Polishing-free highlight coating resin

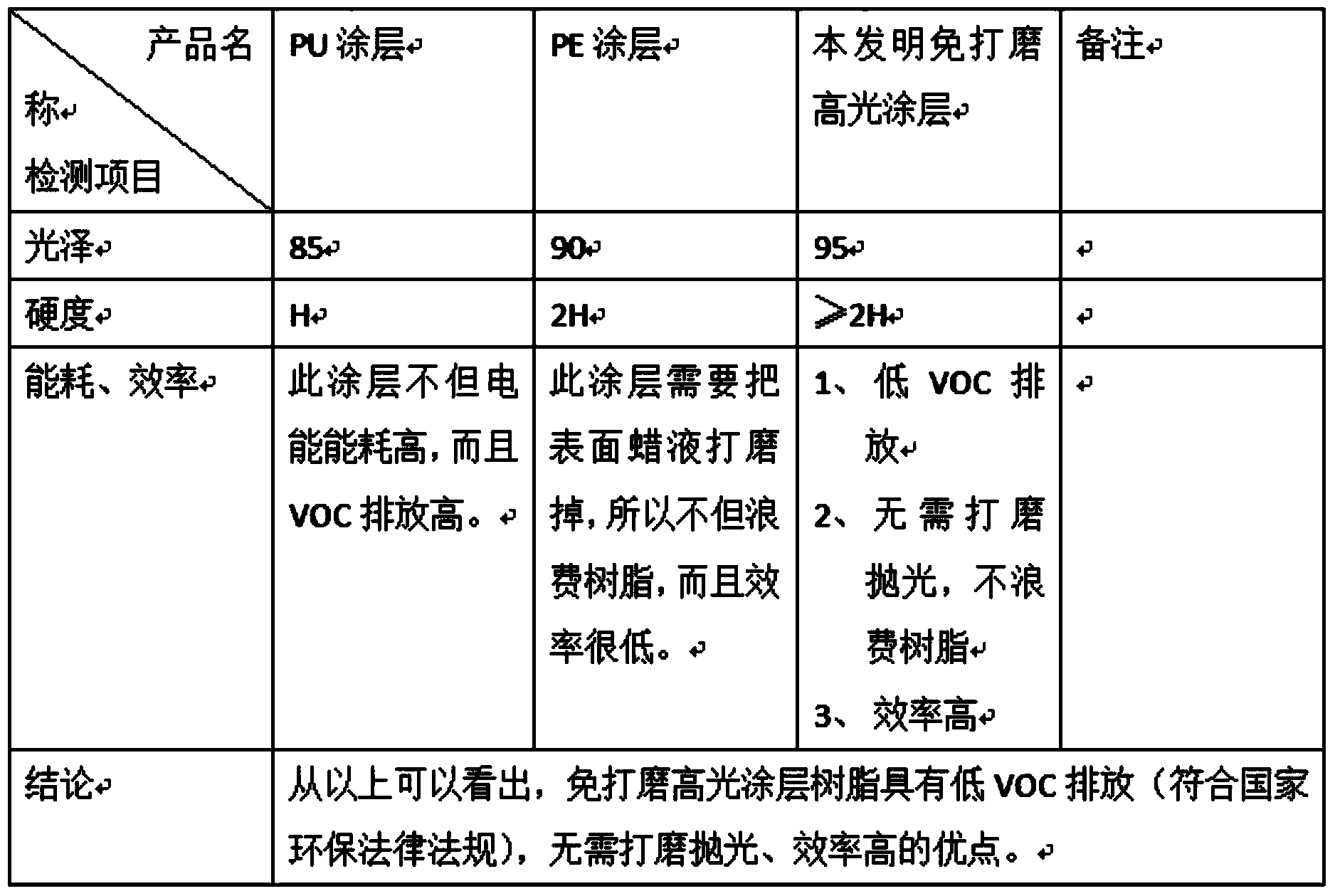

A coating resin and grinding-free technology, which is applied in the field of modified unsaturated polyester resin, can solve the problems of PU coating resin environmental pollution, poor hardness, and poor fullness, so as to reduce VOC emissions and resin The effect of reducing the amount of grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

