Bean column node unequal strength concrete replacing structure and its construction method

A technology of beam-column joints and concrete, which is applied in the direction of building structure and construction, can solve the problems of slow construction speed and complicated construction technology of beam-column joints, and achieve the effects of simplifying construction technology, speeding up pouring speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

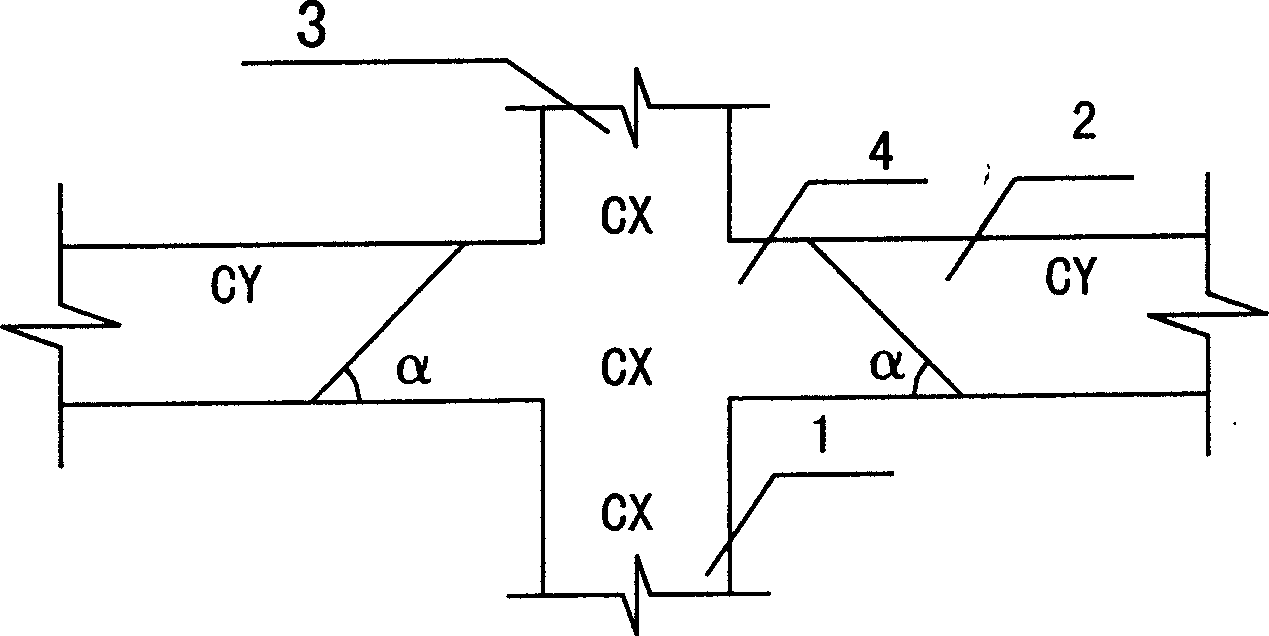

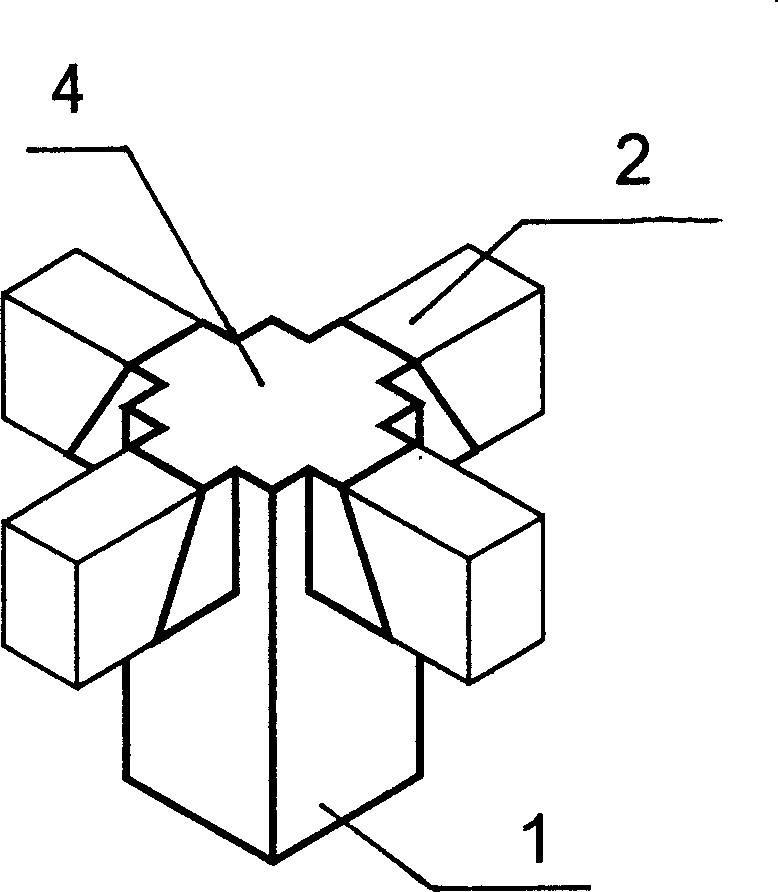

[0029] Embodiment one sees Figure 4 , 5 : The structure is composed of reinforced concrete columns 1 on the upper floor, reinforced concrete beams 2, and reinforced concrete columns 3 on the lower floor to form beam-column nodes 4 at the intersections, and rhombus-shaped enlarged haunches 9 are added around the beam-column nodes to increase thickness, and the side length of the rhombus-shaped enlarged haunches is the same as that of the columns The diagonal of the cross section is vertical. The concrete strength of the enlarged haunch is the same as that of the beam, and the height of the enlarged haunch is the same as the height of the highest beam at the joint. A project is a reinforced concrete frame structure, the concrete strength of the frame column is C40, and the cross-sectional size is 800mm×800mm, the concrete strength of the frame beam is C30, and the cross-sectional size is 400mm×800mm; the rhombus is used to expand the axillary nodes, and the structural reinforc...

Embodiment 2

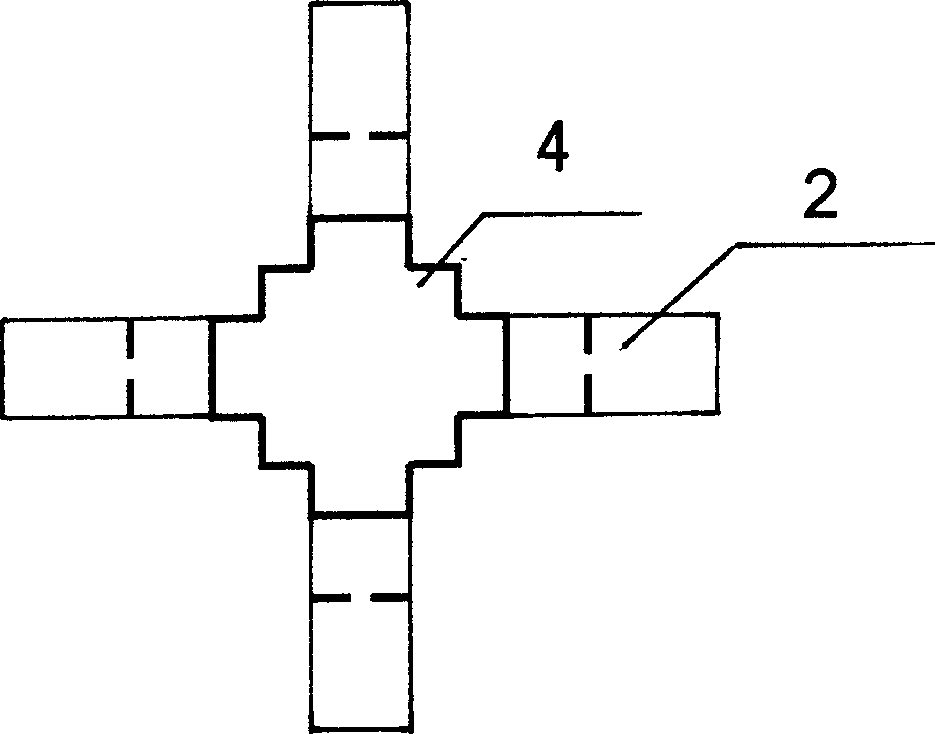

