Non-joint wire embedding device for random-embedded windings of large-power motor stator and wiring method

A technology of motor stator and wiring method, which is applied to electromechanical devices, electric components, and manufacturing of motor generators, etc., can solve the problems of difficult to guarantee product quality, many intermediate nodes, and complicated manufacturing process of high-power motor stator coils. Good performance, high anti-halation effect, saving material and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

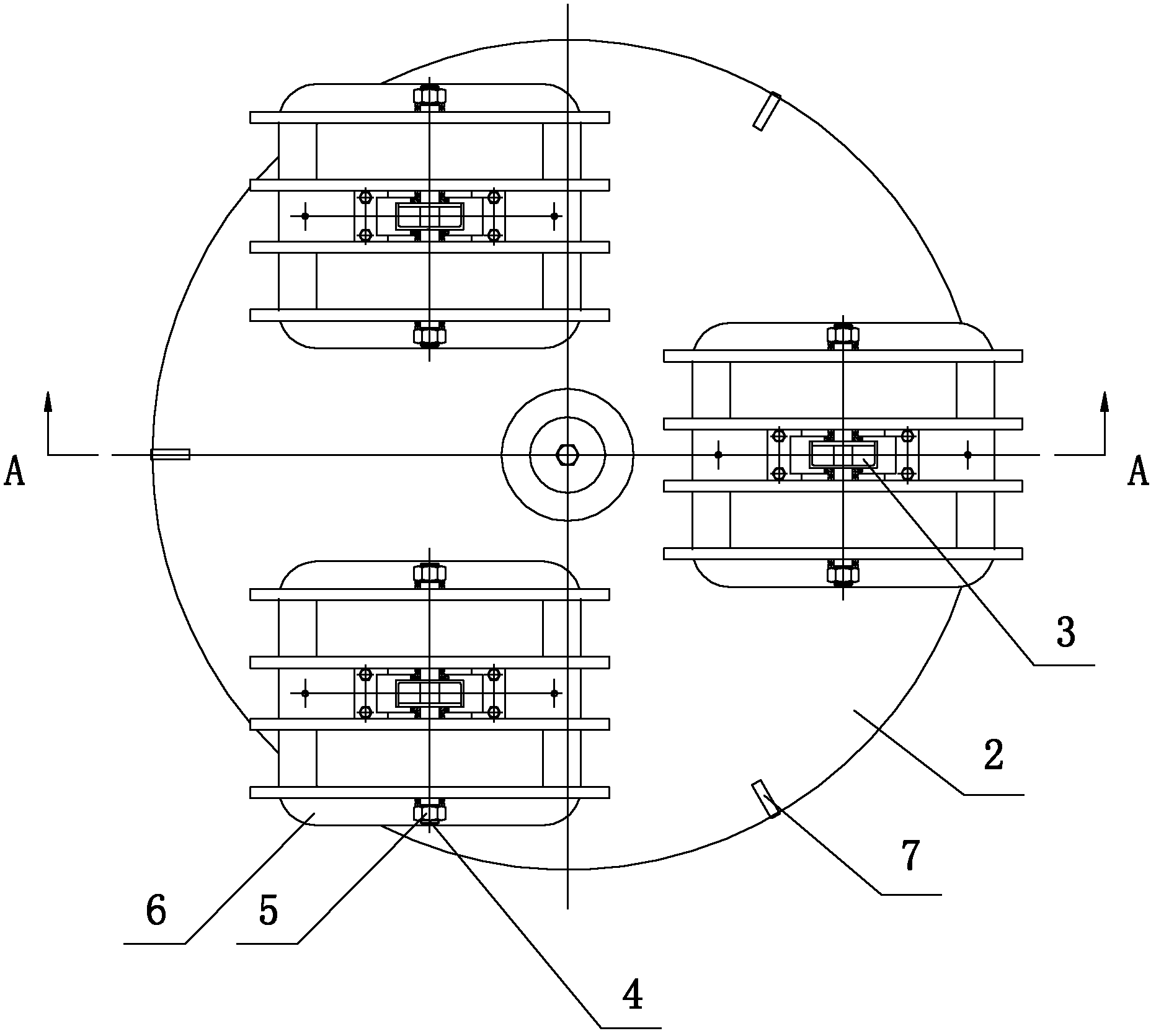

