Elevator matched with steam blasting machines

A technology of steam explosion machine and hoist, which is applied in the direction of conveyor, transportation and packaging, etc., which can solve the problems of poor fluidity of biomass raw materials, material retention, and fast turnover of raw materials, so as to improve effective working time and reduce occupied time , Improve the effect of logistics efficiency

Active Publication Date: 2014-09-10

于政道 +1

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the steam explosion of materials is processed one by one, the feeding time is short (5-10 seconds) and the volume is large (2-5 cubic meters), which makes it difficult for general belt conveyors and bucket conveyors to adapt.

The second is the fast pace of raw material turnover. The raw materials transferred from the previous process are immediately put into steam explosion treatment without temporary storage. The raw material transfer does not have time to repeatedly load and unload between various material transfer equipment, and it is required to be transferred in a turnover container. The turnover container volume should be consistent with the single processing volume of the steam explosion machine

The third is that the biomass raw material has poor fluidity and high viscosity, which requires a large dumping angle and a fast dumping speed when the material is fed in, otherwise the material will stay in the conveying container and the dumping will not be clean

The fourth is that biomass raw materials such as straw have low density and fluffy volume, and the lifting power should be controlled within a reasonable range. The unit energy consumption of traditional grain transportation equipment to transport biomass raw materials is too high

In addition, the production environment for processing biomass raw materials is relatively harsh, with a lot of dust, which makes the moving parts such as belt conveyors and other equipment such as bearings and belt rollers prone to failure and unreliable operation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

