Coal mine underground reservoir and multi-layer grouting anti-seepage reinforcement method for reservoir dam

An underground reservoir, multi-level technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of coal pillar dam body soaked in water for a long time, uneven tearing of geotextile, affecting the anti-seepage performance of dam body, etc. To achieve the effect of mitigating major coal mine flood accidents, strengthening and anti-seepage effect, and safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

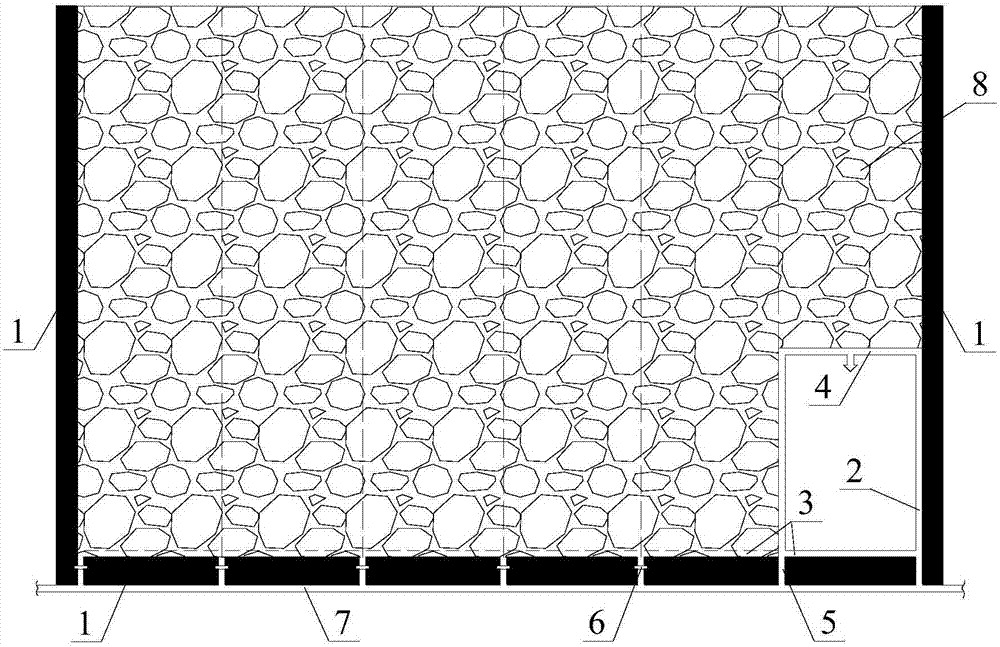

[0039] The aquifer above the coal seam of a coal mine is 0.10m~27.48m, with an average of 8.24m. The goaf continuously receives surface water, loose aquifer water and bedrock aquifer water. The normal water inflow of the mine is 486m 3 / h, mine hydrogeological type is medium.

[0040] Considering the calculation of the water storage coefficient, it is determined that a complete coal mine underground reservoir will be constructed from the goaf of six working faces. The roadways 2 on both sides of the underground reservoir and the retraction roadway 3 are rectangular cross-sections. The height of the roadway is 4.4m, and the width of the coal pillar dam is 30m. .

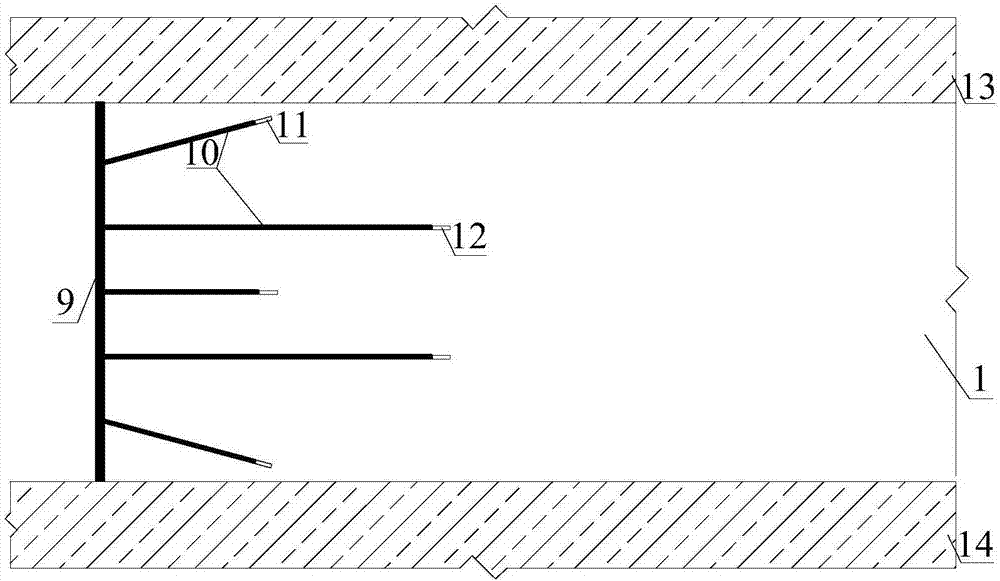

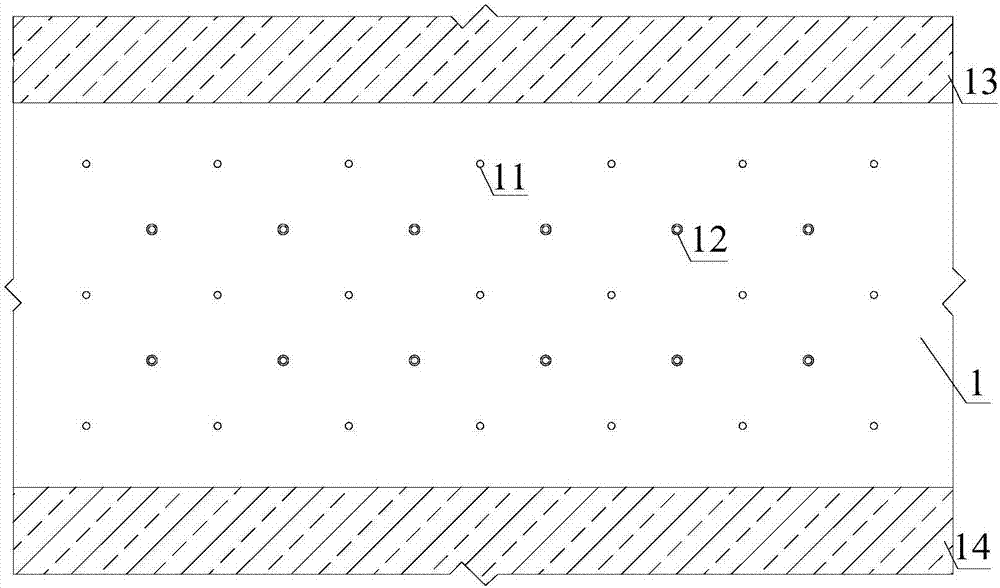

[0041] After the roadways 2 on both sides of the underground reservoir and the retraction roadway 3 are excavated, anchor the formed roadway wall in time, and immediately spray concrete grout on the roadway wall between the overlying rock layer 13 and the underburden rock layer 14 after anchoring, and wait for the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com