Tightening system of concrete rectangular column formwork and construction method of concrete column

A concrete column and concrete technology, applied in the direction of formwork/formwork/work frame, column, pier column, etc., can solve the problems of time-consuming, low efficiency, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of construction method of concrete column, with reference to figure 1 , including the following steps:

[0050] S1: Formwork 1 is installed, and the standardized concrete formwork 1 is spliced to the outside of the column reinforcement, and the space enclosed by the formwork 1 is closed, and the closed interior forms a concrete pouring space;

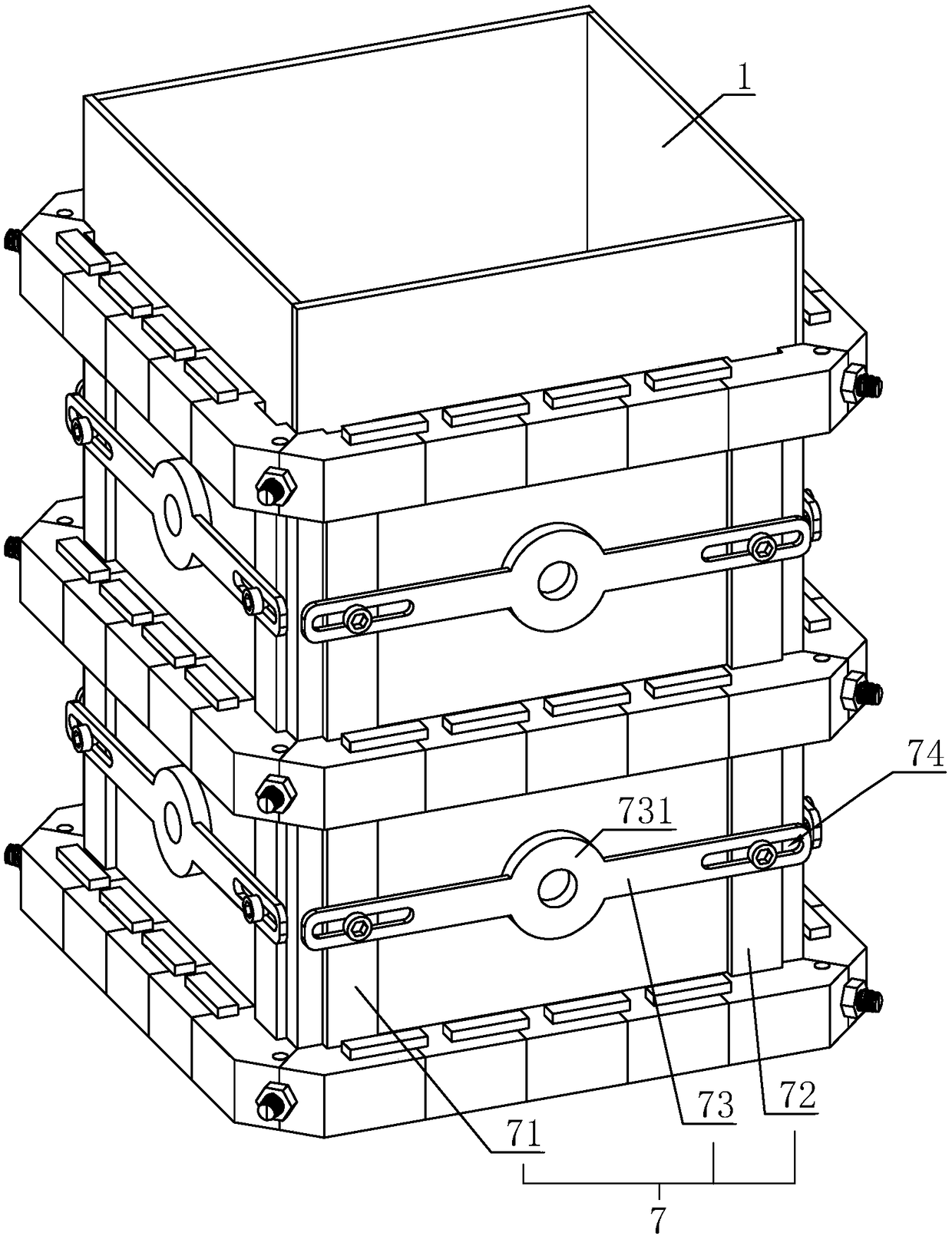

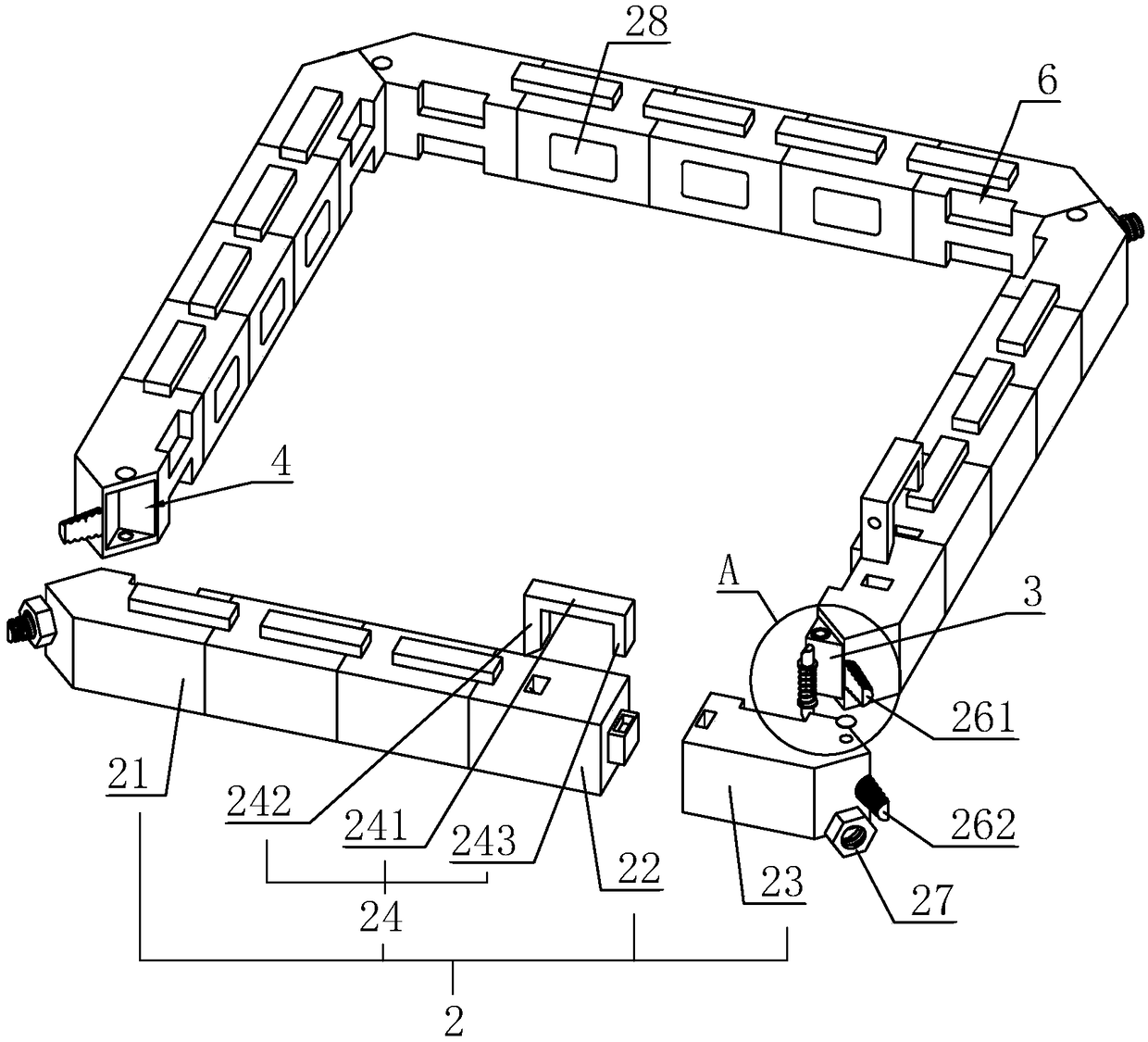

[0051] S2: Reinforce formwork 1, surround the four sides of the column formwork 1 with the pressing device, then insert the connecting component 7 into the pressing device, and then install another ring of pressing device, so as to be installed on the column formwork 1 alternately , and installed from the bottom of the column to the top of the column;

[0052] S3: Concrete pouring, pouring concrete into the pouring space, and pouring the area close to the formwork 1 first, and then pouring the steel bar area in the middle, and vibrating with a vibrating rod;

[0053]S4: dismantling, when the concrete reaches a certain ...

