Polycrystalline silicon ingot slicing device and method

A technology of polycrystalline silicon ingots and silicon ingots, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., to improve the quality of ingots, avoid loss, and reduce grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

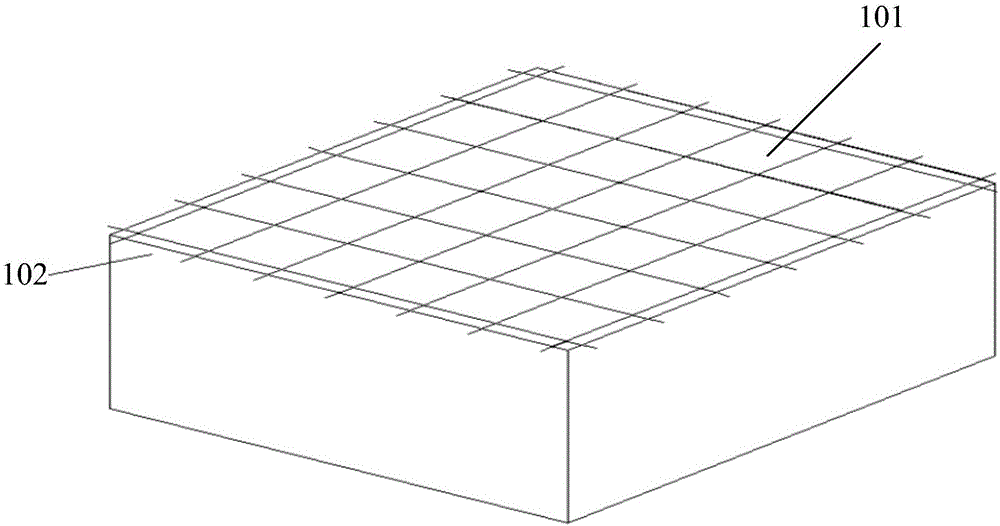

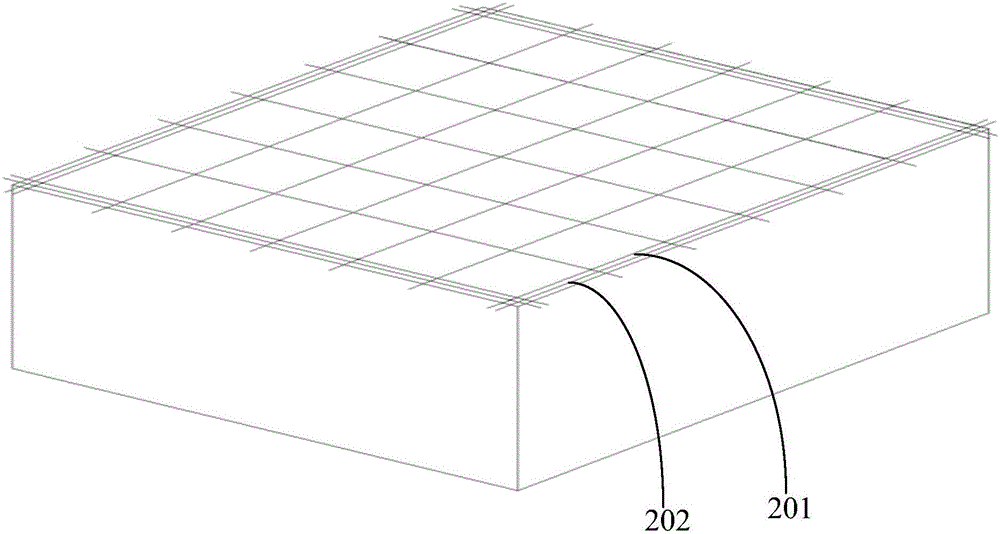

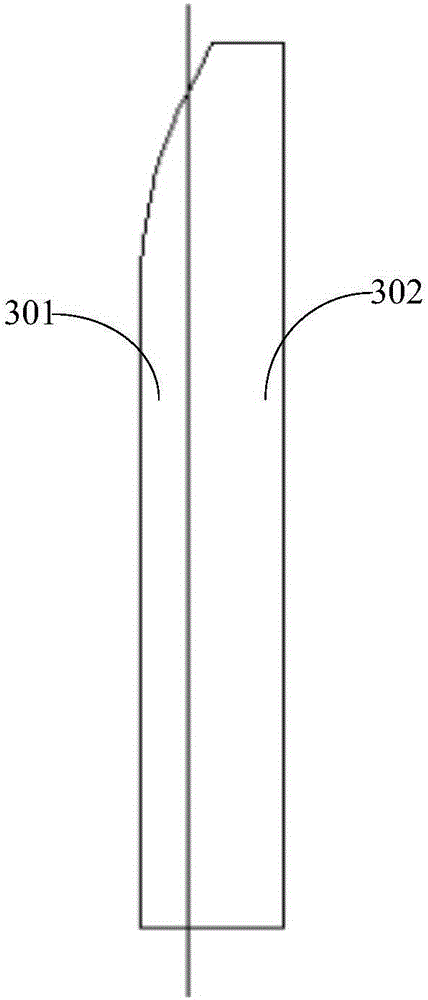

[0020] The core idea of the present invention is to provide a device and method for squaring polycrystalline silicon ingots. The edge skin material is divided into two parts, and the edge skin near the crucible surface has a relatively high impurity content. The edge skin near the center silicon ingot area can be recycled directly after cleaning, which can reduce the grinding of the edge skin close to the crucible surface, reduce impurities in the silicon material, improve the quality of the ingot, and avoid incomplete removal of impurities and dusty silicon material loss problem.

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com