Welding method for TKY joints of steel structure

A welding method and steel structure technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., to achieve the effects of reducing production costs, reducing cutting deformation, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

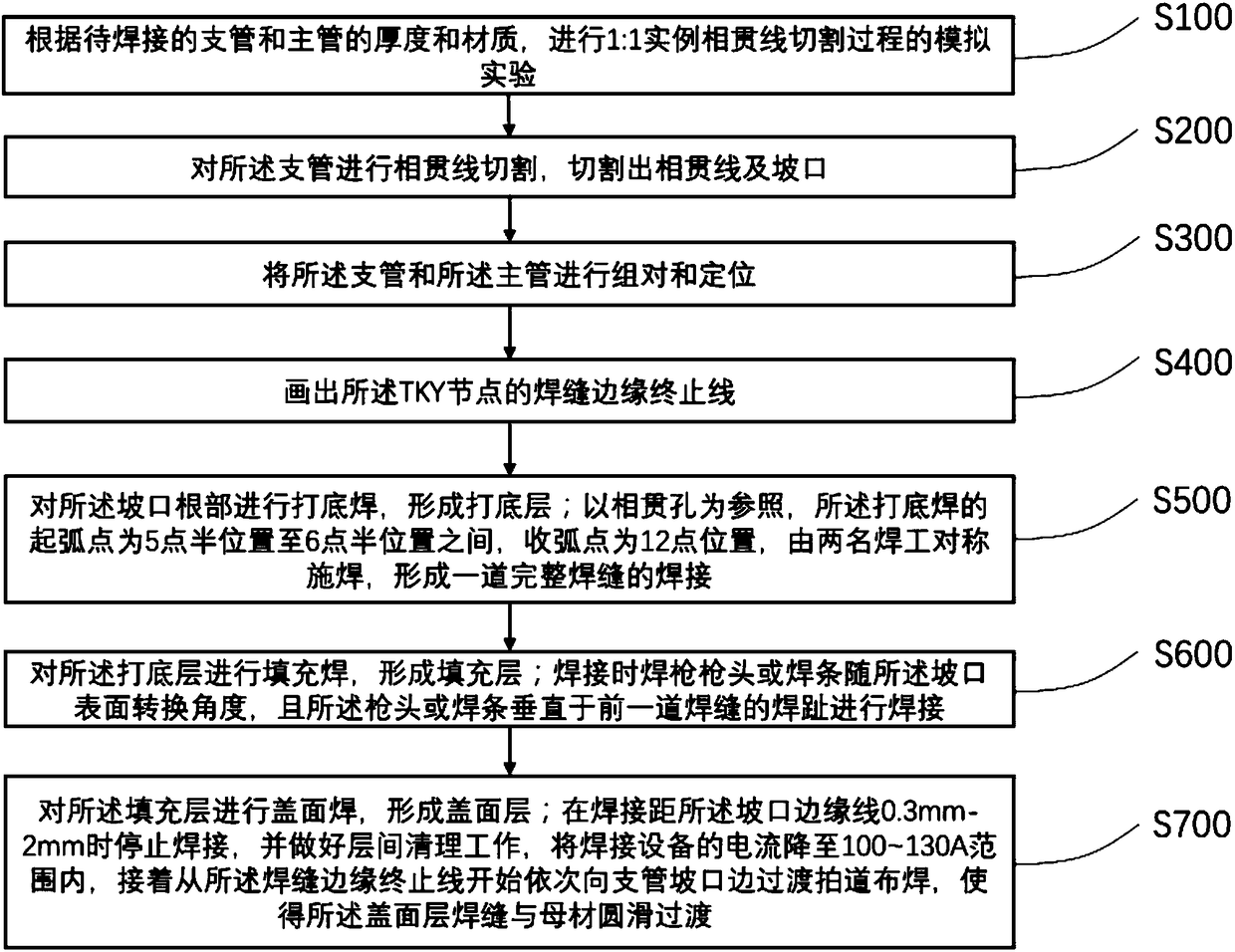

[0054] like figure 1 and Figure 5 shown, where figure 1 The flow chart of the welding method of the steel structure TKY node provided by the present invention comprises the following steps:

[0055] Step S100: According to the thickness and material of the branch pipe 2 and the main pipe 1 to be welded, a simulation experiment of a 1:1 example intersecting line cutting process is carried out;

[0056] Step S200: Carry out intersecting line cutting on the branch pipe 2, and cut out intersecting lines and bevels;

[0057] Step S300: pairing and positioning the branch pipe 2 and the main pipe 1;

[0058] Step S400: use a ruler tangent to the outer surface of the branch pipe 2 and extend toward the main pipe 1 to draw the end line of the weld edge of the TKY node;

[0059] Step S500: Perform backing welding on the root of the groove to form a backing layer; taking the intersecting hole as a reference, the starting point of the backing welding is between 5:30 and 6:30. The ar...

