Novel wheel electroplating spraying equipment

A technology of spraying equipment and wheels, which is applied in the direction of spraying booths, spraying devices, etc., can solve the problems of high labor intensity, short service life, and heavy workload of workers, so as to reduce labor intensity and workload, reduce overall production costs, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

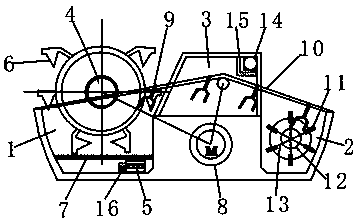

[0015] see figure 1 , the present invention provides a technical solution: a new type of wheel electroplating and spraying equipment, including an electroplating pool 1 and a painting booth 2, the electroplating pool 1 and the painting booth 2 are connected by a drying channel 3, and the top of the electroplating pool 1 A swivel frame 4 is installed, and the electroplating pool 1 includes a metal box 5 to be plated, a clip 6 to be plated and a barrier net 7, and the metal box 5 to be plated and the clip 6 to be plated are respectively arranged on both sides of the barrier net 7, and the metal box to be plated 5 is arranged below the barrier net 7, and the clamps 6 to be plated are arranged above the barrier net 7, and the number of the clamps 6 to be plated is six, and the six clamps 6 to be plated are mutually fixed at 60° and rotated. On the frame 4, the rotary frame 4 is driven by a motor 8, and an unloading frame 9 is provided on the rotation direction of the rotary frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com