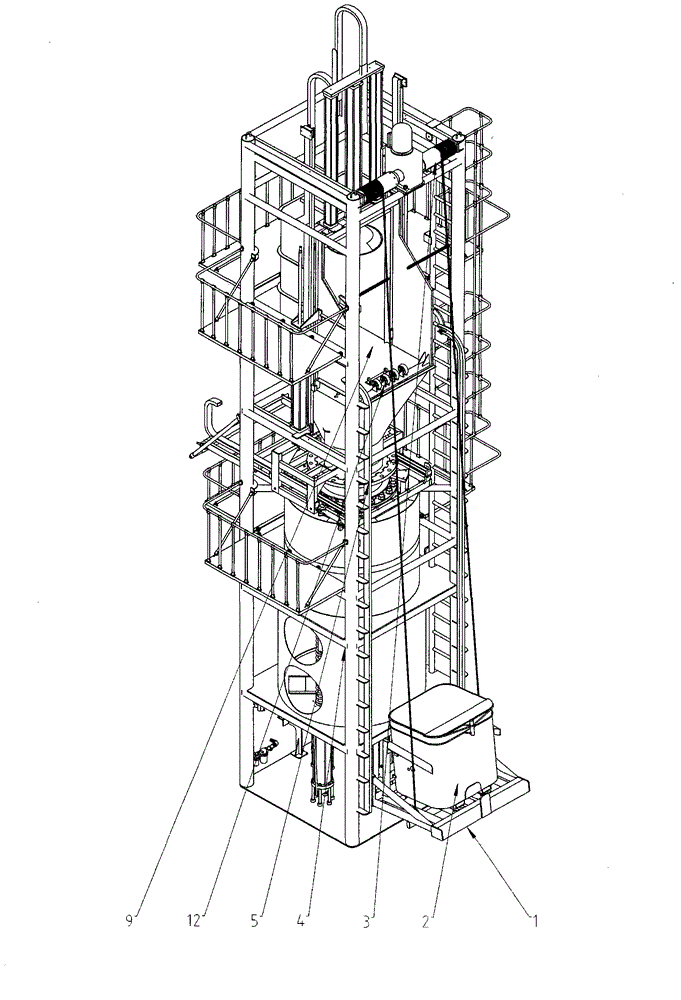

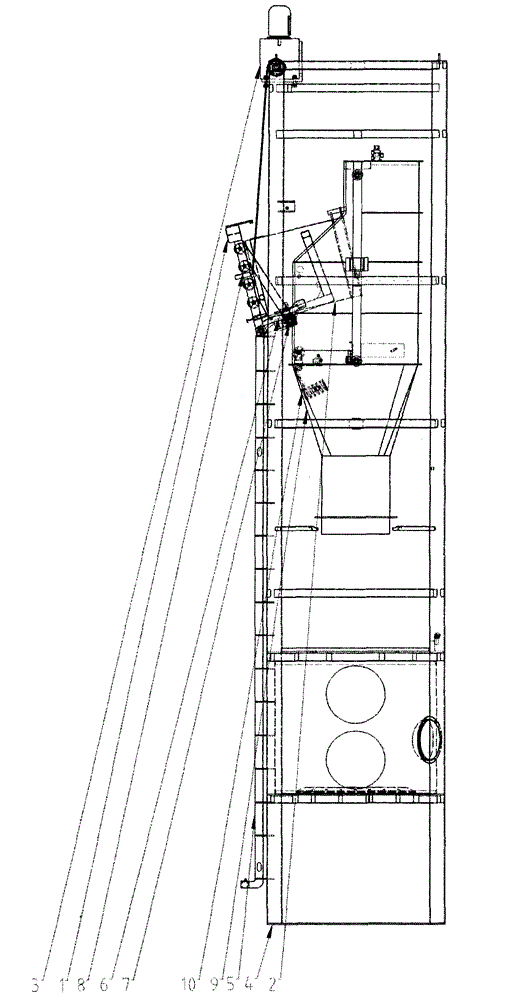

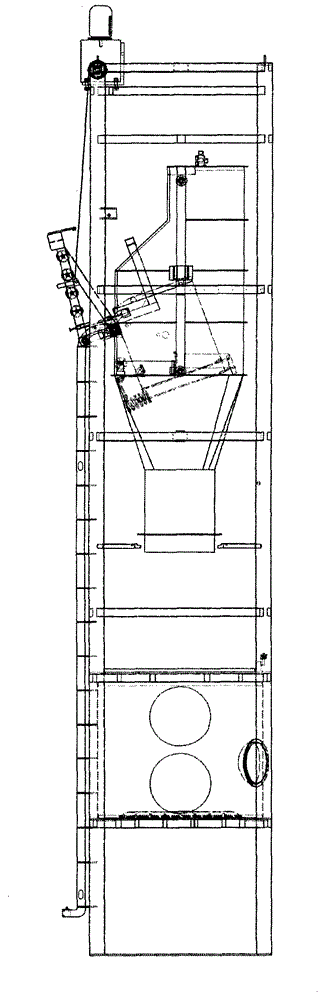

[0023] The supporting hoist on the LB-1500 type numerically controlled continuous steam explosion machine is the specific implementation of the above invention. The elevator has a loading hopper volume of 2.5 cubic meters, a lifting height of 10 meters, a lifting quality of 1 ton of straw or 3 tons of grain, and a power of 11KW, which improves the working efficiency of large and medium-sized industrial continuous steam explosion equipment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a material elevator matched with steam blasting machines, and belongs to material conveying devices. The elevator matched with the steam blasting machine provided by the invention only adopts a steel wire rope roller as a driving component to lift and drag a bracket to move up and down in a vertical track, and can permit a large-size circulating hopper to be dumped for angles of more than 150-170 degrees and reset. Since the dumping angle is more than 150 degrees, dumping speed is rapid, and thereby light biomass can be dumped completely. A steel wire rope is directly used for vertically hoisting materials without any moving accessories, so that additional energy consumption is avoided. The elevator is attached to the vertical frame of the steam blasting machine, thus being capable of saving occupied space as much as possible. In addition, the machine is simple in structure, few in moving parts, and being capable of fully adapting to various kinds of biomass materials and hostile working environments, and stable and reliable in operation. The circulating hopper can be rapidly assembled and disassembled by forklifts, and the plurality of circulating hoppers can be configured, thus being capable f greatly improving whole logistics efficiency.

Description

technical field [0001] The invention relates to a material lifting device matched with a steam explosion machine, which is a material conveying device. Background technique [0002] The steam explosion machine is a kind of equipment used for biomass pretreatment. The objects it deals with include crop stalks, energy crops, organic waste, etc. Since large-scale steam explosion equipment is mostly of vertical design, the height of its feeding port is 10-15 meters, the volume of each treatment is 2-5 cubic meters, and the interval between each treatment is 4-5 minutes, so the requirements for the matching hoist are relatively high. special. First of all, the volume of single conveying material is large. Since the material steam explosion is processed one by one, the feeding time is short (5-10 seconds) and the volume is large (2-5 cubic meters) each time, which makes it difficult for general belt conveyors and bucket conveyors to adapt. The second is the fast pace of raw ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G17/12

Inventor 张百良于政道宋安东徐桂转任天宝

Owner 于政道

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com