Segmented hollow grouting anchor cable and using method thereof

A grouting anchor cable and segmented technology, which is applied in the direction of earth drilling, bolt installation, mining equipment, etc., can solve the problem of unsatisfactory support, uneven grouting, and inability to strengthen the deep surrounding rock by segmented grouting To achieve the effect of strengthening full-length anchorage, improving safety effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

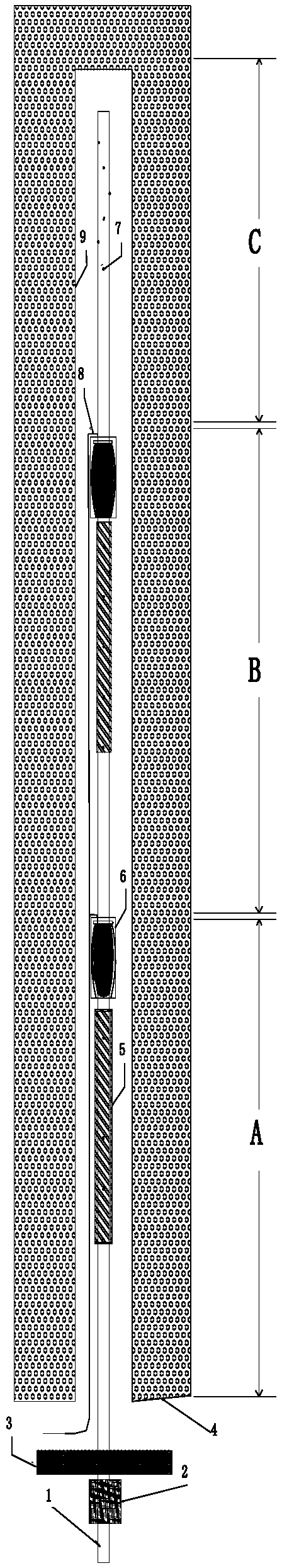

[0034] As an embodiment of the present invention, there are two segmented hole sealing devices, which divide the cable body 1 into three areas, namely the grouting area A, the grouting area B, and the grouting area C. A is the tail end of the cable body 1 to the top of the fixing frame 6 of the first hole sealing device, B is the top of the fixing frame 6 of the first hole sealing device to the top of the fixing frame 6 of the second hole sealing device, C is the top of the fixing frame 6 of the second hole sealing device From the top of the fixing frame 6 of the two sealing devices to the front end of the cable body 1; the grouting sequence is from section C-section B-section A.

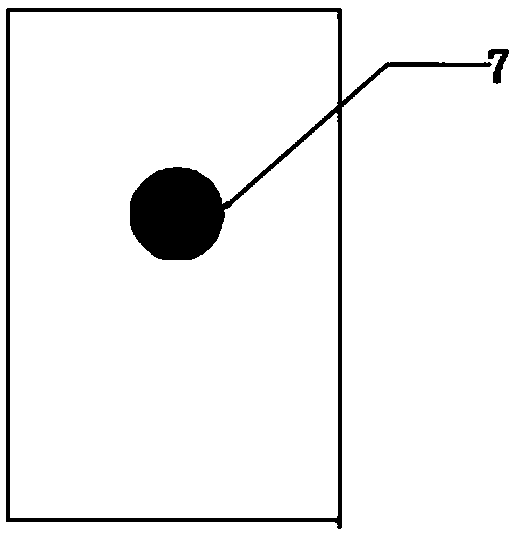

[0035] There is a through grouting hole in the cable body 1; a grout hole is provided at the cable body corresponding to the sealing device, and there is lubrication between the sealing plug 7 and the grout hole of the cable body 1 so that the sealing plug can Moving up and down along the cable body...

Embodiment 1

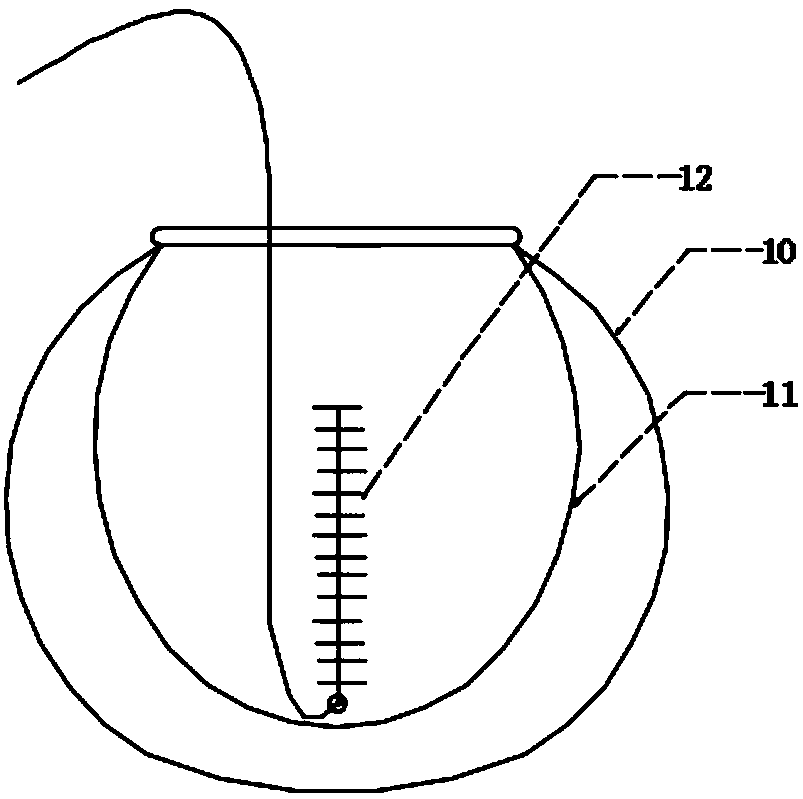

[0046] A1, assemble the segmented hole sealing device: open the inner slurry bag 11 partly, set the nylon hook and loop 12 at the opening, and the upper end of the nylon hook and loop 12 is connected with the operating rope 8, so that the operating rope 8 can pull the nylon stick in the future. Buckle 12, inside solid slurry bag 11 packs into chemical slurry A, and outside solid slurry bag 10 packs into chemical slurry B. The inner slurry bag 11 is connected with the outer slurry bag 10 by means of rope joints, and the operating rope 8 is drawn out from the rope joints so that it can be freely operated without being affected. Tie the rope joint between C and B and the reserved area between B and A to make it stable, install the fixing frame 6 tighter nuts, and complete the installation of the segmented hole sealing device.

[0047] A2, seal the slurry hole: apply lubricant on the sealing plug 7, block the slurry hole in the B and A areas, put a thicker sleeve 5 on the A area, ...

Embodiment 2

[0051] Embodiment two: (the second sealing method)

[0052] B1, Assemble segmented hole sealing device: adjust 0.9~1.3kg / m static expansion agent with appropriate amount of water to form a fluid slurry, put the mixed fluid slurry into the external solid slurry bag 10, and put the rope joint Tie it between C and B and the reserved area between B and A to make it stable, install the fixing frame 6 tighter nuts to ensure its tightness, and complete the installation of the segmented hole sealing device.

[0053] B2, seal the slurry hole: apply lubricant on the sealing plug 7, block the slurry holes in the B and A areas, put a thicker sleeve 5 on the A area, and put a thinner sleeve on the B area Tube 5, to ensure its tightness.

[0054] B3, Drilling: Drill holes 9 for the required support in the roadway, reserve the lengths of the pre-determined C and B grouting areas in the front section of the cable body, and between C and B and between the lengths reserved for B and A Simulta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com