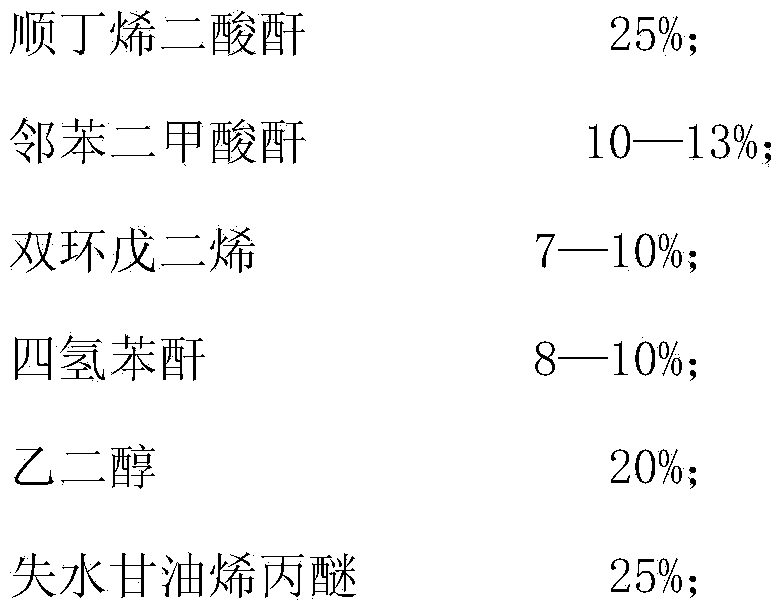

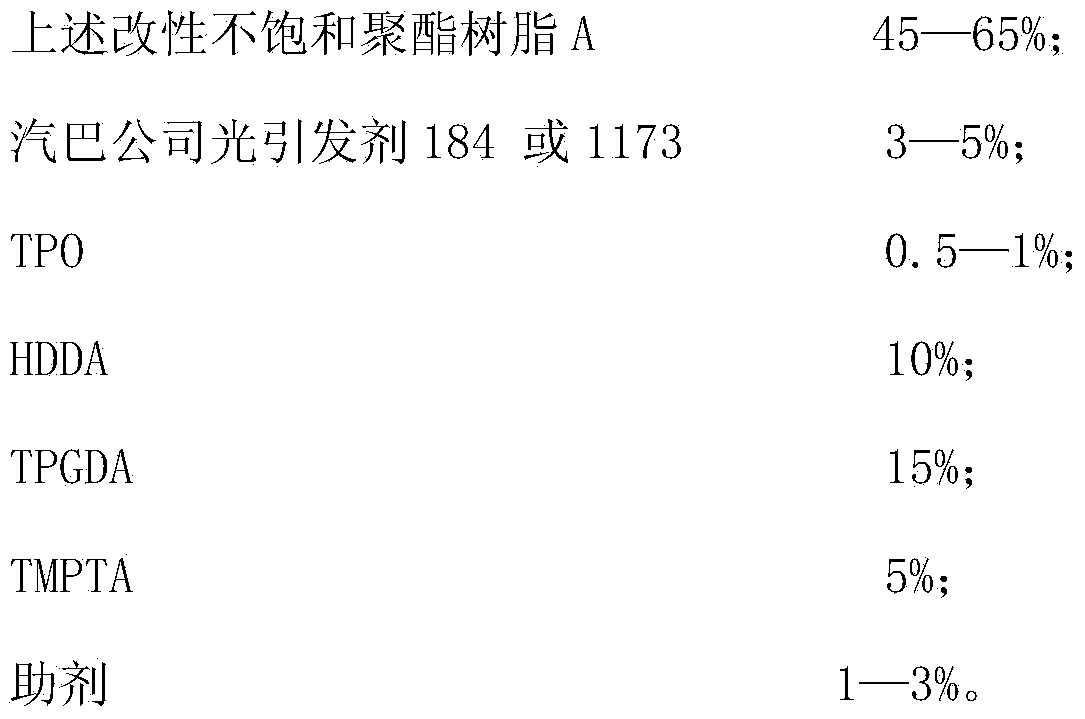

[0029] Weigh 250g of maleic anhydride, 10g of phthalic anhydride, 7g of dicyclopentadiene, 8g of tetrahydrophthalic anhydride, 20g of ethylene glycol, and 25g of glycerin allyl ether, and polycondense at about 180°C to obtain unsaturated Polyester resin, add diallyl ether 86 grams and mix well, set aside.

[0030] Take the resin 100g prepared in the previous step, add Ciba company photoinitiator 1846g, TPO1g, HDDA20g, TPGDA30g

[0031] TMPTA 10g, leveling agent and defoamer 2g, mixed to obtain the non-grinding high-gloss coating resin of the present invention.

[0032] During the use of this resin, the construction process is the same as that of ordinary photocurable coatings. But no sanding required.

Embodiment 2)

[0034] Weigh 250g of maleic anhydride, 13g of phthalic anhydride, 10g of dicyclopentadiene, 10g of tetrahydrophthalic anhydride, 20g of ethylene glycol, and 25g of glycerin allyl ether, polycondense at about 180°C, and react to obtain unsaturated Add 100 grams of diallyl ether to the polyester resin, mix well, and set aside.

[0035] Take 100g of the resin prepared in the previous step, add 1848g of Ciba photoinitiator, 2g of TPO, 22g of HDDA, 33g of TPGDA, 10g of TMPTA, 7.3g of leveling agent and defoamer, and mix to obtain the non-grinding high-gloss coating resin of the present invention.

[0036] During the use of this resin, the construction process is the same as that of ordinary photocurable coatings. But no sanding required.

Embodiment 3)

[0038] Weigh 250g of maleic anhydride, 12g of phthalic anhydride, 8g of dicyclopentadiene, 9g of tetrahydrophthalic anhydride, 20g of ethylene glycol, and 25g of glycerin allyl ether, and polycondense at about 180°C to obtain unsaturated Add 60 grams of diallyl ether to the polyester resin, mix well, and set aside.

[0039] Get 100g of resin prepared in the previous step, add Ciba company photoinitiator 1845g, TPO0.8g, HDDA17g, TPGDA25.5g, TMPTA8.5g, leveling agent and defoamer 1.5g, mix to obtain the non-grinding high-gloss coating of the present invention resin.

[0040]

[0041] During the use of this resin, the construction process is the same as that of ordinary light-cured coatings, but no grinding is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com