Casting gating system

A pouring system and pouring cup technology, which is applied in the field of sand casting, can solve the problems of unfavorable molten iron casting yield, increase of return material, increase of molten iron buffer pit volume, etc., so as to reduce internal defects, improve casting yield and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

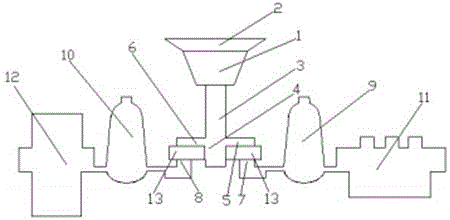

[0009] Example: According to figure 1 As shown, a casting pouring system includes a sprue cup 1, a buffer pit 2 is arranged above the sprue cup 1, and a main runner 3 is connected to the bottom of the sprue cup 1, and the main sprue 3 The bottom end of the T-shaped tee 4 is provided with a T-shaped tee 4, the gate at the right end of the T-shaped tee 4 is connected with the first runner 5, and the gate at the left end of the T-shaped tee 4 is connected with the second runner 6, so The first runner 5 is connected to the first sprue 7, the second runner 6 is connected to the second sprue 8, the first runner 7 is connected to the first riser 9, and the first riser The port 9 finally communicates with the cavity of the first sand mold 11 , the second sprue 8 is connected with the second riser 10 , and the second riser 10 finally communicates with the cavity of the second sand mold 12 . When the molten iron is poured, it is first poured into the buffer pit 2 and filled quickly. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com