Building concrete on-site pouring device

A technology of pouring on site and concrete, which is applied in construction, building structure, and processing of building materials. It can solve problems such as lack of fluidity, slow speed, and inconvenience, and achieve the goal of improving fluidity, increasing pouring speed, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

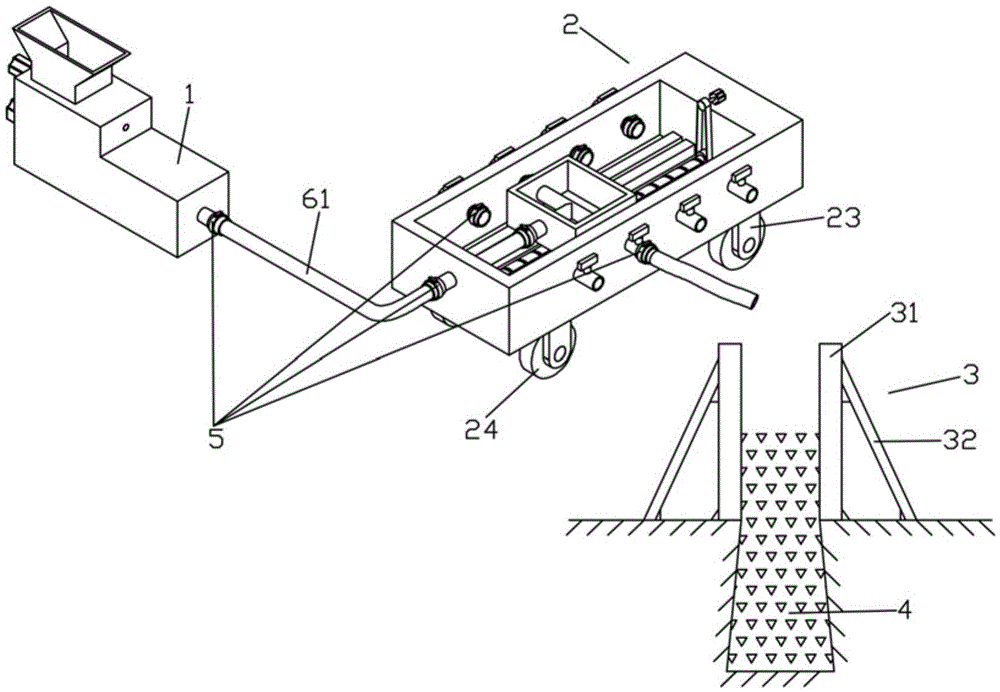

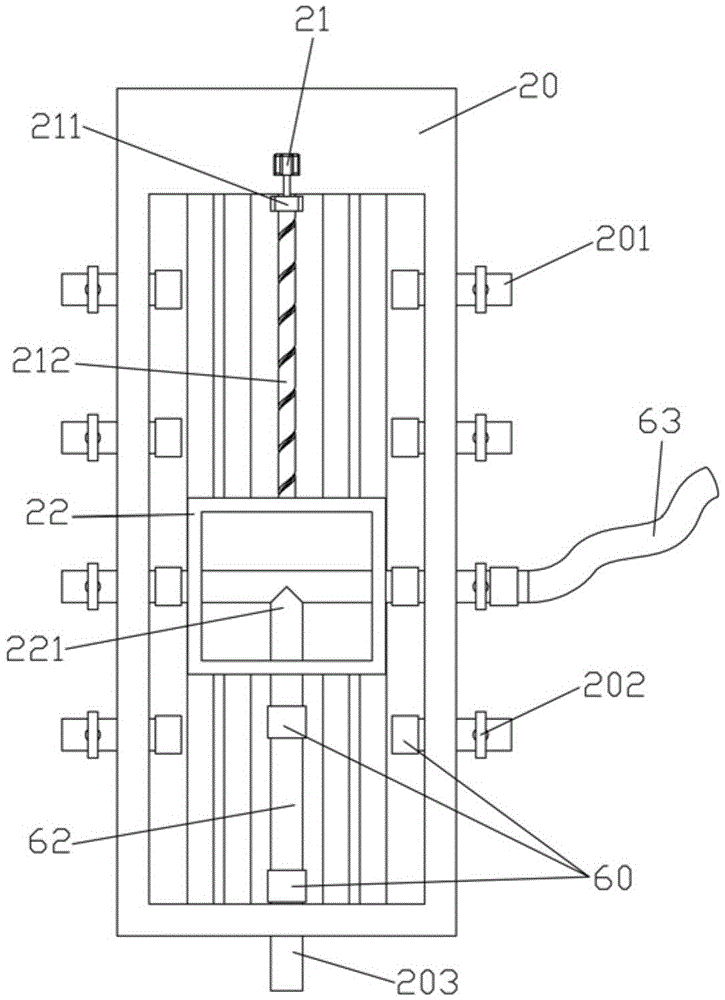

[0018] Such as Figure 1-2 As shown, the building concrete pouring device includes a concrete mixing tank, a mixing flow device 1, a pouring trolley 2, a wall fixing bracket 3 and a control device. The concrete mixing tank mixes sand and gravel, cement, water and additives. The concrete mixing tank Then