Scroll compressor

A scroll compressor and scroll tooth technology, applied in the field of scroll compressors, can solve the problems of unable to suppress refrigerant leakage and increase the gap area, so as to reduce refrigerant leakage, ensure reliability and reduce the gap Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021]

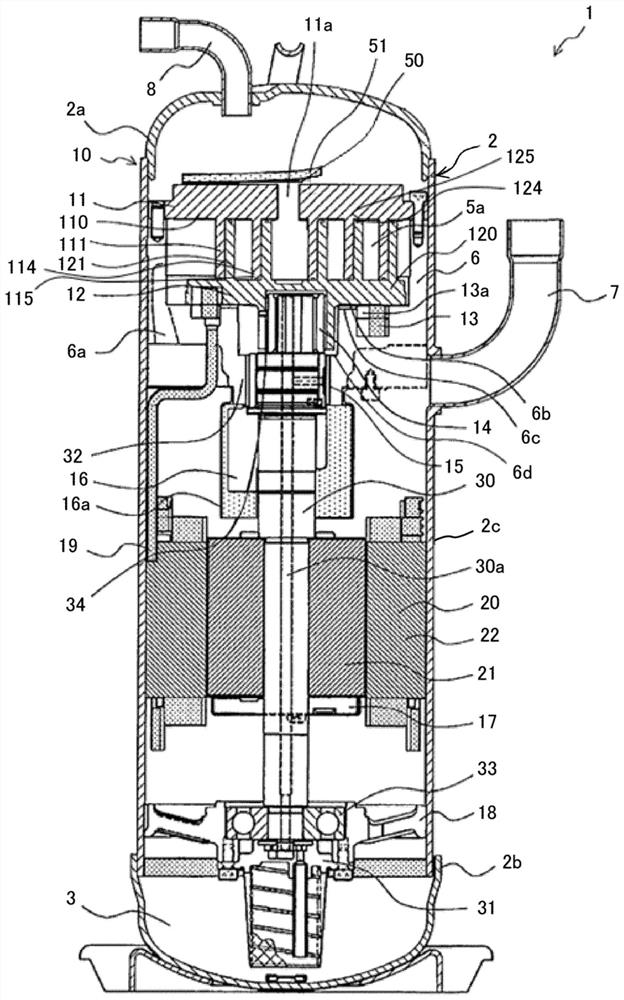

[0022] refer to figure 1 The scroll compressor 1 according to Embodiment 1 of the present invention will be described. figure 1 It is a longitudinal cross-sectional view schematically showing the scroll compressor 1 according to the first embodiment. Such as figure 1 As shown, the scroll compressor 1 includes a compression mechanism unit 10 and a motor 20 as a motor unit that drives the compression mechanism unit 10 inside a casing 2 that is a hermetic container.

[0023] The casing 2 has an upper casing 2 a , a lower casing 2 b , and a main body casing 2 c to constitute a casing of the scroll compressor 1 , and has an oil reservoir 3 at a lower portion. The housing 2 is cylindrical with a bottom, and the upper part of the main body housing 2c is closed by the dome-shaped upper housing 2a, and the lower part of the main body housing 2c is closed by the lower housing 2b.