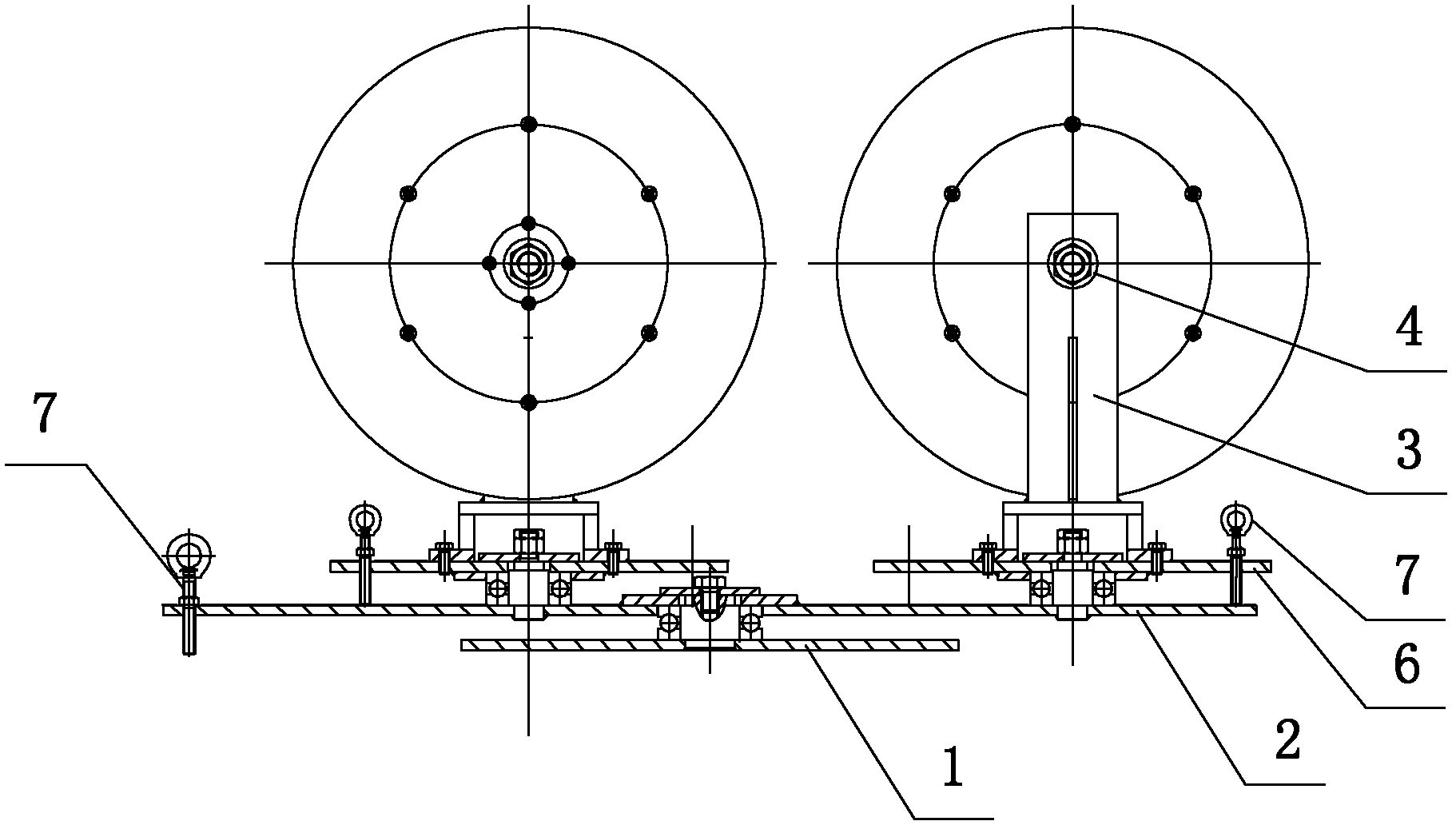

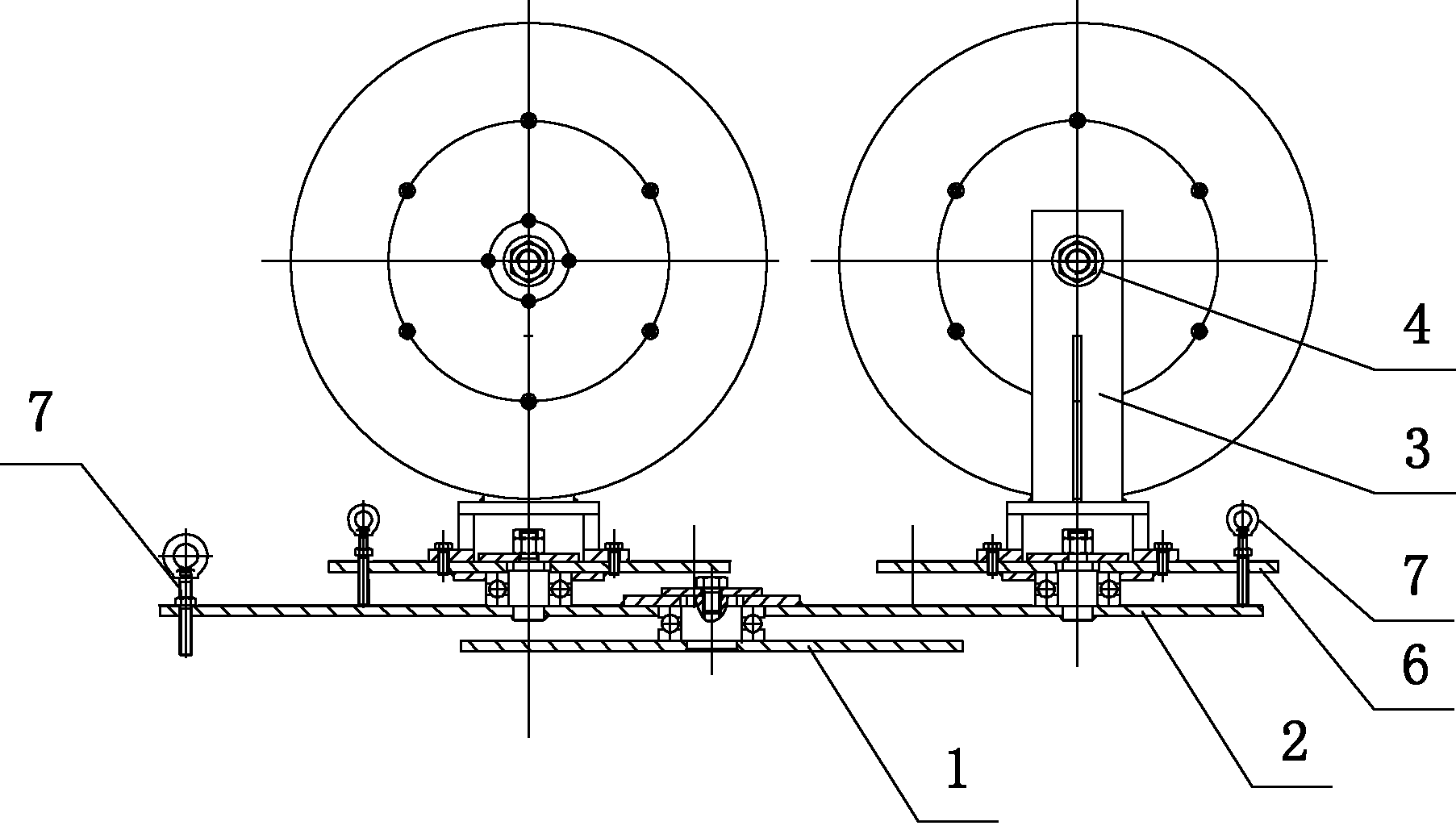

[0021] refer to figure 1 , figure 2 It is an embodiment of the nodeless wire embedding device and wiring method of the stator loosely embedded winding of the high-power motor of the present invention. The nodeless wire embedding device of the stator loosely embedded winding of the high-power motor includes a base 1 on which the first Supporting plate 2, said first supporting plate 2 is connected with at least three pay-off racks 3, and each pay-off rack 3 is provided with a horizontal pay-off rod 4, and said pay-off rod 4 passes through the pay-off Frame 3, the middle part of the pay-off rod 4 is connected with the pay-off frame 3, the two ends of the pay-off rod 4 are provided with fixing devices 5, and each pay-off frame 3 is fixed on a second pallet 6, the second supporting plate 6 is connected with the first supporting plate 2, the first supporting plate 2 is circular, and there are three pay-off racks 3, and the three pay-off racks 3 are evenly distributed on the On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com