Embodiment 2

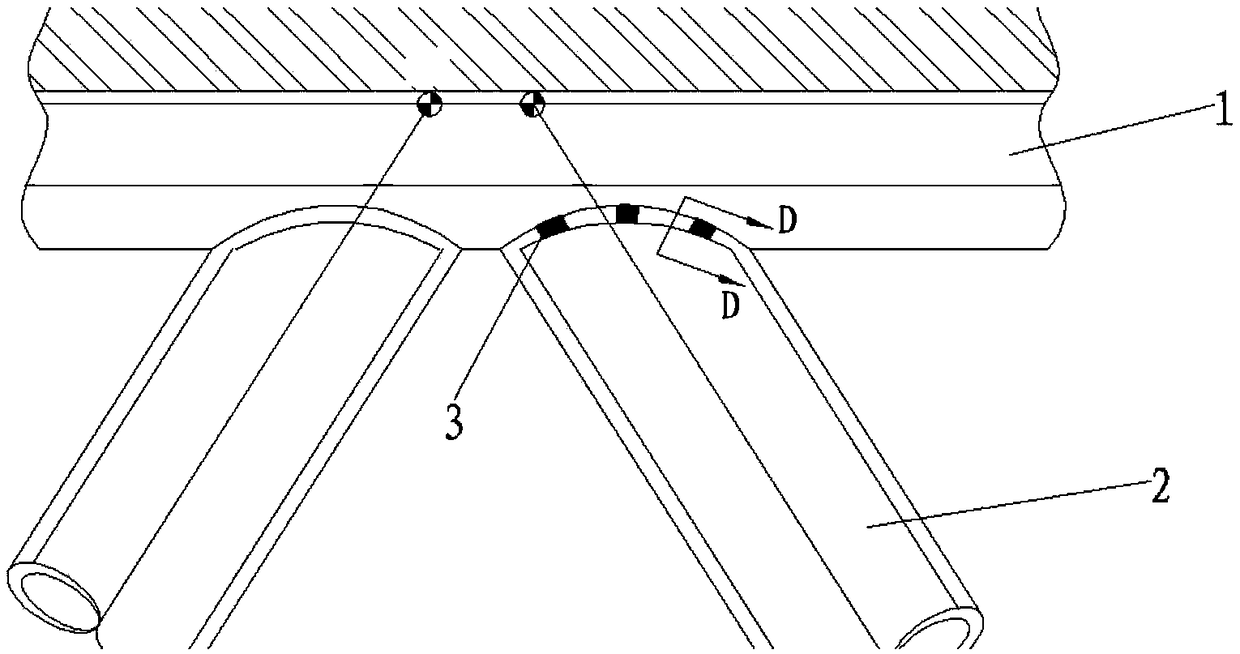

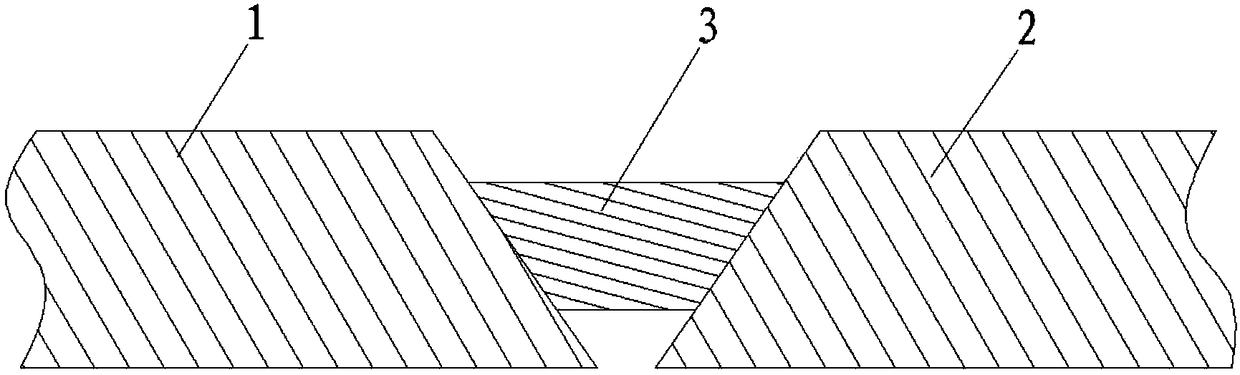

[0073] The welding method of the steel structure TKY node of this embodiment is basically the same as that of Embodiment 1, as Figure 5 As shown, the steel structure TKY node in this embodiment is a Y-shaped node, such as Figure 4 to Figure 9 As shown, it is a schematic diagram of each area of the steel structure TKY node in this embodiment and its corresponding welding situation. The above-mentioned welding method of the steel structure TKY node is used for single-sided welding and double-sided forming, which specifically includes the following steps:

[0074] Step S100: According to the thickness and material of the branch pipe 2 and the main pipe 1 to be welded, a simulation experiment of the intersecting line cutting process of a 1:1 example is carried out to determine the cutting parameters and cutting allowance; The specification requires preheating. The amount of preheating will directly affect the shape and accuracy of the intersecting line incision. Therefore, a 1...

Embodiment 3

[0092] The welding method of the steel structure TKY node of this embodiment is basically the same as that of Embodiment 2, the difference is that the steel structure TKY node welded in this embodiment is a K-shaped node, such as figure 2 shown.

[0093] Of course, without loss of generality, the welding method of steel structure TKY joints provided by the present invention can also be applied to other types of joint welding, and the corresponding welding parameters can be adjusted according to the materials and sizes of materials used in different steel structures, and better results can also be obtained. welding effect.

[0094] Compared with prior art, the present invention has following advantage:

[0095] 1. The welding method of the steel structure TKY joint of the present invention is easy to operate, one-time welding is formed, the weld seam and the base metal are smoothly transitioned, the grinding of the weld seam is reduced, and the fatigue strength and other mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com