Integral molding method of composite material blade for wind power generation, and apparatus thereof

A composite material and forming method technology, applied in the field of blade forming, can solve the problems of high rigidity requirements, limited application, high cost, etc., and achieve the effect of high product precision, simple and efficient process, and less grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

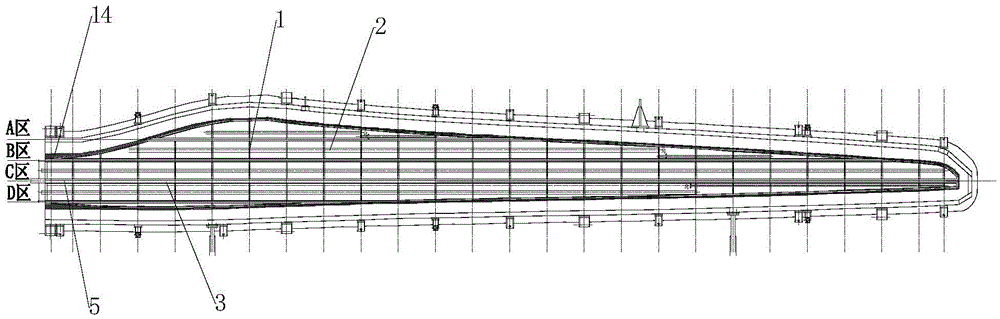

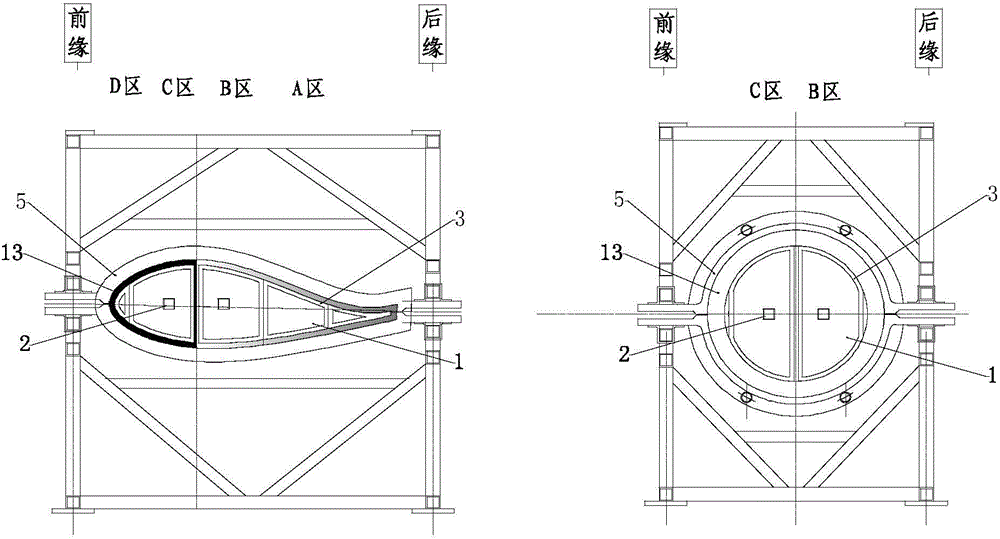

[0029] like Figure 1~2 As shown, the composite material blade integrated molding method for wind power generation adopts mold molding, and the mold 5 includes an upper mold, a lower mold and a core mold. It is characterized in that the method includes the following steps:

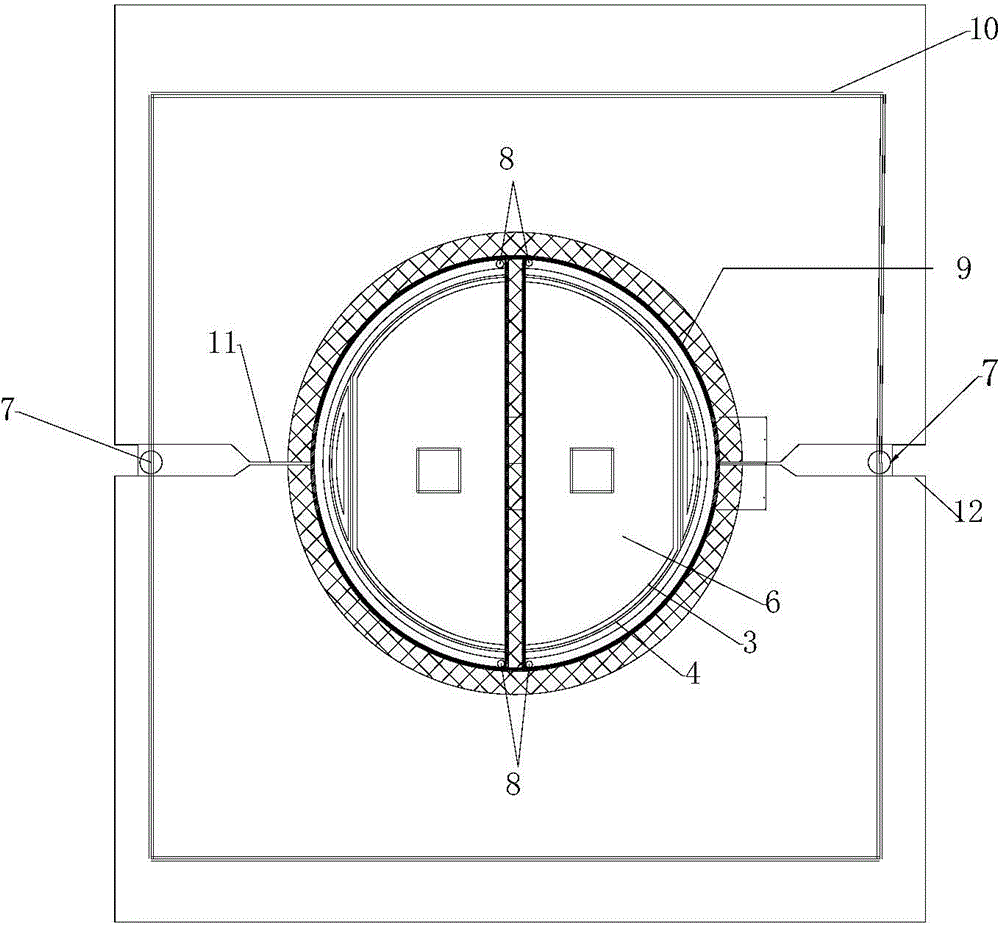

[0030] (1) Making the elastic mandrel: the mandrel is divided into 4 areas, each area is provided with mandrel clamps 1 matching the shape of the blades, the mandrel clamps 1 are connected in series with square tubes 2, and bolts are used to form each area respectively The mandrel, the sponge elastic body 3 and the vacuum bag film are sequentially wrapped around the mandrel in each area to form four elastic mandrels: the mandrel of A area, the mandrel of B area, the mandrel of C area and the mandrel of D area;

[0031] (2) Cleaning the mould: cleaning the upper mold and the lower mold with mold cleaning agent, sealing agent, mold release agent, and mold release wax;

[0032] (3) Lay fiber material and cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com