Excrement leaking plate pouring equipment for livestock breeding

A technology of manure leakage board and equipment, which is applied to supply devices, ceramic molding machines, manufacturing tools, etc., can solve problems such as the shaking of manure leakage board molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

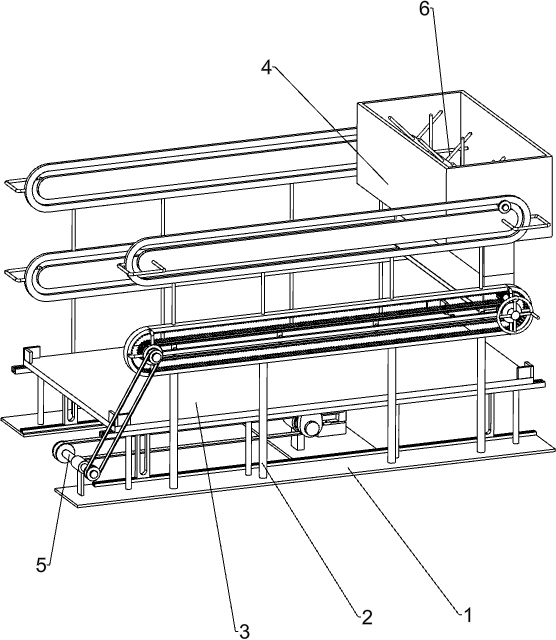

[0024] A kind of dung pouring equipment for livestock breeding, such as Figure 1-7 As shown, it includes a bottom plate 1, a mounting frame 2, a shaking mechanism 3 and a blanking mechanism 4, the front side of the top of the bottom plate 1 is connected with the mounting frame 2, and the top of the bottom plate 1 on the rear side of the mounting frame 2 is equipped with a shaking mechanism 3, and the mounting frame A blanking mechanism 4 is installed between 2 and the bottom plate 1.

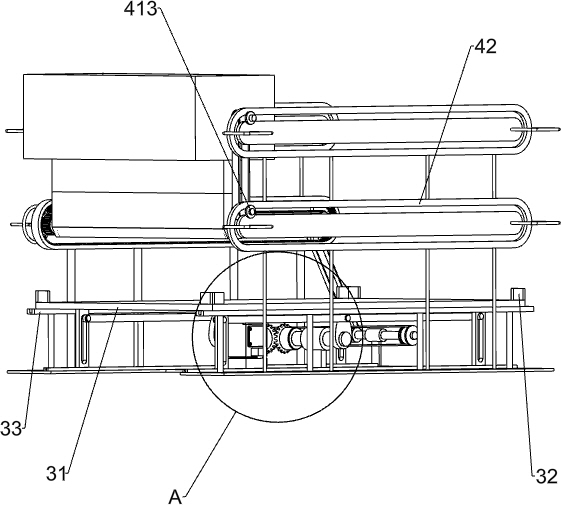

[0025] The shaking mechanism 3 includes a supporting plate 31, a block 32, a guide rail frame 33, a slotted sliding limit plate 34, a first connecting shaft 35, a long connecting rod 36, a cam 37, a second connecting shaft 38, a positioning sleeve 39, a first A bevel gear 310, a second bevel gear 311 and a servo motor 312, two rail frames 33 are connected to the top of the bottom plate 1 on the rear side of the installation frame 2, the two rail frames 33 are front and rear symmetrical, and the...

Embodiment 2

[0029] On the basis of Example 1, such as figure 1 and image 3 As shown, a linkage mechanism 5 is also included, and the linkage mechanism 5 includes a first drive belt set 51, a fourth connecting shaft 52, a fixed collar 53, a second drive belt set 54 and a fifth connecting shaft 55, and the front side rail frame The top of the bottom plate 1 on the left side of 33 is connected with a fixed collar 53, and the fixed collar 53 is connected with a fourth connecting shaft 52 in a rotational manner, and a first connecting shaft 52 is connected between the rear end of the fourth connecting shaft 52 and the front part of the second connecting shaft 38. In the transmission belt set 51, the fifth coupling shaft 55 is connected to the front end of the third coupling shaft 49 on the left side, and the second transmission belt set 54 is connected between the front end of the fifth coupling shaft 55 and the front end of the fourth coupling shaft 52.

[0030] The second connecting shaft ...

Embodiment 3

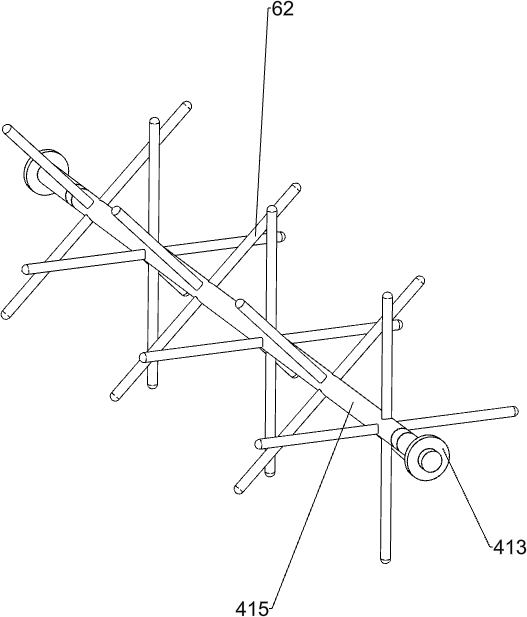

[0032] On the basis of Example 2, such as image 3 and Figure 5 As shown, a stirring mechanism 6 is also included, and the stirring mechanism 6 includes a third transmission belt set 61 and a stirrer 62, the third transmission belt set 61 is connected between the rear part of the rotating shaft 415 and the rear part of the dial shaft 412, and the rotating shaft 415 A plurality of stirring rods 62 are connected evenly spaced above.

[0033] The rotation of the dial shaft 412 can make the rotating shaft 415 rotate through the third drive belt set 61, and the rotating shaft 415 rotates to drive the stirring rod 62 to rotate, and the rotating of the stirring rod 62 can stir the cement slurry in the storage tank 416, so that the storage tank can be prevented from The cement slurry in 416 is agglomerated and agglomerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com