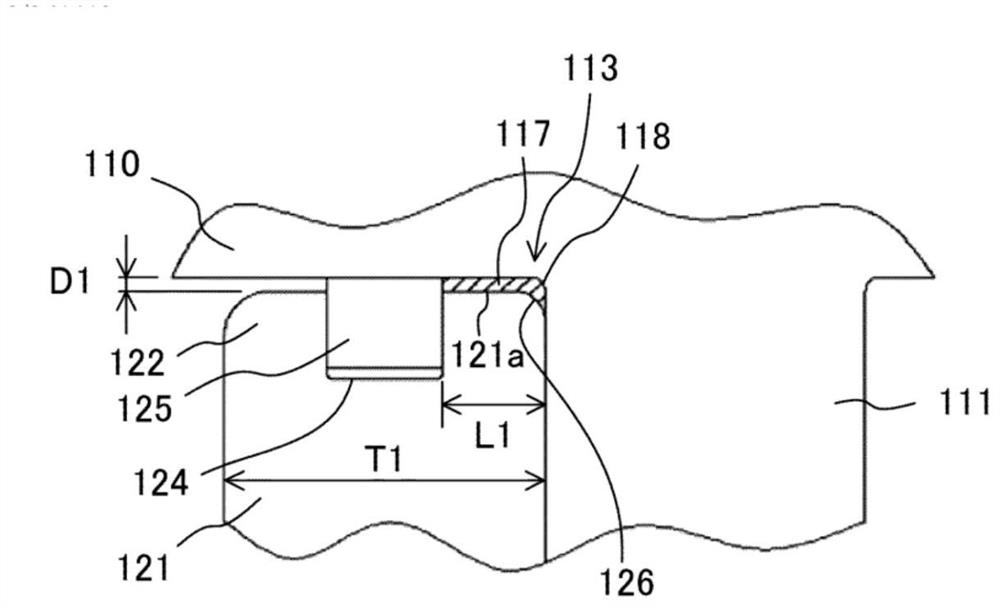

[0024] The compression mechanism unit 10 is configured to include a fixed scroll 11 and an o...

Embodiment approach 2

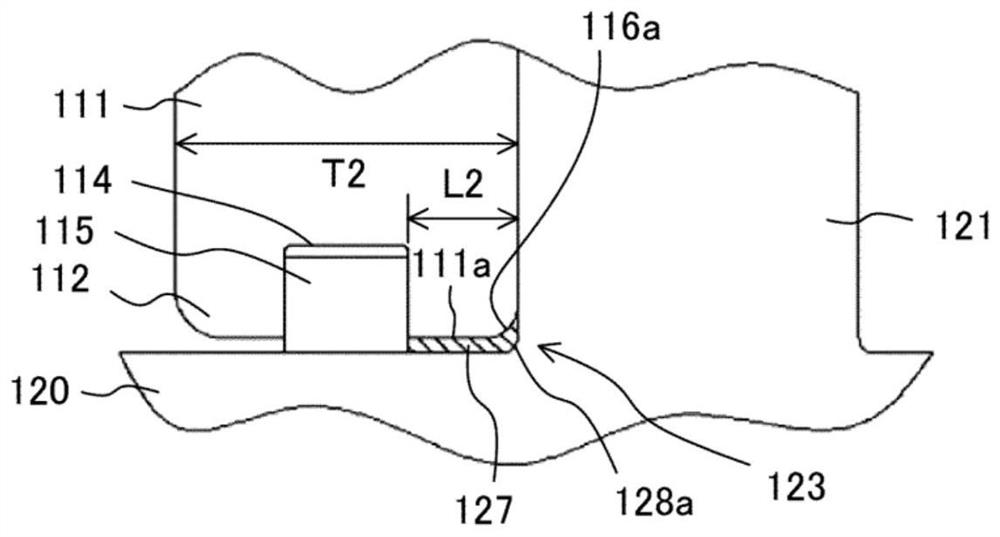

[0070] Next, refer to Figure 6 Embodiment 2 of the present invention will be described. Figure 6 It is a plan view showing the orbiting scroll 12 of the scroll compressor 1 according to the second embodiment. In addition, here, the same code|symbol is attached|subjected to the same component as Embodiment 1 mentioned above, and the detailed description is abbreviate|omitted.

[0071] Such as Figure 6 As shown, in the second embodiment, the second swing-side base curved portion 128b of the swing scroll 12 is formed at a center-side end point 130a of the outer involute curve 130 in the wrap tooth 121 as a starting point and on the inner side. The outer peripheral end point 131b of the involute curve 131 is the range of the first arc portion 132 and the second arc portion 133 that end. That is, in the second embodiment, the second swing-side base curved portion 128 b of the swing scroll 12 is formed to extend into the wrap 121 beyond the range including the first arc portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com