[0031] Embodiment two see Figure 6 , 7 : the shape of the enlarged ax is rectangular, and the side length of the rectangular enlarged ax 10 is parallel to the side length of the column. A project is a reinforced concrete frame structure, the concrete strength of the frame column is C40, and the cross-sectional size is 1000mm×1000mm, the concrete strength of the frame beam is C30, and the cross-sectional size is 400mm×800mm; use rectangular axillary expansion nodes, and the structural ribs are smooth circles with a diameter of 10mm. The side length is 1200mm, the stirrup is threaded, and the diameter is 25mm; the anti-seismic hook length of the structural reinforcement is 100mm, and the hook length of the stirrup is 375mm. At this time, the beam-column joints are poured together with the beam, and the concrete strength grade is C30.

[0032] When the beam-column joints are formed into a rectangular enlarged axillary, the shape of the structural reinforcement is "mouth" shape ...

Embodiment 3

[0033] Embodiment three see Figure 8 , 9 : the shape of the expanded axillary is circular, and the diameter of the circular enlarged axillary 11 is the same as the length of the diagonal line of the column cross section. The local frame column of a certain project has a circular cross-section with a diameter of 800mm, the concrete strength of the frame column is C40, the concrete strength of the frame beam is C30, and the cross-sectional size is 400mm×800mm; the circular enlarged axillary node is used, and the diameter of the circular enlarged axillary part is 1000mm; The structural reinforcement is a smooth circle with a diameter of 10mm, and the stirrup is threaded with a diameter of 25mm; the length of the anti-seismic hook of the structural reinforcement is 100mm, and the length of the hook of the stirrup is 375mm. At this time, the beam-column joints are poured together with the beam, and the concrete strength grade is C30.

[0034] When the beam-column joint is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com