Embodiment 2

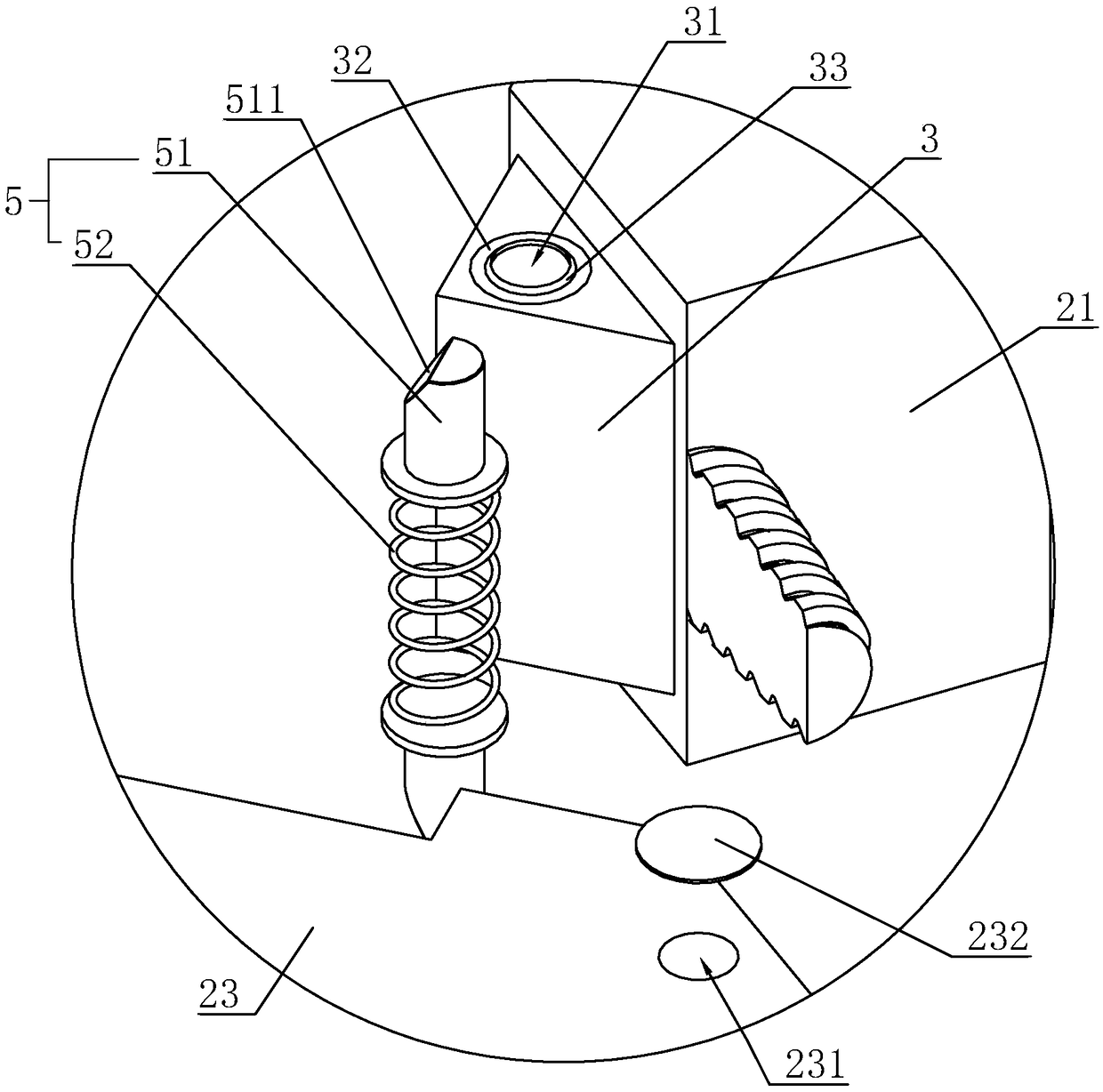

[0071] A fastening system for concrete rectangular column formwork, refer to Figure 5 The difference from Embodiment 1 is that: one end of the bottom of the block 3 that abuts against the slot 4 is provided with a locking slot 34 that is inclined upward, and the bottom of the slot 4 of the second fixing part 23 is provided with a locking slot 34 The slideways 233 are parallel and have the same cross section, and the opening of the slideway 233 is on the same level as the opening of the locking groove 34 . The second fixed part 23 is provided with a control hole 234 that is vertical and stepped and communicates with the slideway 233. The cross section of the end of the control hole 234 connected to the slideway 233 is larger than the cross section on the surface of the second fixed part 23. In the control hole A buffer chamber 235 is defined at the joint between the slideway 234 and the slideway 233 .

[0072] The locking assembly 5 includes a locking lever 81, an operating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com