash, the composite ultrafine cement grouting slurry contains the following components in mass percentage: The slag content is 10% of the aforementioned total mass, the composite high-efficiency superplasticizer is 0.8% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com