connect the mixing flow device 1, the mixing flow device 1 is connected to the pouring trolley 2 through the delivery pipeline 61, the pouring trolley 2 moves back and forth between the stirring flow device 1 and the wall fixing bracket 3, and the concrete mixing tank and the pouring trolley 2 are in harmony with the control The device is electrically connected.

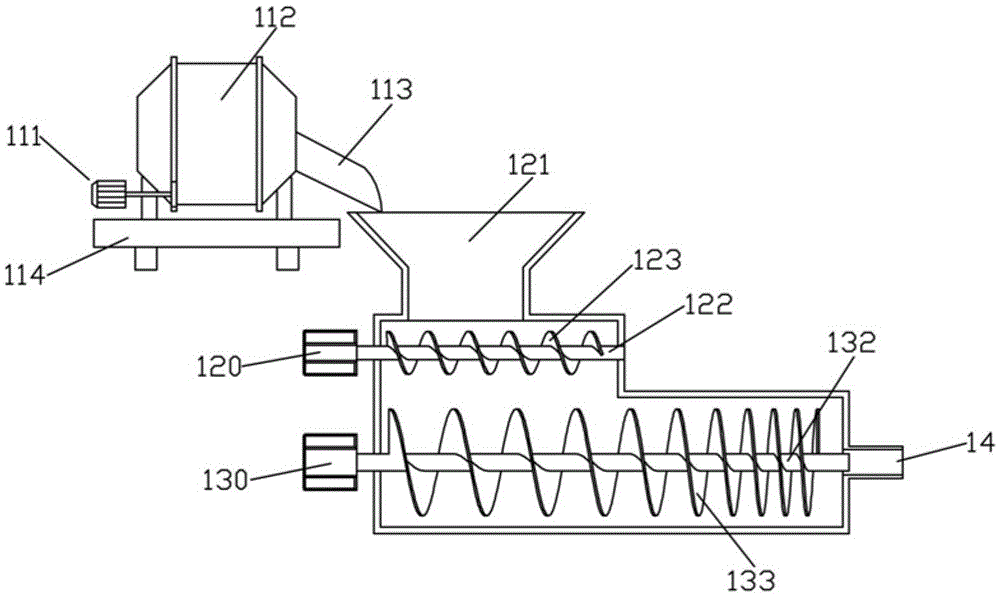

[0019] Such as figure 2 As shown, the concrete mixing tank includes a base 114, a stirring motor 111, a mixing tank body 112, and a discharge chute 113. The mixing tank body 112 is fixed on the base 114 through a bracket, and an agitator is arranged in the agitating tank body 112. Driven by the motor 11, the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com